Shale gas pool hydraulic fracturing sand-adding technology

A hydraulic fracturing and shale gas reservoir technology, applied in the field of hydraulic fracturing, can solve problems such as large fluctuation range of construction pressure, incorrect sanding method, and difficulty in sanding, so as to eliminate the impact of formation blockage and ensure construction displacement Requirements, improve the effect of the overall amount of sand added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

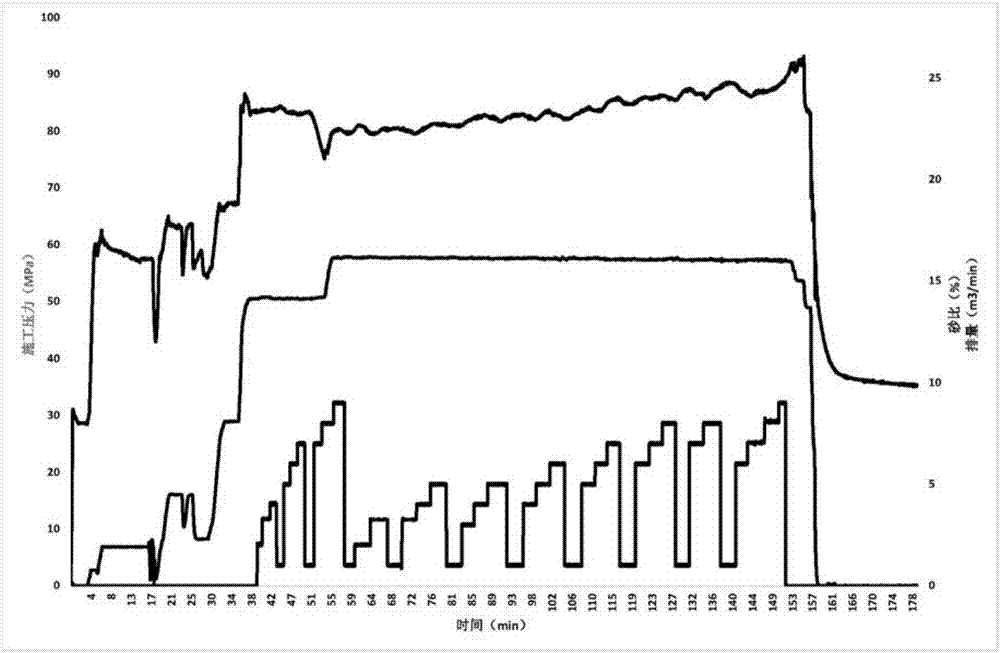

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] A schematic diagram of a shale gas reservoir hydraulic fracturing sand adding process of the present invention is as follows figure 1 shown.

[0029] A kind of shale gas reservoir hydraulic fracturing sand adding process of the present invention comprises the following stages:

[0030] (1) Pickling: Acid washing is performed on the perforation area and the near-well zone to remove the blockage around the perforation hole and the near-well zone. By acidizing and flushing the perforation area and the near-well zone, the blockage around the perforation hole and the near-well zone is removed to reduce the construction pressure. After the construction pressure is reduced, the step-up displacement is designed, and the construction displacement is changed from 2m according to the pressure change. 3 / min Stairs raised to 14m 3 / min or more, large-displacement hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com