Non- pneumatic tire

A tire and tread technology, applied to non-pneumatic tires, tire parts, vehicle parts, etc., can solve problems such as different tires and difficult tire production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

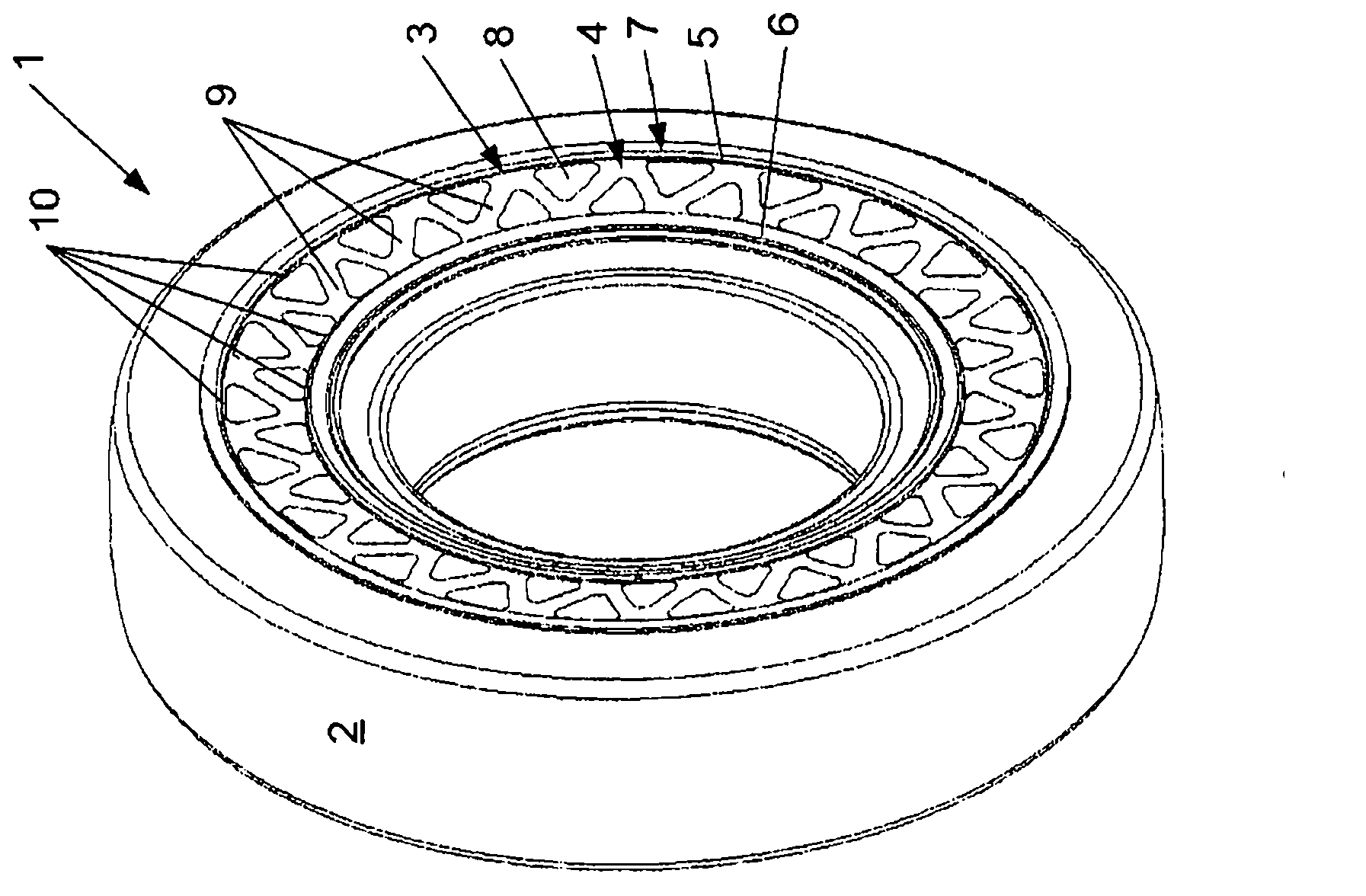

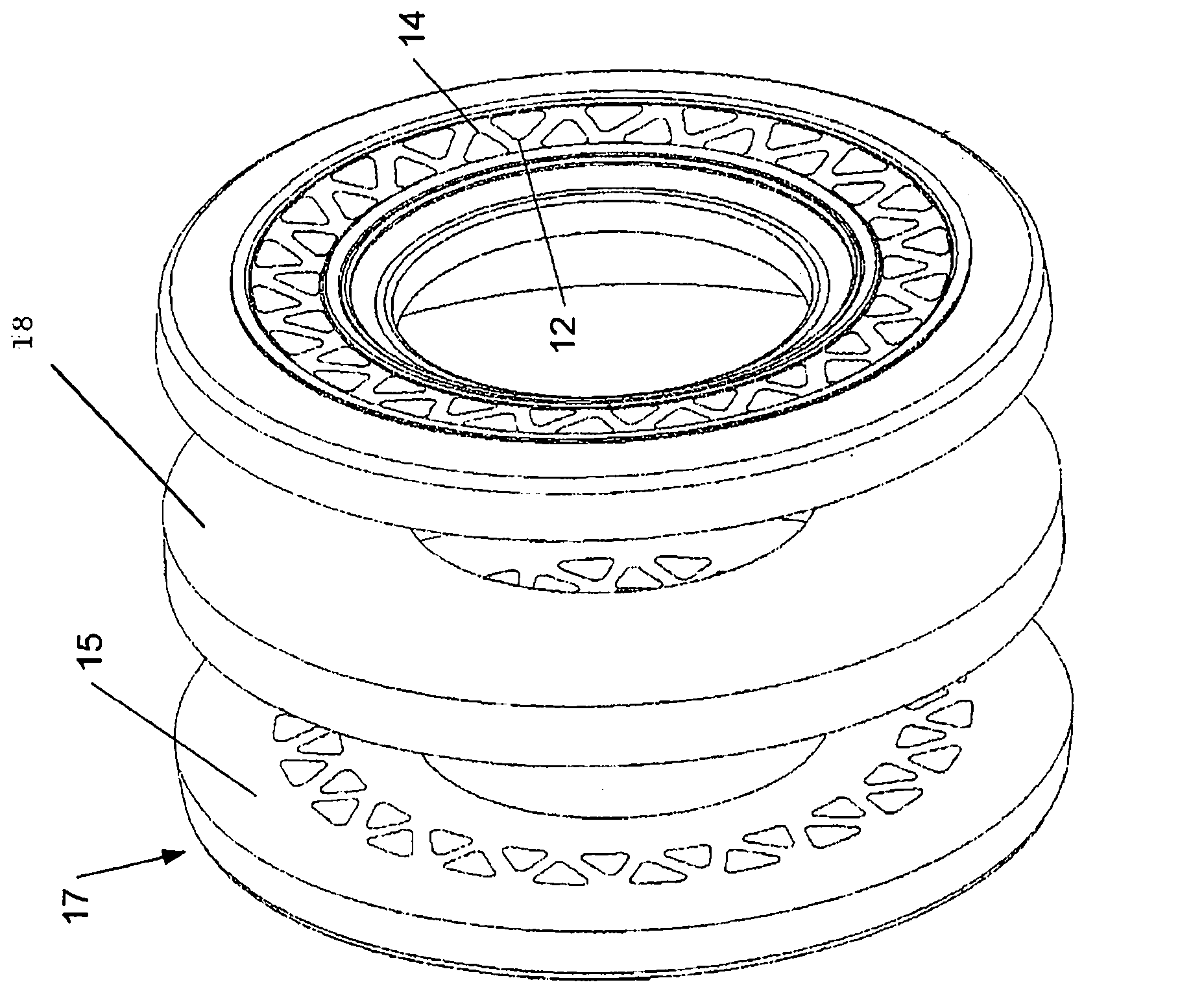

[0058] Figure 1a A tire 1 is shown comprising a rubber tread portion 2 extending in the circumferential direction of the tire 1 for contacting the ground. The tread portion 2 is preferably provided with a tread pattern having protrusions 13, such as Figure 5 shown. The specific design of the tread portion 2 is however not critical to the invention and can also be determined by a person skilled in the art. The tread pattern may, for example, be specifically configured for running in wet and / or dry conditions, etc., or may be specifically configured for the specific ground on which it will be used.

[0059] The tire 1 may be configured to be mounted on any known type of vehicle, such as for example but not limited to cars, trucks, and the like.

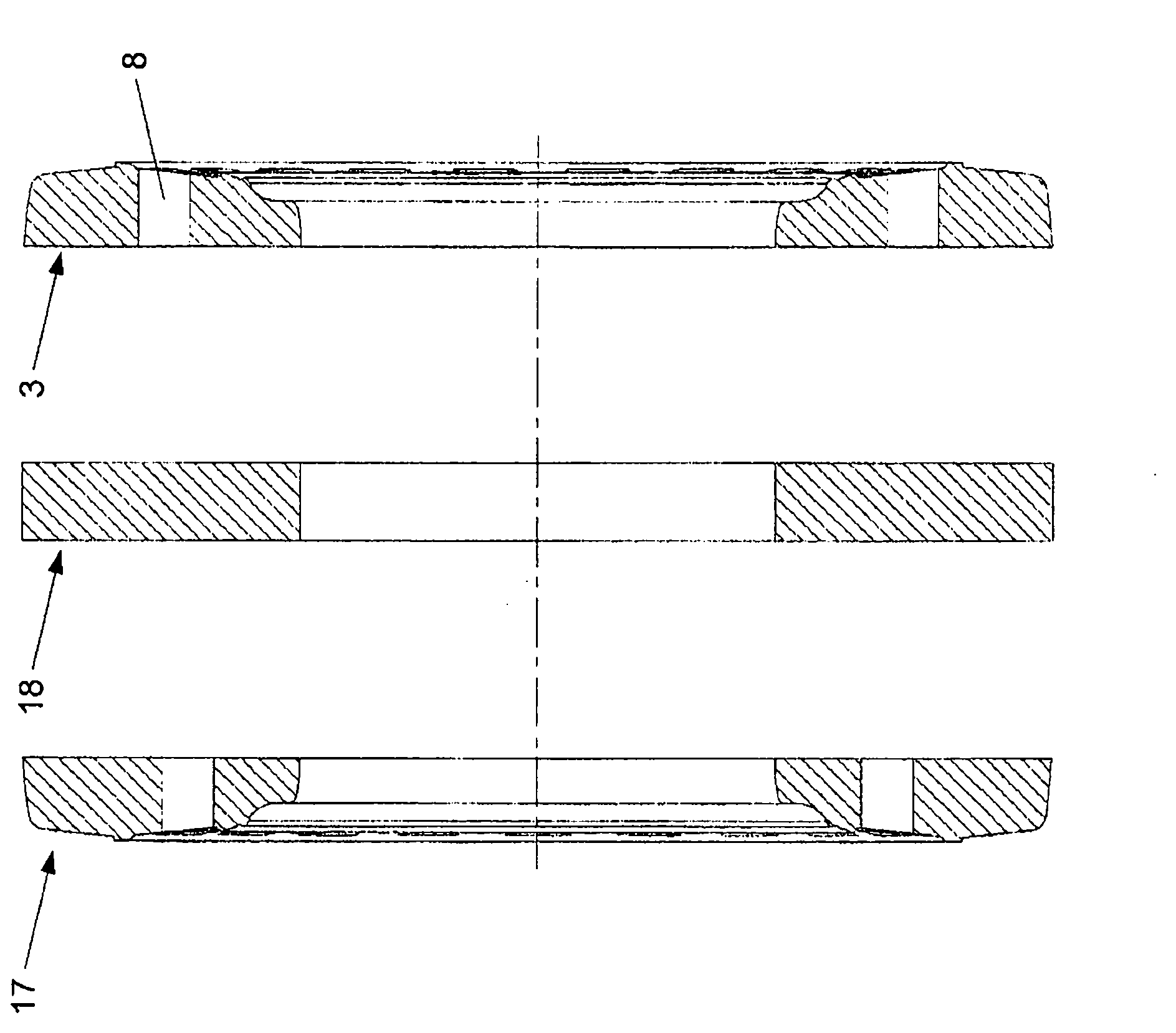

[0060] The tire 1 also includes a frame ring 3 . The carcass ring 3 contacts the tread portion 2 and extends therealong so as to support the vehicle on the tread portion 2 . The frame ring 3 is produced from frame parts 4 . The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com