Water turbine guide vane thrust gap adjusting structure

A gap adjustment and water turbine technology, applied in the fields of hydropower, mechanical equipment, machines/engines, etc., can solve the problems of time-consuming and manpower, and achieve the effect of ensuring the quality of maintenance, saving time and manpower, and shortening the maintenance period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

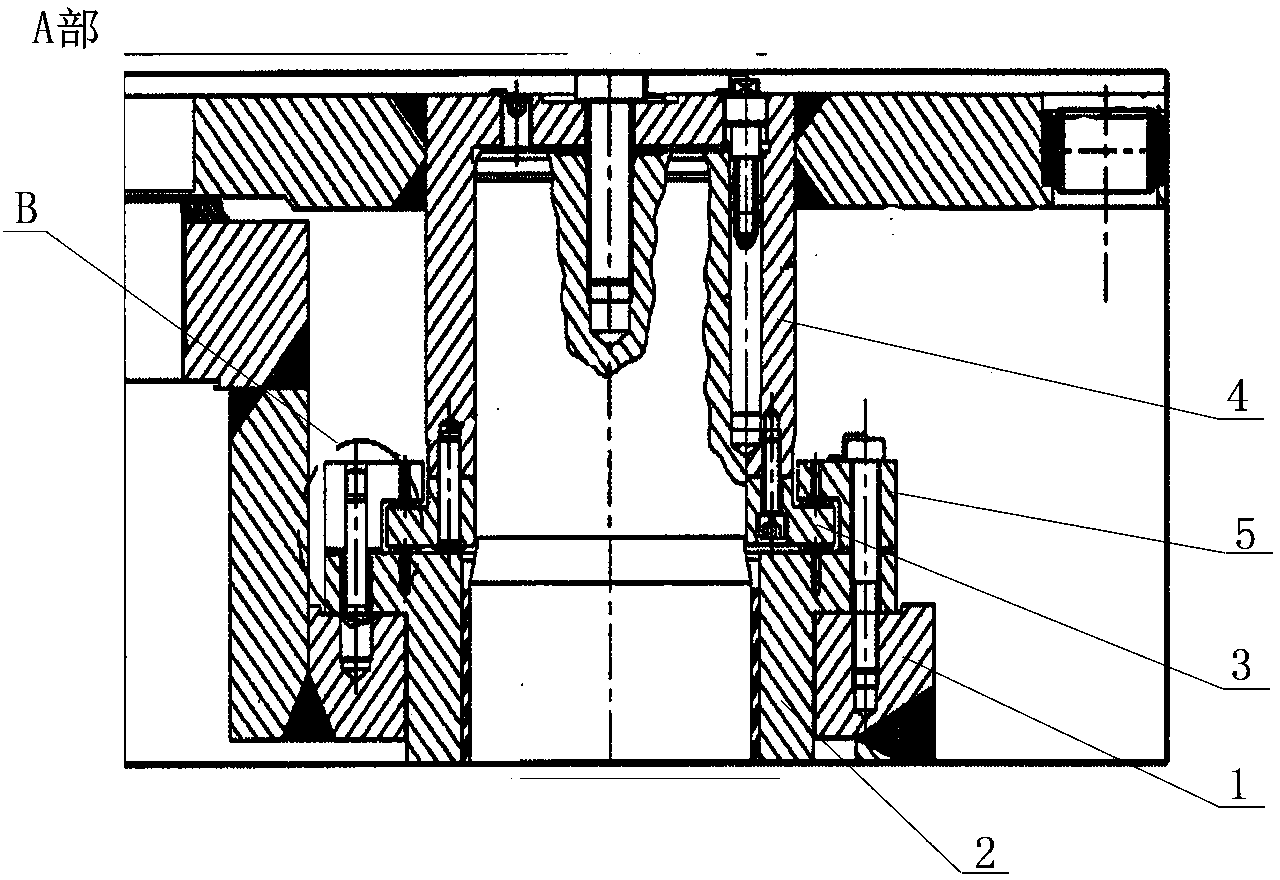

[0013] Embodiment 1: A structure for adjusting the thrust gap of the guide vane of a water turbine, participated in figure 1 and figure 2 A guide vane sleeve 2 is fixedly installed on the inner side and upper side of the center hole of the top cover 1, and an L-shaped movable guide vane 3 is fixedly connected to the lower end of the tubular guide vane crank arm 4; the L-shaped guide vane thrust ring 5 is reversed On the upper side of the L-shaped movable guide vane 3 , and the L-shaped guide vane thrust ring 3 is fixed on the upper side of the guide vane sleeve 2 and the top cover 1 .

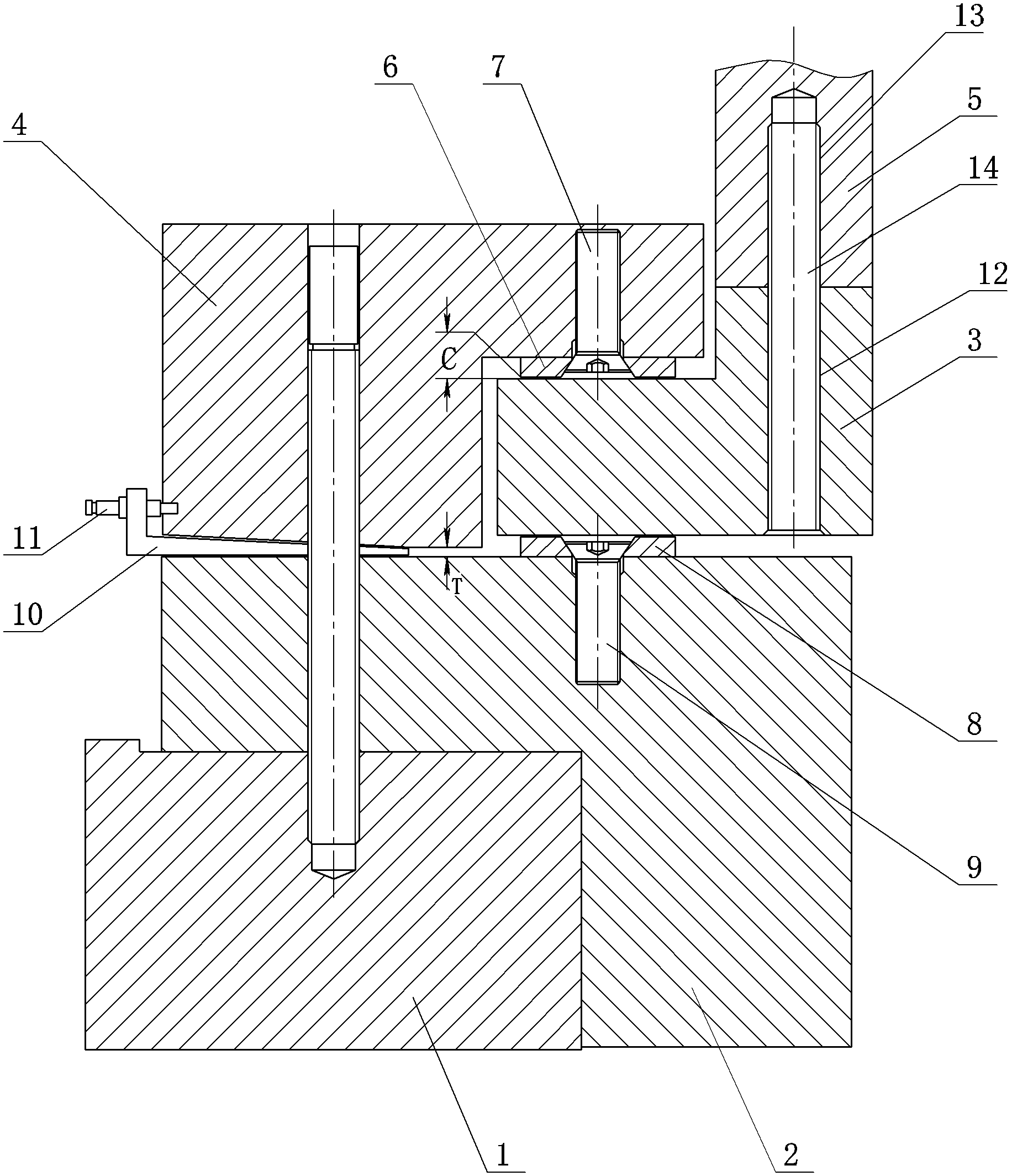

[0014] see image 3 , an upper gasket 6 is placed between the upper end surface of the turned-out edge of the L-shaped movable guide vane 3 and the lower end surface of the L-shaped guide vane thrust ring 5; A lower gasket 8 is placed between the upper end surfaces of the leaf sleeve 2, as shown in the thrust gap C in the figure. The upper gasket 6 and the lower gasket 8 are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com