Hand-cranking overhead line repairing and winding device

An overhead line and hand-operated technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of cumbersome operation procedures and reduce operation risks, and achieve the effects of shortening operation time, reducing operation risks, and simplifying procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

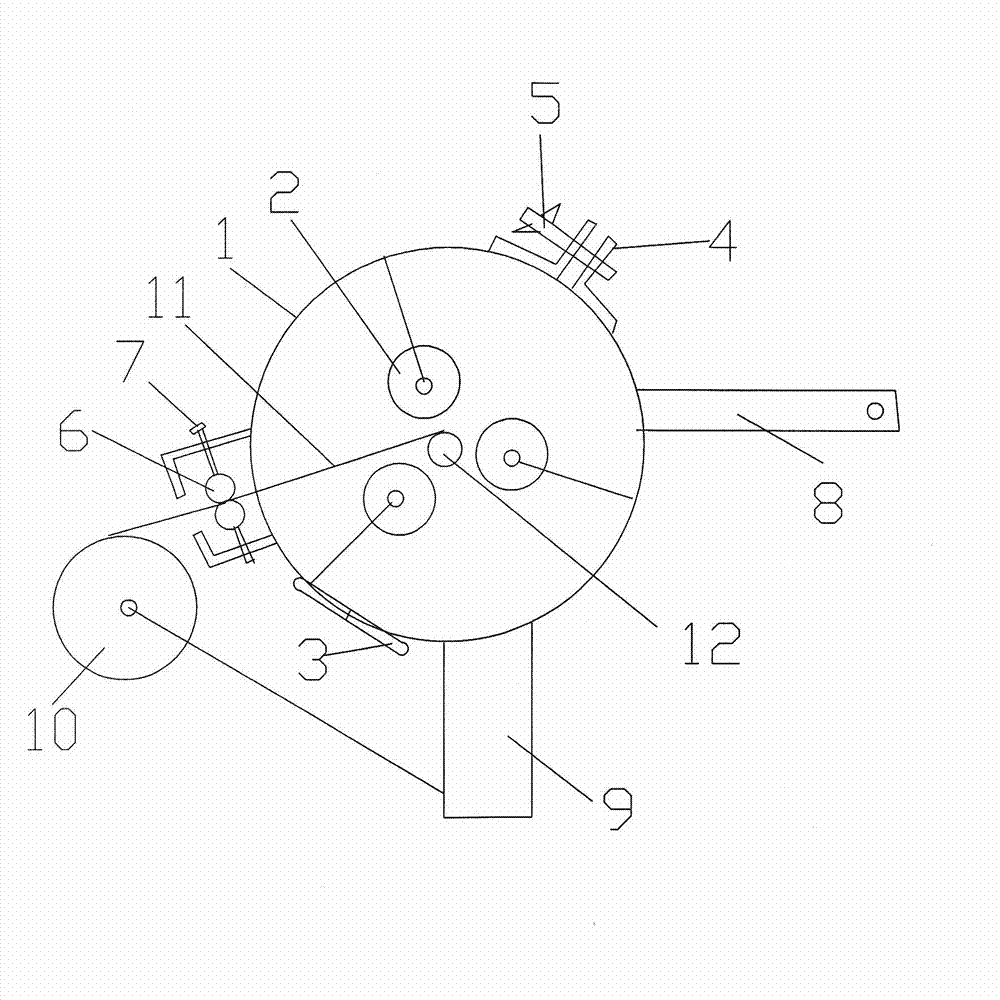

[0018] Such as figure 1 As shown, one side of the two semi-circular wheels forms a circular wheel 1 through a hinge 3, and the other side of the two semi-circular wheels is provided with a fixed clip 4, and the clip 4 is connected with an adjustable bolt 5; the circular wheel 1 is provided with three equilateral triangles. The hard rubber wheel 2, the outer surface of the hard rubber wheel 2 is provided with threads, and the outer side of the round wheel is provided with two top wheels 6, and the top wheel 6 is connected with an adjustable top wire 7 for adjusting the tightness; the outer side of the round wheel is provided with a rocker 8 and the wire-binding reel support 9, the wire-binding reel 10 is fixed on the wire-binding reel support 9, and the wire-binding 11 wound on the wire-binding reel 10 stretches out and is wound on the overhead wire 12 to be repaired by the top wheel 6.

[0019] The working principle of the present invention is that the aluminum alloy combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com