Device for replacing blast furnace cooling walls without damaging furnace shells and replacing method thereof

A technology of cooling stave and blast furnace, applied in the direction of cooling device, etc., can solve the problems of increasing the damage of cooling stave, prolonging the maintenance time, increasing the maintenance cost, etc., to reduce the construction intensity, ensure the maintenance quality, and improve the maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

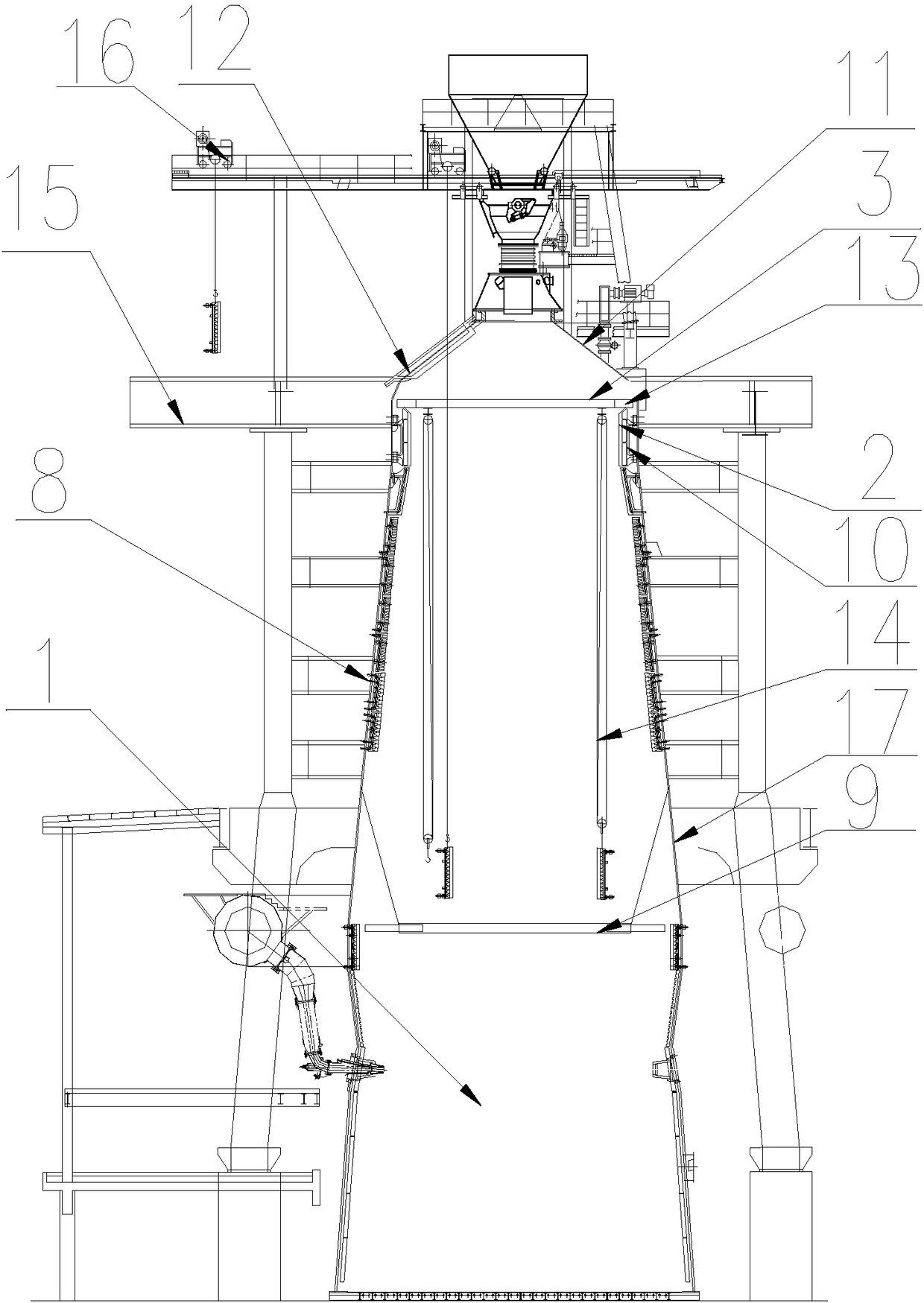

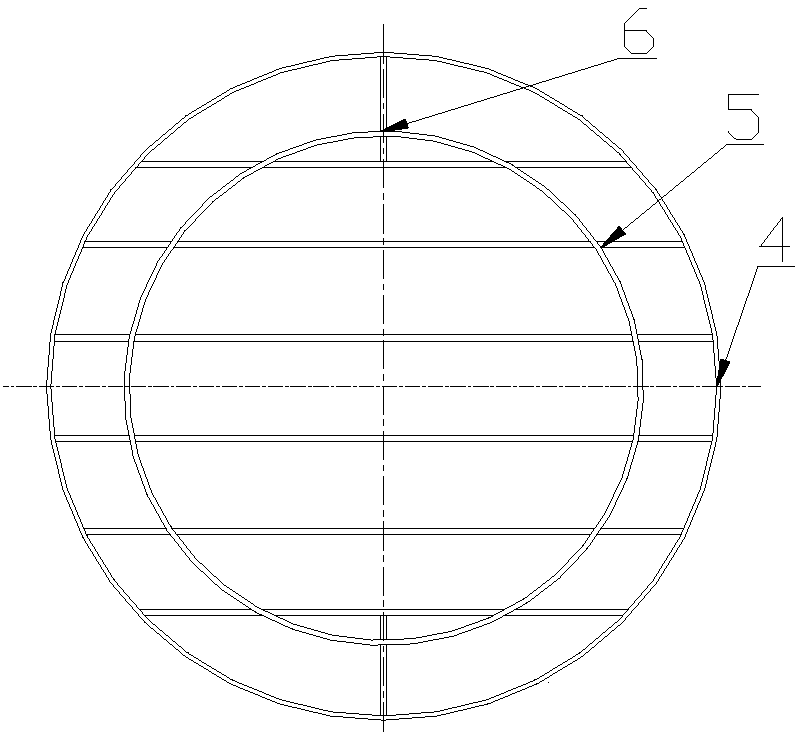

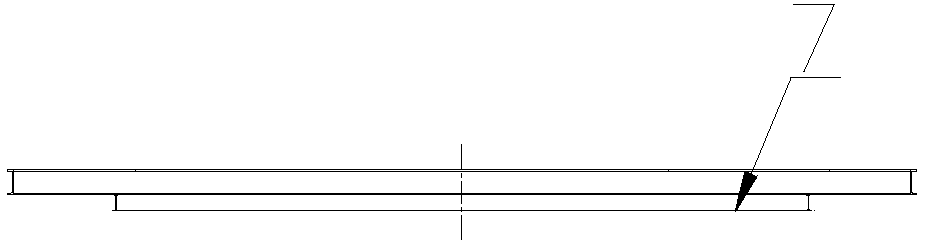

[0032] From figure 1 It can be seen that a device for replacing the stave of a blast furnace without destroying the furnace shell in this embodiment includes a hoisting ring beam 3, the outer ring of the hoisting ring beam 3 is provided with a temporary support 13, and the temporary support 13 is fixedly welded on the ring beam 4, the temporary supports 13 are arranged at equidistant intervals on the outer ring of the ring beam 4, the outer side of the temporary supports 13 is provided with a blast furnace body 1, the upper part of the blast furnace body 1 is provided with a furnace throat 10, and the inner wall of the furnace throat 10 is installed There are furnace throat steel bricks 2, and the upper surface of the furnace throat steel bricks 2 is provided with a hoisting ring beam 3, from Figure 2-3 It can be seen that the hoisting ring beam 3 is composed of the ring beam 4, the cross beam 5, the longitudinal beam 6 and the bottom ring beam 7, the ring beam 4, the cross b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com