Pre-twisted wire installation clamp

A technology of pre-twisted wire and clamp, applied in the direction of overhead line/cable equipment, etc., can solve the problems of uneven winding of pre-twisted wire and grommet, low maintenance work efficiency, not tight and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

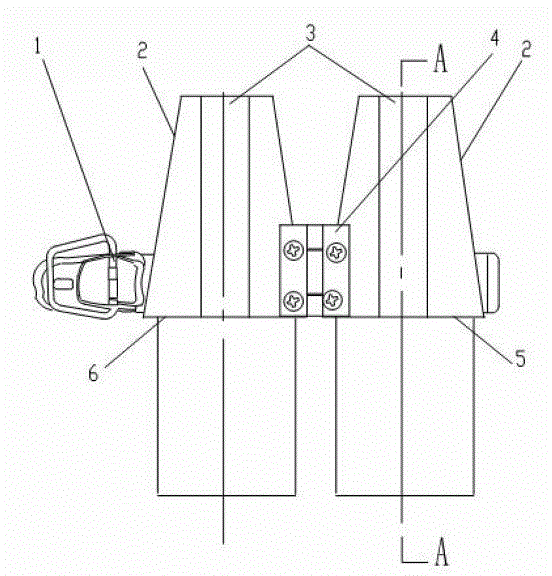

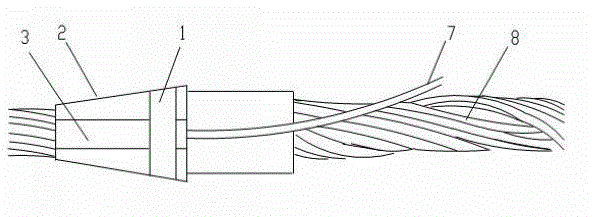

[0013] Embodiment 1. A pre-twisted wire installation jig is characterized in that: it comprises a split-type left shell 6 and a right shell 5; the left shell 6 and the right shell 5 are docked to form a sleeve by a locking mechanism, The central hole of the sleeve is a round hole; the outer surface of the sleeve is provided with a pre-twisted wire 7 fixing mechanism. The open-close left shell 6 and the right shell 5 and the locking mechanism are as follows: a hinge joint 4 is provided between the left shell 6 and the right shell 5, and the left shell 6 is provided on the sleeve. The buckle 1 docked with the right shell 5. How to use: Connect the left shell 6 and the right shell 5 to form a sleeve, and put it on the transmission wire 8 . The locking mechanism of the left shell 6 and the right shell 5 is butted with the buckle 1 through the hinge joint 4 . The locking mechanism can also use belts or pipe clamps to connect the left shell 6 and the right shell 5. The fixing mech...

Embodiment 2

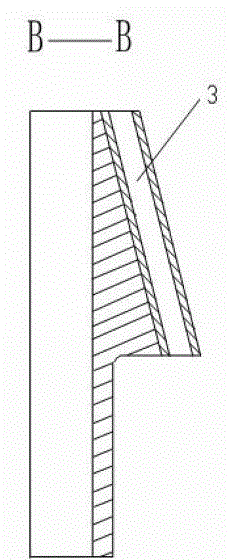

[0014] Embodiment 2: A pre-twisted wire installation jig is characterized in that it includes an openable left shell 6 and a right shell 5; the left shell 6 and the right shell 5 are butted to form a sleeve through a locking mechanism, The central hole of the sleeve is a round hole; the outer surface of the sleeve is provided with a pre-twisted wire 7 fixing mechanism. The outer surface of the upper part of the sleeve is a conical surface 2 . The fixing mechanism of the pre-twisted wire 7 is a casing 3, and there are two casings 3 fixed on the left casing 6 and the right casing 5 respectively. How to use: connect the left shell 6 and the right shell 5 through a locking mechanism to form a sleeve, and put it on the power transmission wire 8. The locking mechanism can be a belt or a pipe collar. The pre-twisted wire 7 fixing mechanism can be a casing, and the end of the pre-twisted wire 7 is inserted into the casing to fix it, so that the pre-twisted wire 7 is wound and repaire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com