Long-span assembly type road steel truss bridge

A prefabricated, long-span technology, applied in the direction of truss bridges, bridges, bridge forms, etc., can solve problems such as poor traffic, affecting festival traffic, and bridge equipment that cannot meet the requirements, so as to solve the problem of small span, reduced deflection, and enhanced The effect of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

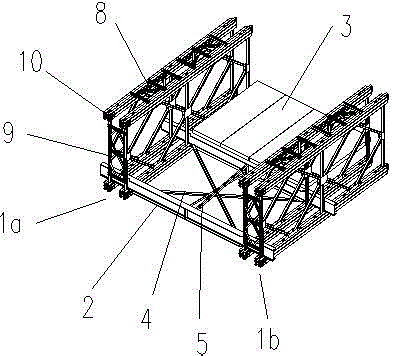

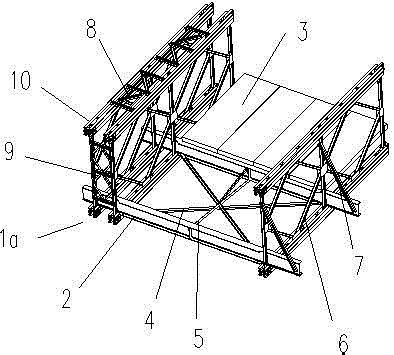

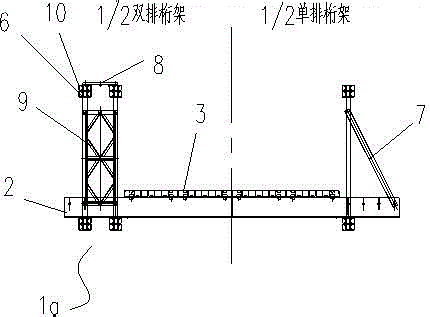

[0018] The present invention will be further explained below in conjunction with the drawings:

[0019] Such as figure 1 , 2 As shown in Figure 3, a large-span assembled highway steel truss bridge includes a left truss (1a) and a right truss (1b), and a cross beam (2) is arranged between the left truss (1a) and the right truss (1b) , A bridge deck (3) is provided on the cross beam (2), and a wind resistance rod (4) and a vertical wind structure (5) are provided between two adjacent beams (2); the left truss (1a) Both the right truss (1b) and the right truss (1b) can be single-row truss or multiple-row trusses. If the main truss is a single-row truss, the truss (6) and the beam (2) are connected by diagonal braces (7); if the main truss is multiple rows The truss, the truss (6) and the beam (2) are connected by a horizontal support frame (8) and a vertical support frame (9). The upper and lower chords of the truss (6) are provided with reinforced chords (10).

[0020] Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com