Biaxial drawing-pressing test part with matrix fiber bundle and preparation method thereof

A technology of matrix fibers and test pieces, which is used in the preparation of test samples and the application of stable tension/pressure to test the strength of materials, etc., to simplify the loading device, reduce costs, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] The preparation method of the biaxial tension-compression test piece with matrix fiber bundle of the present invention comprises the following steps:

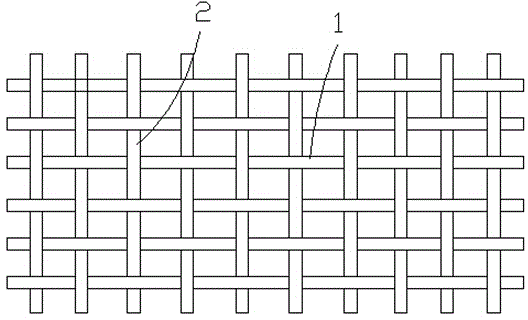

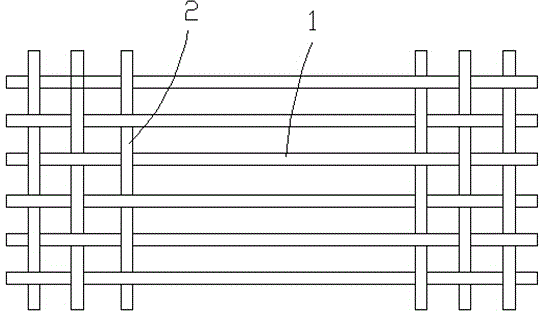

[0031] Step 1, applying the principle of periodicity to prepare a single-layer prefabricated body with matrix fiber bundles. In order to ensure that the shape of the matrix fiber bundle in the sample is consistent with that in the real composite material, the two-dimensional woven fiber cloth ( figure 1 ) The weft fiber 2 in the middle section is drawn out, leaving only the warp fiber 1, and the periodicity of the warp fiber should not be disturbed during the process of extracting the weft fiber;

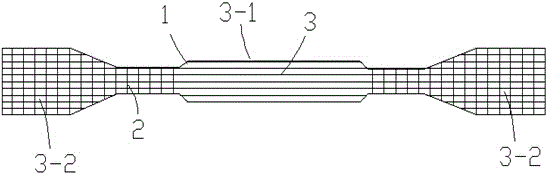

[0032] Step 2, the fiber cloth obtained in step 1 ( figure 2 ) are stacked along the thickness direction and fixed on the mold, and the matrix is deposited repeatedly to obtain a flat plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com