Elevation type tail water overhauling platform and manufacturing method and application thereof

A maintenance platform and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, hydroelectric power generation, etc., can solve problems such as irregular structure, high work risk, and difficult access to the maintenance position, so as to achieve convenient maintenance and maintenance, The effect of maintenance quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

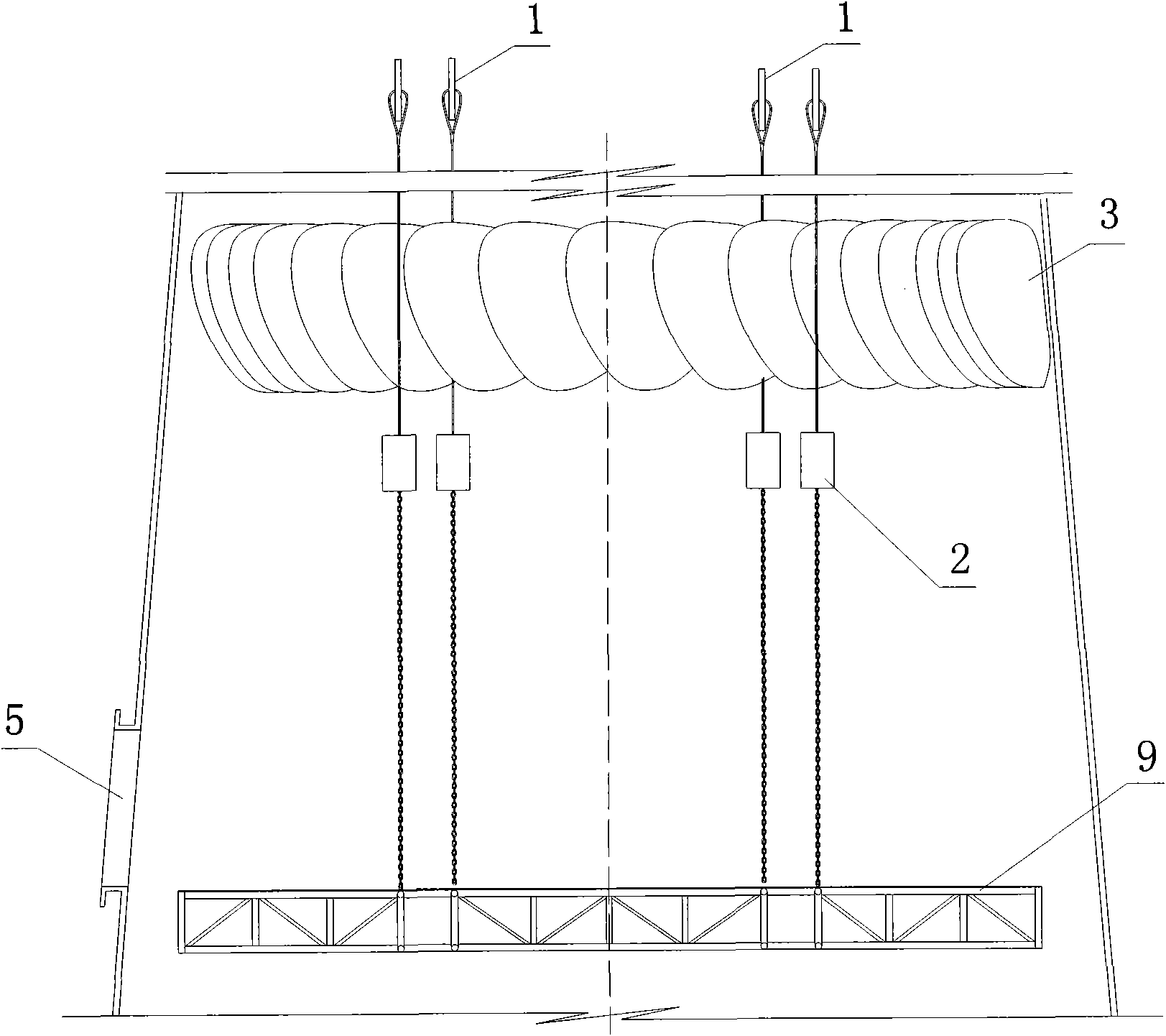

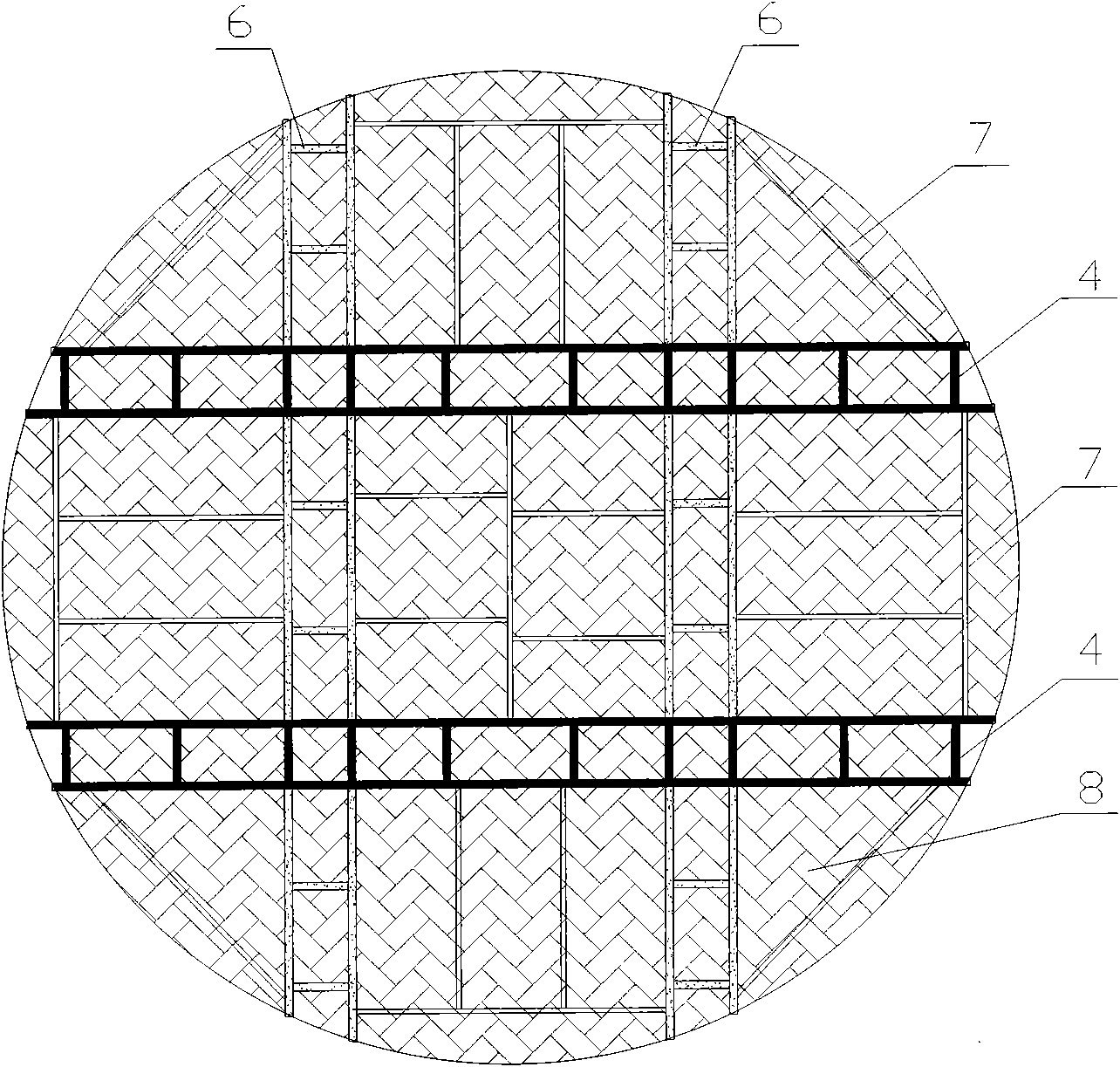

[0037] A lift-type tail water maintenance platform 9, the tail water maintenance platform 9 includes a lifting device 2, a platform main beam 4, a platform sub-beam 6, a support beam 7 and a platform plate 8, and the lifting device 2 is connected and fixed on the platform main beam On the beam 4, the platform sub-beam 6 is cross-fixed on the platform main beam 4, the support beam 7 is fixed on the platform main beam 4 and / or the platform sub-beam 6, and the two ends of the support beam 7 are respectively connected with The platform main beam 4 and / or the platform sub-beam 6 are connected and fixed, and the platform plate 8 is fixed on the platform main beam 4, the platform sub-beam 6 and the support beam 7; the lifting device 2 is provided with A fixed end, through which the steel wire rope is connected.

[0038] On the outside of the fixed guide vane, set 2 to 4 fixed suspension points 1 evenly divided according to the circumference, lock one end of the wire rope on the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com