Maintenance method for coke oven door

A furnace door and coke oven technology, which is applied to coke ovens, coke oven doors/closures, and coke oven heating, etc., can solve problems such as low efficiency, ensure maintenance quality, facilitate alignment and restoration installation, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

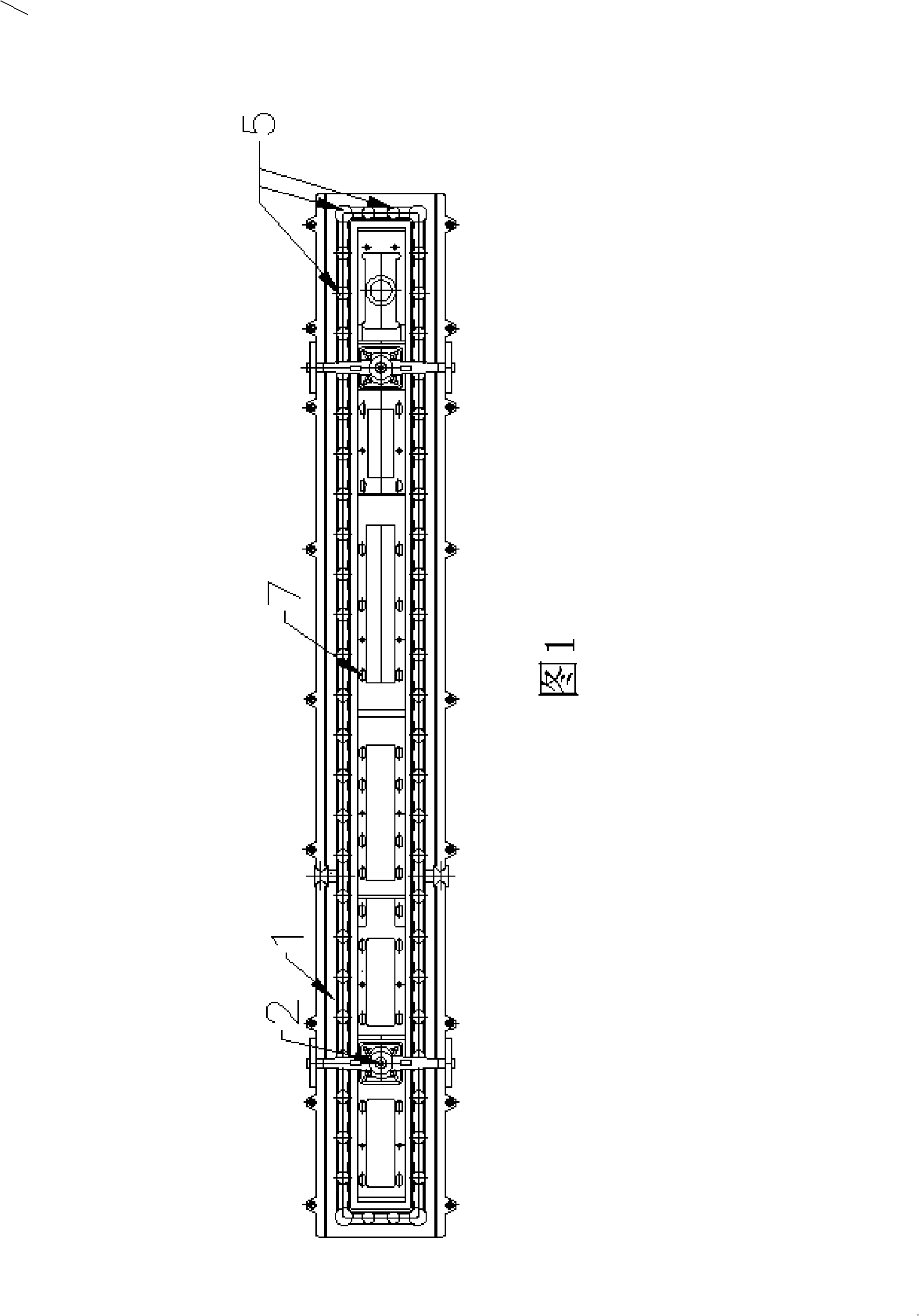

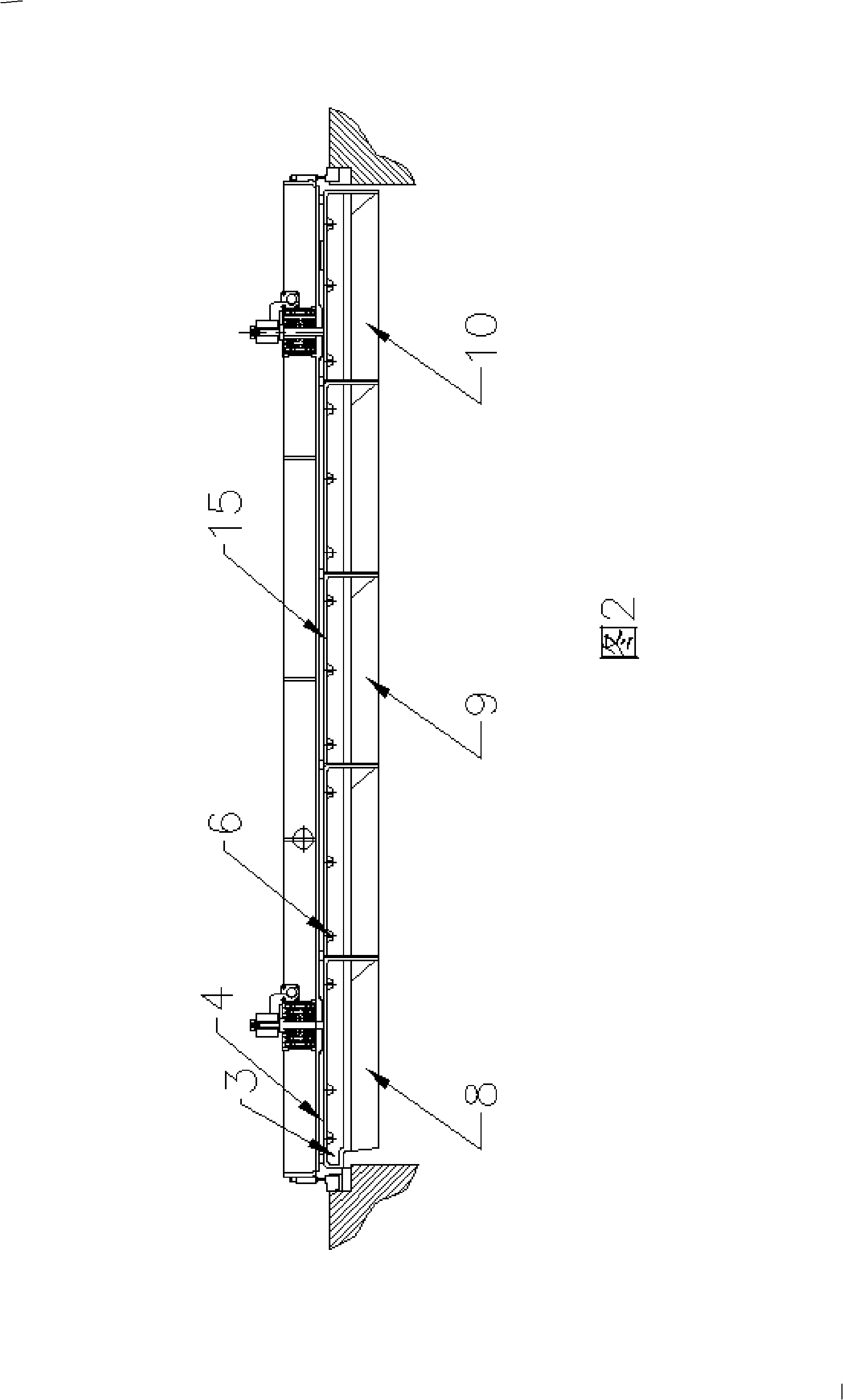

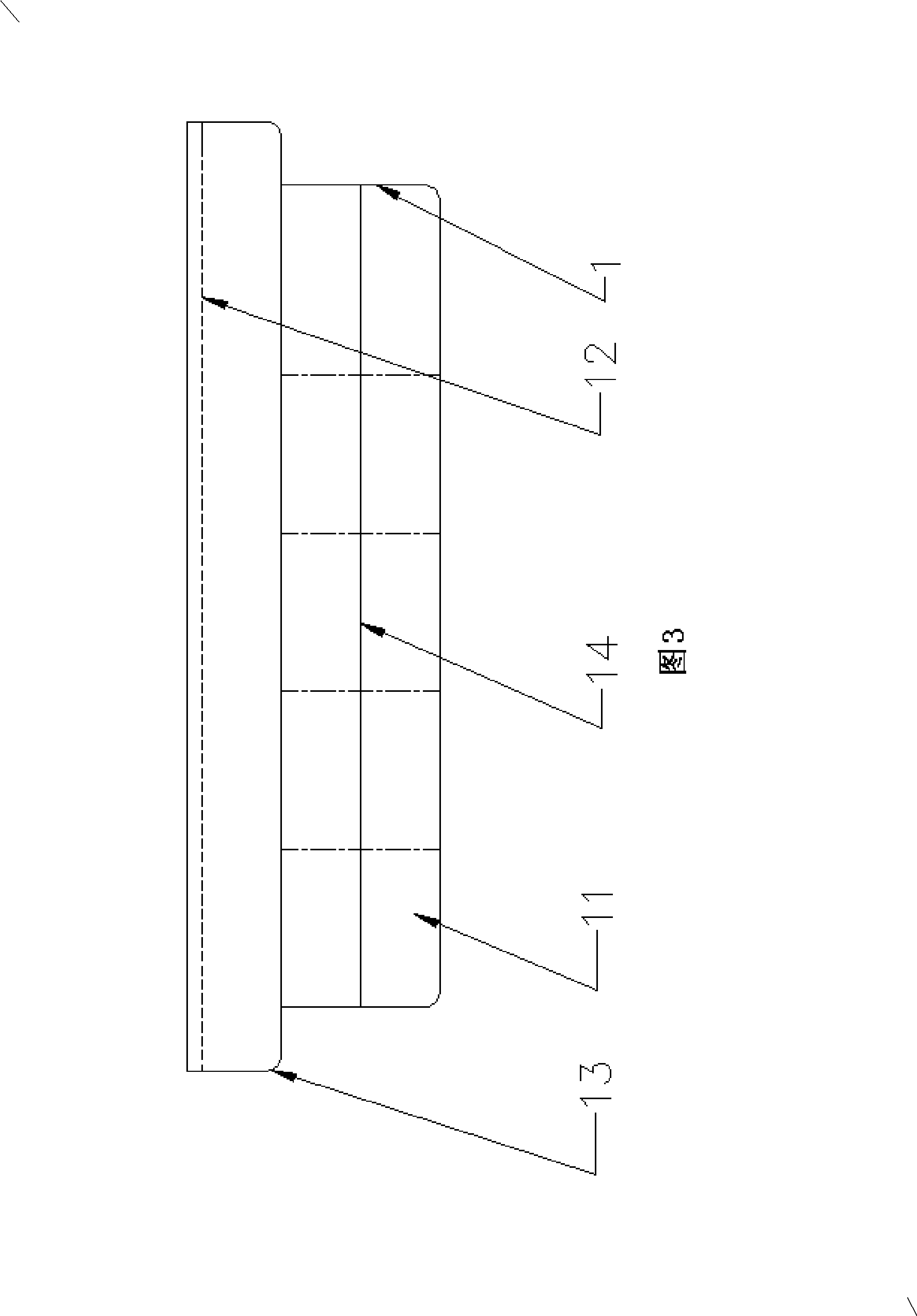

[0029] As shown in Fig. 1, Fig. 2 and Fig. 3, the coke oven door maintenance method of the present invention first pours out the furnace door to be overhauled and puts it on the maintenance frame, and after using the maintenance frame to rotate the furnace door by 180°, the furnace door Lift it out, and then turn the furnace door 90° for the convenience of subsequent operations, so that the furnace door lining brick is placed downward; use steel wire rope 14 and other temporary fixings to bind and connect the furnace door body 1 and brick groove 11, such as fixing with steel wire rope 14 It should be ensured that the steel wire rope 14 is prestressed so that there is no relative displacement between the furnace door body 1 and the brick groove 11; then the furnace door body connecting bolt 6 and the furnace door brick groove bolt 7 are loosened, and the furnace door reinforcement plate 15 and the knife edge are loosened. Hang out the web 12; after the damaged parts such as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com