Ultra-deep foundation pit supporting method

A deep foundation pit support and foundation pit technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as inability to meet the needs of ultra-deep foundation pits, achieve both investment cost and bearing capacity, and ensure structural strength and safety , to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

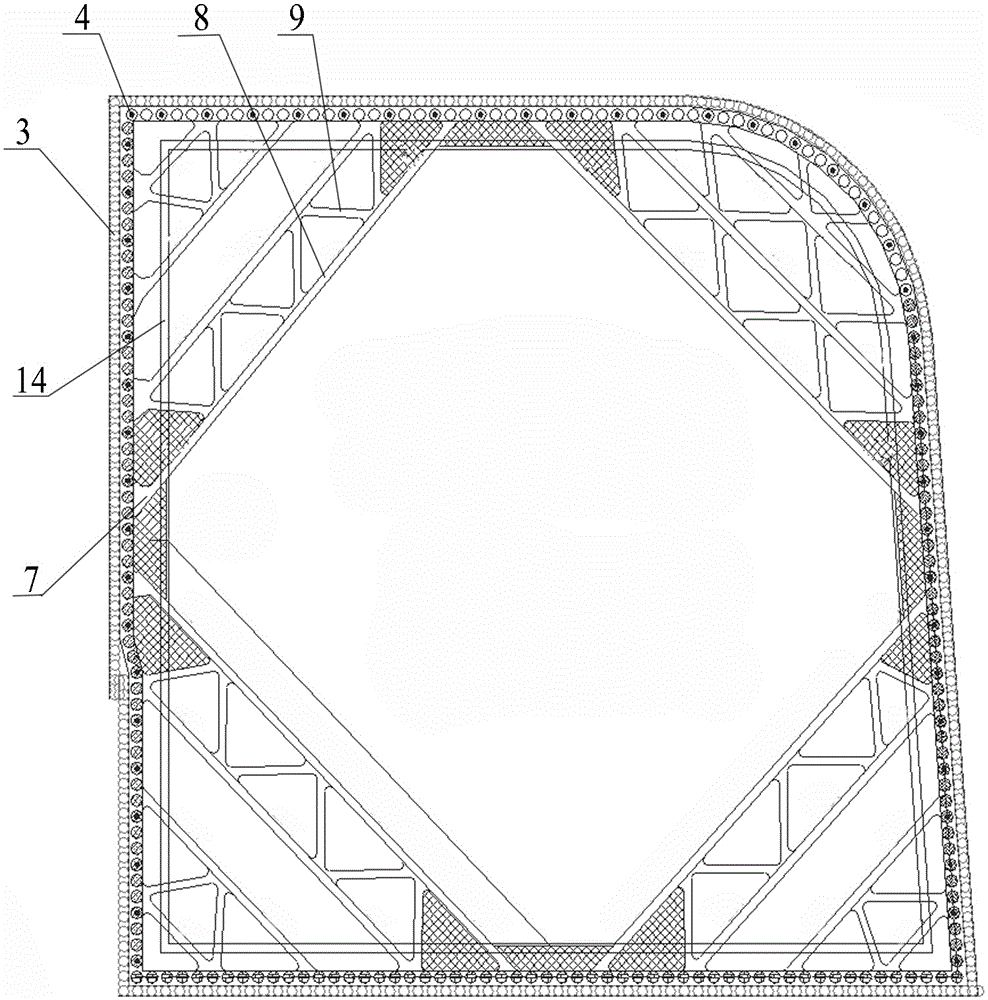

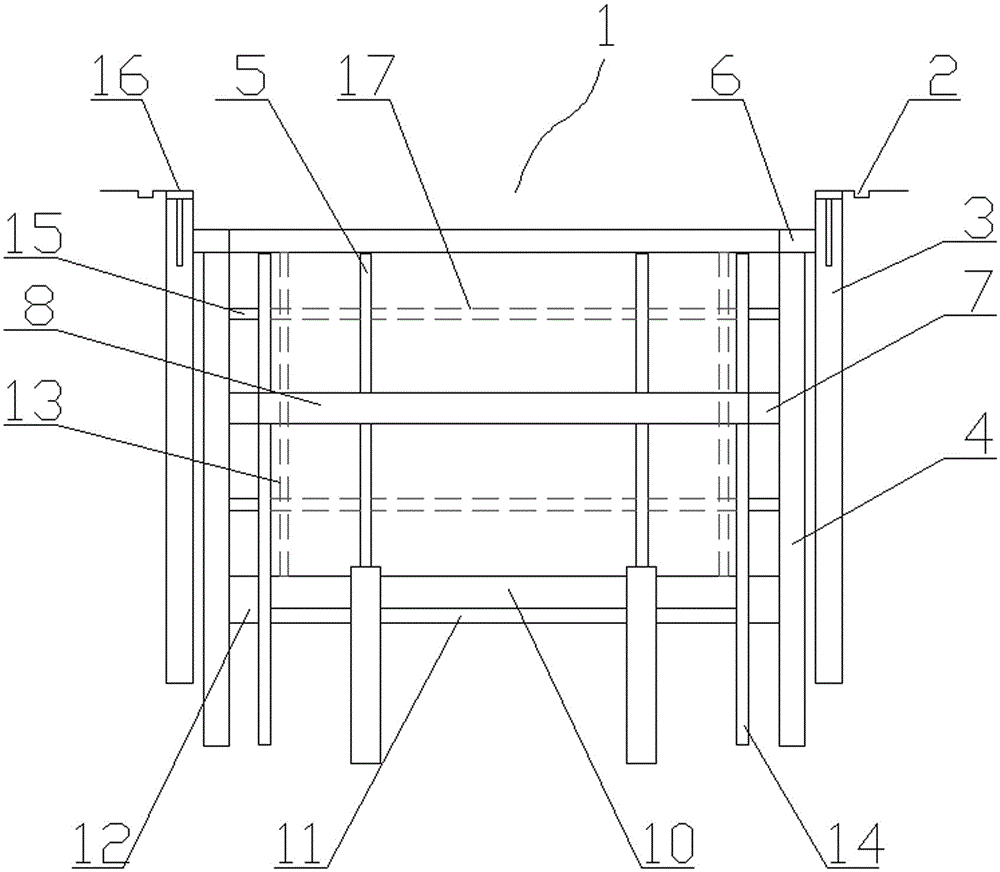

[0028] figure 1 , 2 Shown: an ultra-deep foundation pit support system includes a single-row three-axis deep-stirred pile water-stop curtain 3, a bored pile 4 and a steel column 5, and the single-row three-axis deep-stirred pile water-stop curtain 3 is lower than the natural ground The surrounding protection is set along the foundation pit 1, the top of the single-row three-axis deep-stirring pile water-stop curtain 3 extends through the steel pipe into the single-row three-axis deep-stirring pile water-stop curtain to pull and press the top plate 16, and multiple bored piles 4 They are arranged at intervals in the foundation pit 1 on the inner side of the water-stop curtain 3 of single-row three-axis deep-stirring piles. In the foundation pit 1 on the inner side of the bored pile 4, the steel column is an angle steel lattice column, and the lower part of the steel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com