Method for controlling changes in three-truss height difference of combined highway and railway bridge for structural system

A road-rail dual-purpose bridge and a control method technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of lack of very mature technical means, increase of main truss support reaction force, and excessive stress on main girder nodes. Large and other problems, to achieve the effect of preventing the height difference of the three trusses from being too large, preventing local stress concentration, and controlling the change of internal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

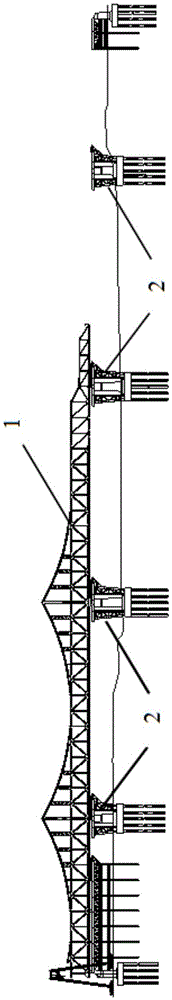

[0025] Referring to the accompanying drawings, the method for controlling the structural system of the three-girder height difference of the road-rail dual-purpose bridge includes the following construction steps:

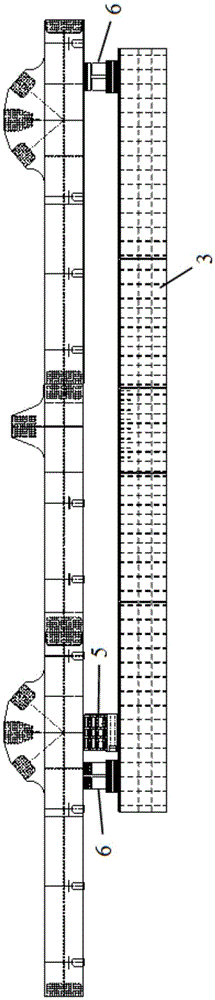

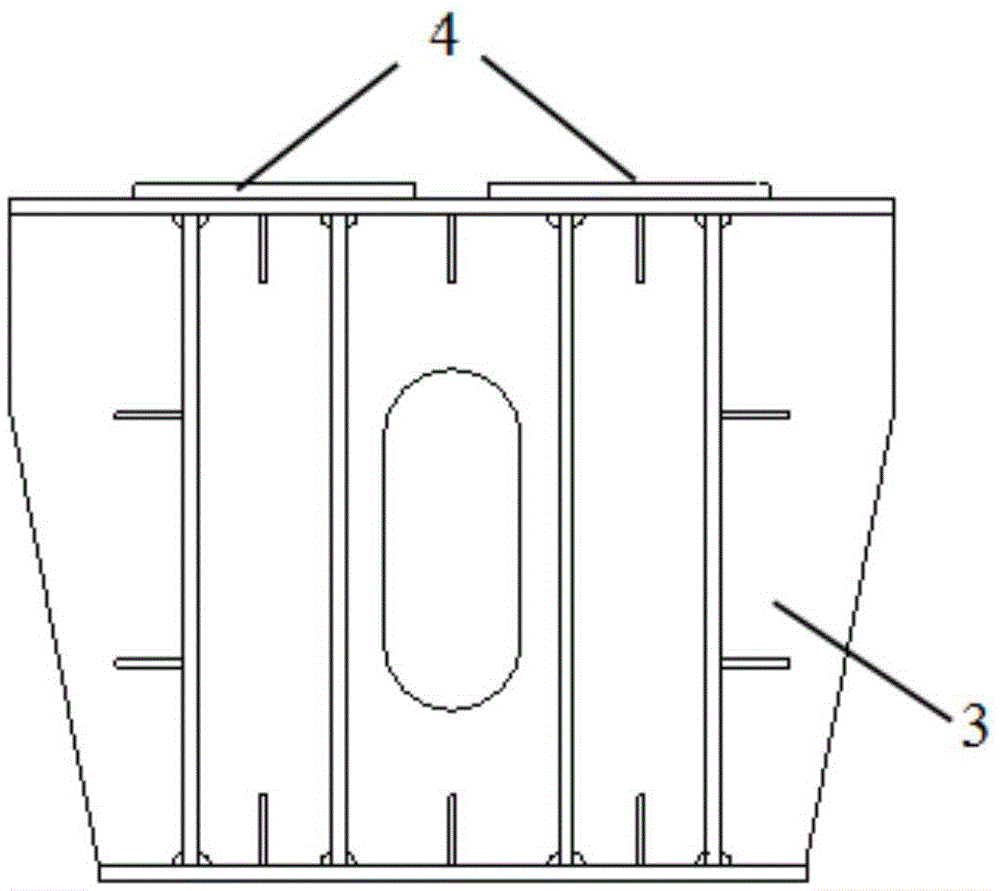

[0026] Complete the erection of brackets 2 next to each main pier in the early stage of construction, check the elevation of the pre-embedded plate at the top of the pier and the top plate of bracket columns with a level gauge, control the height difference of the support of the slideway beam 3, and then complete the hoisting of the three-truss slideway beam 3 in sequence , both ends of the slideway beam 3 are connected to the top of the bracket column, and the middle part is connected to the embedded plate of the pier top, and the section of the slideway beam changes within the range of the pier top. During the hoisting process, the elevation of the top of the slideway beam 3 is monitored to strictly control the slide The vertical height difference of the single gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com