Concrete maintenance device

A concrete and plastic film bag technology, applied in the field of concrete manufacturing, can solve the problems of high labor intensity, large water consumption, short life, etc., and achieve the effects of guaranteed maintenance quality, convenient operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

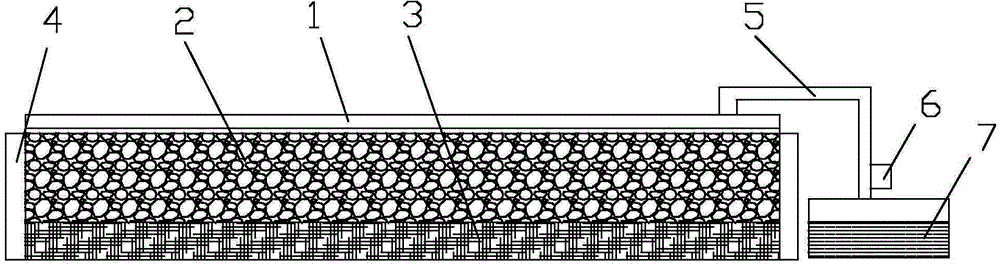

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a concrete maintenance device includes a water collection layer 1, a sponge layer 2, and a linen layer 3. The water collection layer is a plastic film bag, and the water collection layer has the strongest water storage capacity. The sponge layer is sequential, and the linen layer can For cement moisturizing and heat preservation, the plastic film can prevent the moisture of the sponge layer from evaporating, and the bottom of the plastic film bag has a water-permeable hole, and the plastic film bag is placed above the sponge layer, and the sponge layer is placed on the linen layer Above, the water-collecting layer, the sponge layer, and the linen layer are surrounded by a limiting plate 4 to surround the limiting groove, which can prevent the moisture of the sponge layer from fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com