Automatic recording system for concrete sample information

A concrete test piece and automatic recording technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of a large number of test pieces, difficulty in understanding the information of the test piece in real time, and reduced visibility, etc., to reduce labor intensity. , Guarantee the quality of maintenance and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

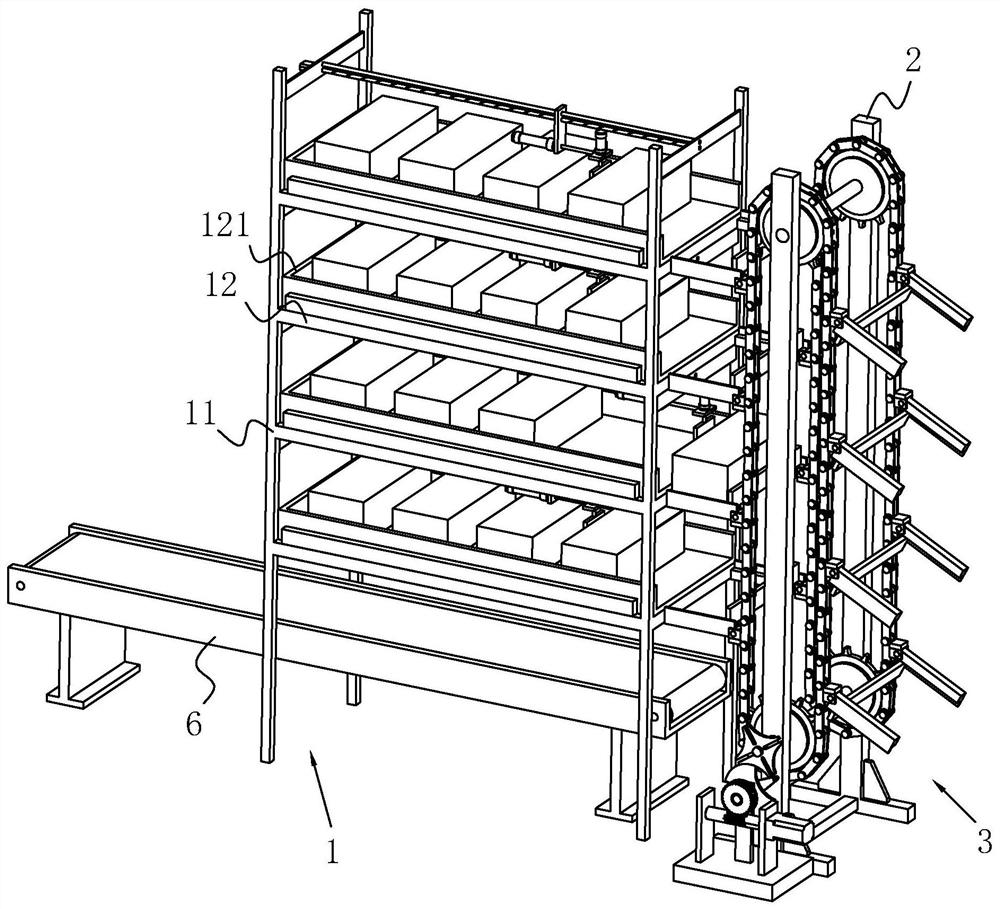

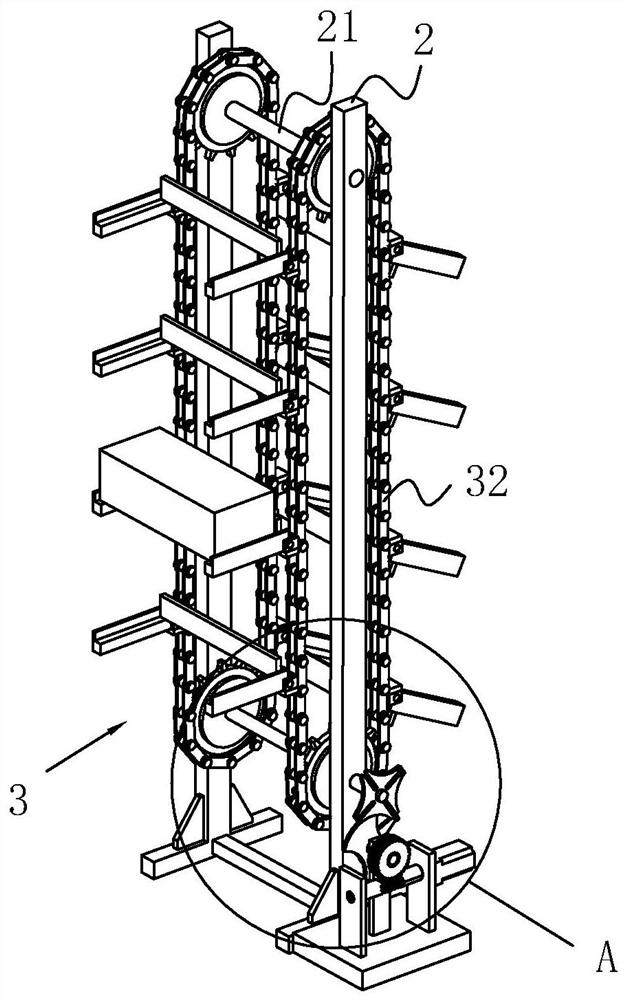

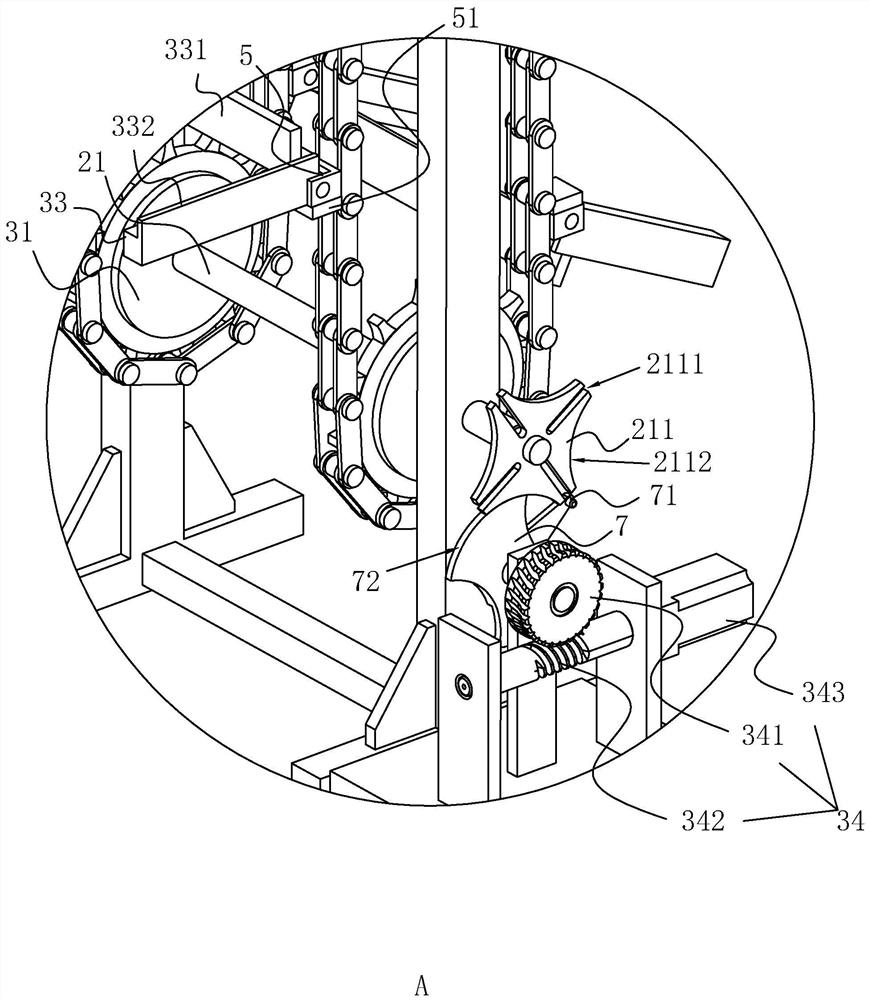

[0034] Such as figure 1 As shown, a concrete specimen information automatic recording system includes a shelf 1 and a curing box 121 for placing the specimen. The shelf 1 includes a column 11 and a beam 12 fixedly arranged on the column 11. The beam 12 is along the height of the column 11. Multiple direction intervals are set. The curing box 121 is arranged on the beam 12, and one end of the curing box 121 is opened, so as to facilitate the taking and placing of the test piece.

[0035] Such as figure 1 As shown, a sensing device (not shown in the figure) for sensing the curing information of the specimen is provided on the side wall of the curing box 121, and the sensing device includes a temperature sensor and a humidity sensor. The sensing device sends the information to the confidence processing center for processing, analysis and display, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com