Pitching type truss bridge manufacturing method

A manufacturing method and technology of a truss bridge, which are applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of difficult manufacturing process and difficult manufacturing method, and achieve the effect of reducing manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited by this.

[0036] The manufacturing method of the pitch truss bridge according to the present embodiment includes the following steps:

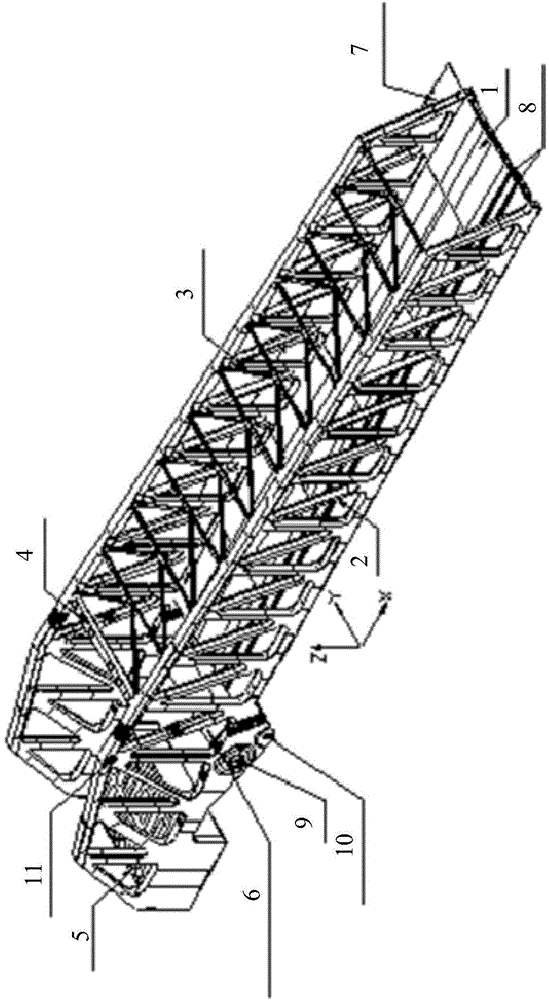

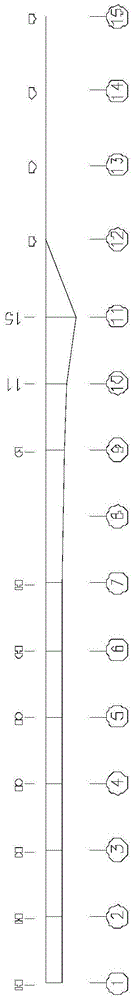

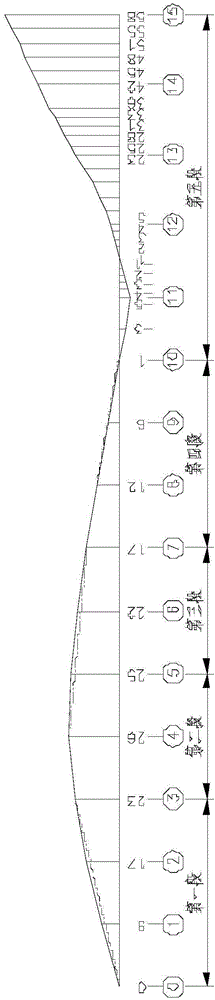

[0037] According to the Z-direction camber requirement of the pitching truss bridge, the truss side piece is divided into a plurality of truss segments, and each truss segment is linear;

[0038] The plurality of truss segments are respectively made, and the closing margin of each truss segment is cut according to the Z-direction camber requirement;

[0039] The bridge deck is divided into a plurality of bridge deck segments to be produced separately;

[0040] The plurality of truss segments and the plurality of bridge deck segments are sequentially assembled together.

[0041] The following describes in detail with reference to the accompanying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com