Full Casing Azimuth Drilling Rig

A full-rotary drilling rig and full-casing technology, applied in rotary drilling rigs, rotary drilling, earthwork drilling and mining, etc., can solve problems such as poor alignment of crawler excavators, difficulty in ensuring verticality, and affecting engineering quality, etc., to achieve Wide application, long service life and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

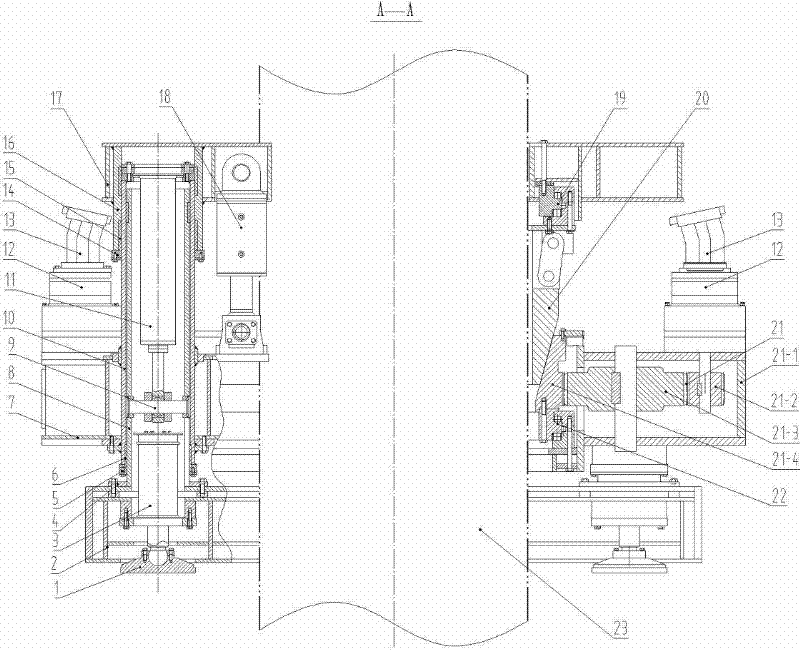

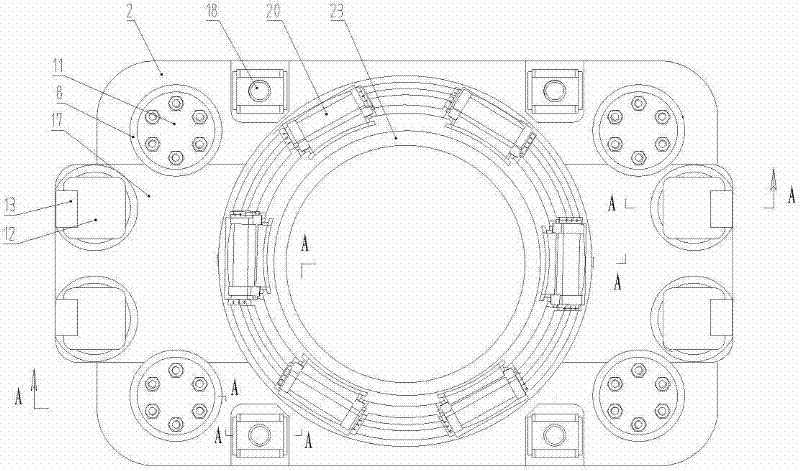

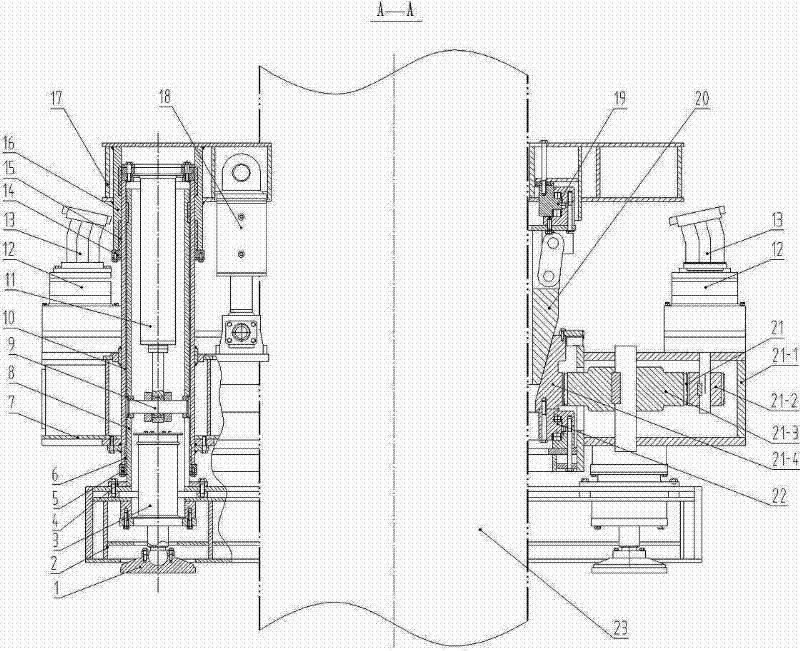

[0019] like figure 1 , 2 Shown: a full-casing full-rotation drilling rig, characterized in that it includes: a base 2, a power support platform 7, a lifting platform 17, a column 8, a casing clamping device 20, a casing pulling cylinder 11, and a hydraulic motor 13 , the gearbox 12 and the gear transmission 21 that drives the sleeve 23 to rotate. The base 2 is a steel rectangular frame, and the lower end of the base 2 is provided with supporting legs 1 . The uprights 8 are four circular tubes, and the four uprights 8 are vertically fixed on the four corners of the base 2 . The dynamic support platform 7 is a rectangular frame of steel structure. Four guide tubes I10 are fixed on the dynamic support platform 7. The guide tubes I10 are slip-fitted and inserted on the column 8. The guide tube I10 pulls the oil cylinder 11 and the column 8 through the casing. connect. The lifting platform 17 is a rectangular frame of steel structure. Four guide tubes II16 are fixed on the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com