Stair connecting piece, manufacturing method, aluminum formwork system utilizing stair connecting pieces and stair construction method

An aluminum formwork and connector technology, which is applied in the field of stair construction and aluminum formwork system, can solve the problems of inability to guarantee construction safety, prone to safety accidents, and inability to splicing walls, so as to eliminate hidden dangers in construction safety, facilitate construction, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

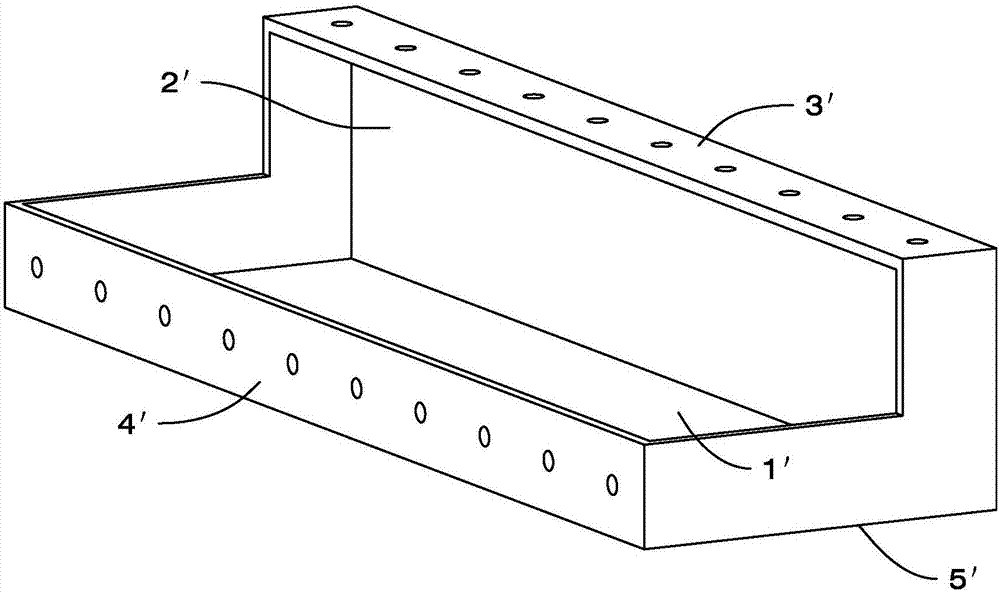

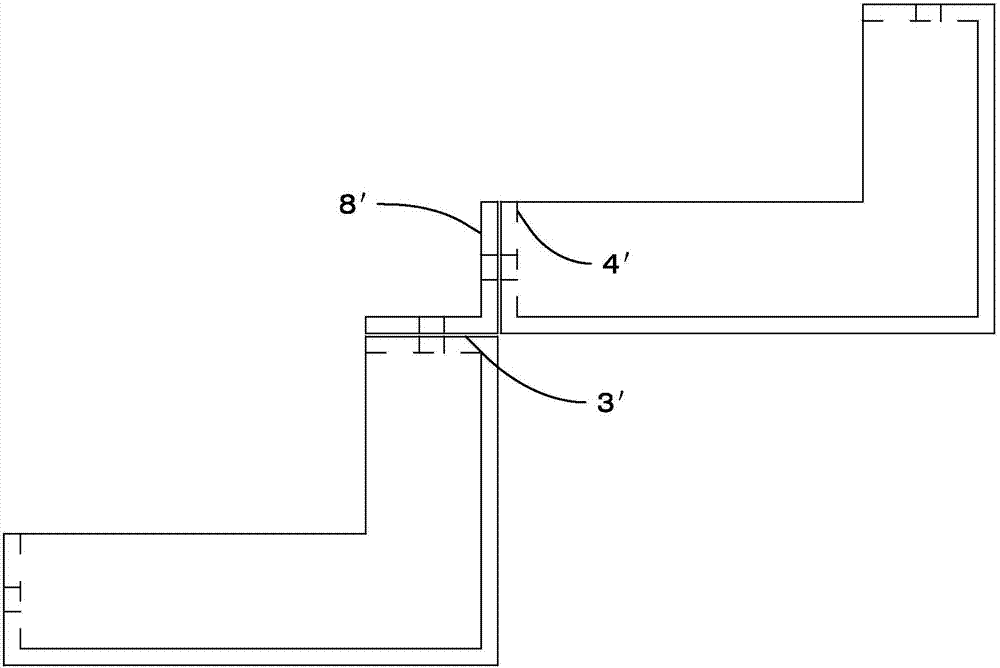

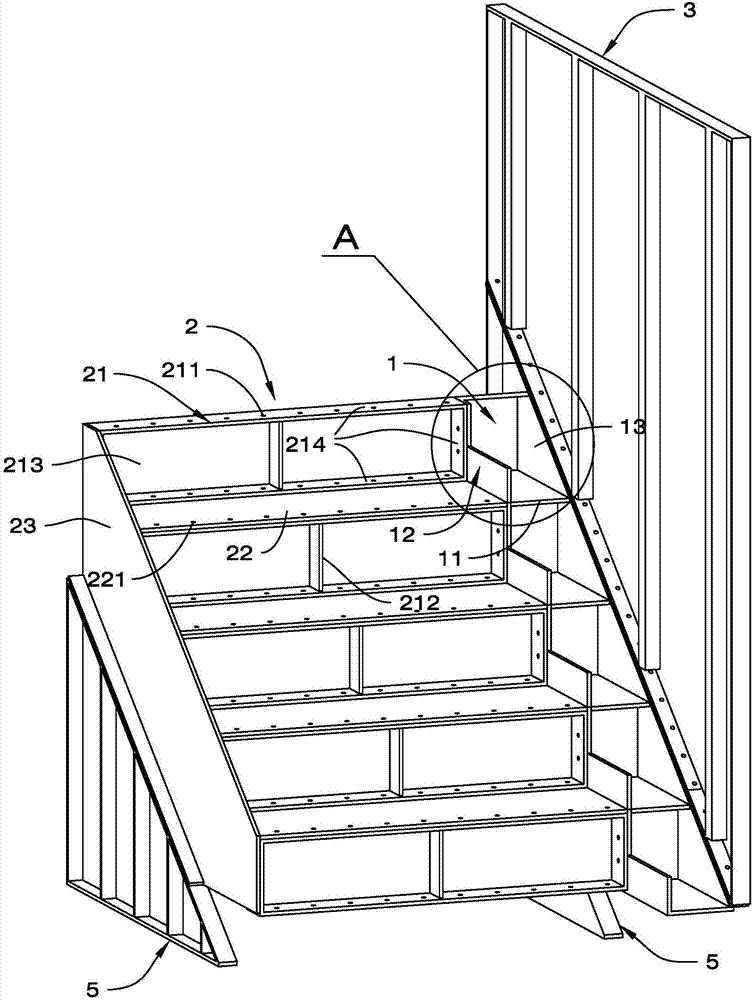

[0027] Such as Figure 3 to Figure 5 As shown, the stair connector of the present invention includes a stepped main body 1, and the left and right sides of each step of the stepped main body 1 are provided with side plates 12 and side plates 13 perpendicular to the horizontal step surface 11, and the side plates 12 Several pin holes A (not shown in the figure) are arranged on the top, and a connecting plate 14 perpendicular to the side plate 13 and extending along the inclined direction of the stepped main body 1 is fixed on the side plate 13, and a pin is provided on the connecting plate 14. Hole B (not shown in the figure). Specifically, the side plate 12 includes a vertical rectangular plate 121 and a horizontal rectangular plate 122. The vertical rectangular plate 121 is as high as the back plate 15 of the step and two adjacent right-angled sides are respectively fixed on the step surface 11 and the back plate 15. , the horizontal rectangular plate 122 is coplanar with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com