An automatic inflow control device performance testing system and method

A technology of inflow control and testing system, which is applied in the field of petroleum engineering to achieve the effect of saving experimental materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

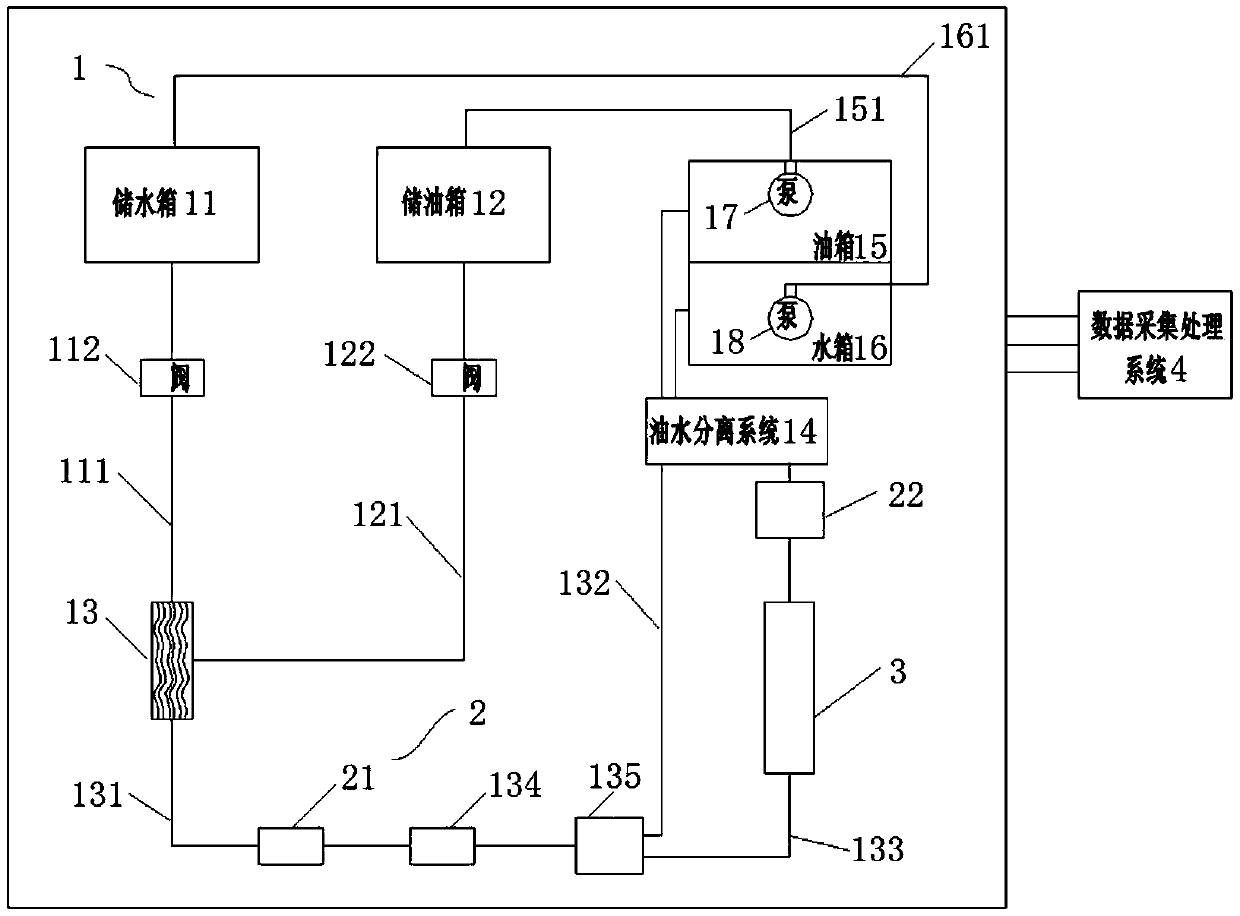

Method used

Image

Examples

Embodiment 1

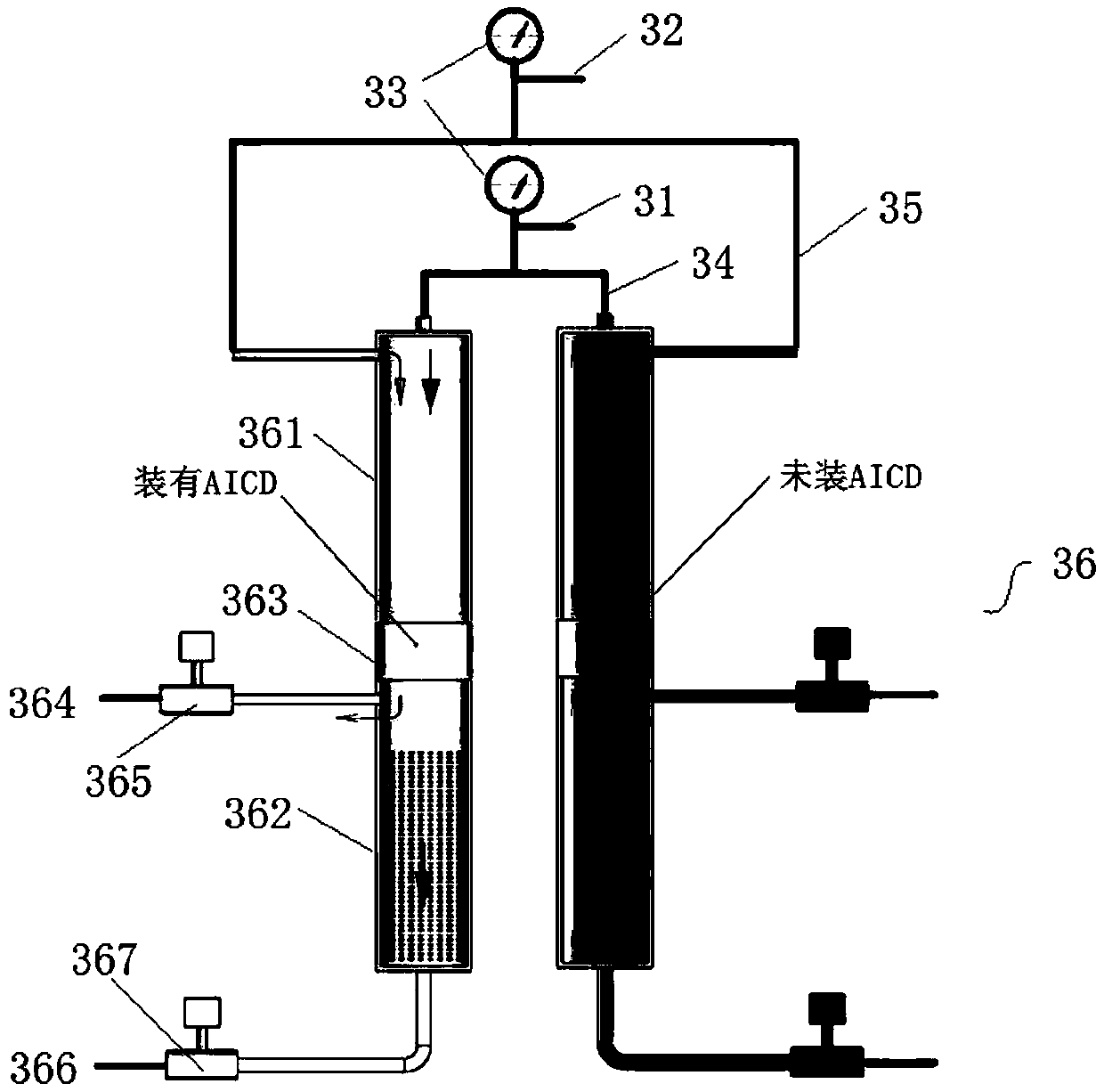

[0046] This embodiment takes comparative observation test as an example to further introduce the invention.

[0047] 1) Install two tempered glass test equipment, one is a tempered glass tube installed in the automatic inflow control device, and the other is a tempered glass tube installed in a conventional nozzle. The pressure inside the cylinder is the same on both sides. The barrel diameters on both sides are exactly the same.

[0048] 2) Turn on the circulation system, so that the single-phase fluid in the water storage tank or oil storage tank enters from the liquid inlet of the tempered glass test equipment and flows out from the liquid outlet under the pump pressure.

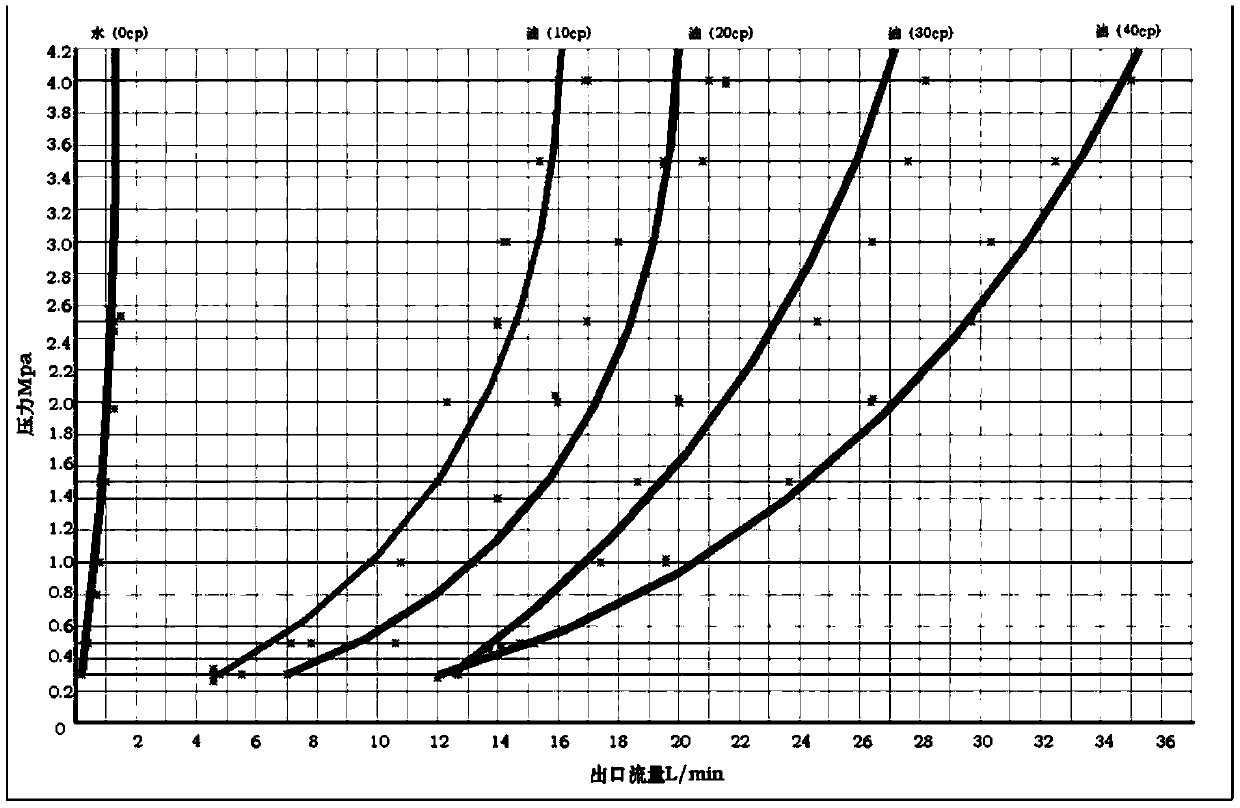

[0049] 3) When the liquid is oil (such as viscosity 1-150Cp), after the value is stable, record the outlet flow of the two tempered glass tubes (due to the high viscosity and low flow rate of the oil, the oil flow into the automatic inflow control device is not controlled. Therefore, the two flowmeters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com