Double-deck bridge floor combined trussed girder bridge

A technology for truss bridges and bridge decks, applied in the field of new bridge structures, can solve problems such as unfavorable steel bearing capacity and inability to meet the needs of traffic development, and achieve the effects of strong traffic capacity, simple structure, and high driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

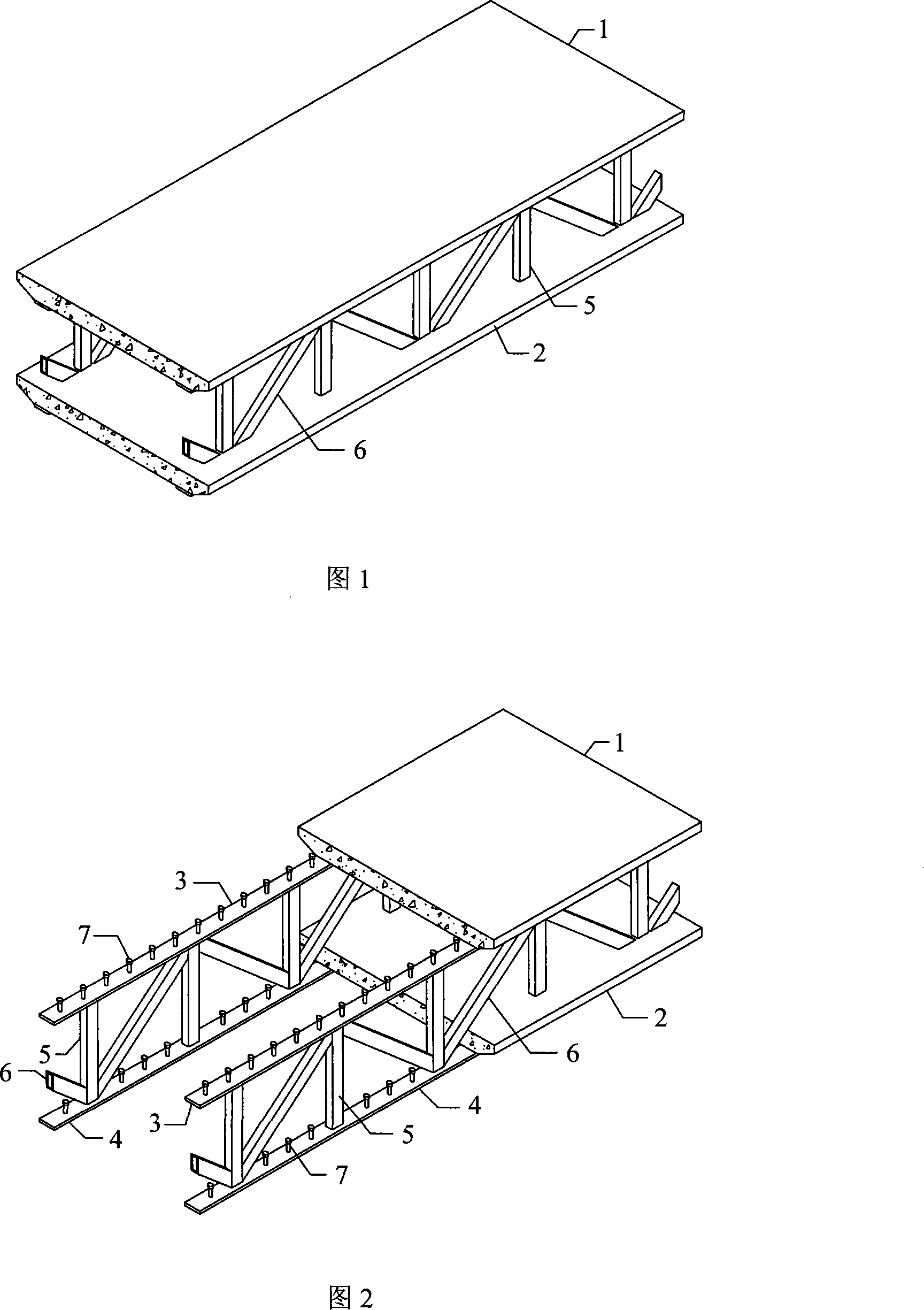

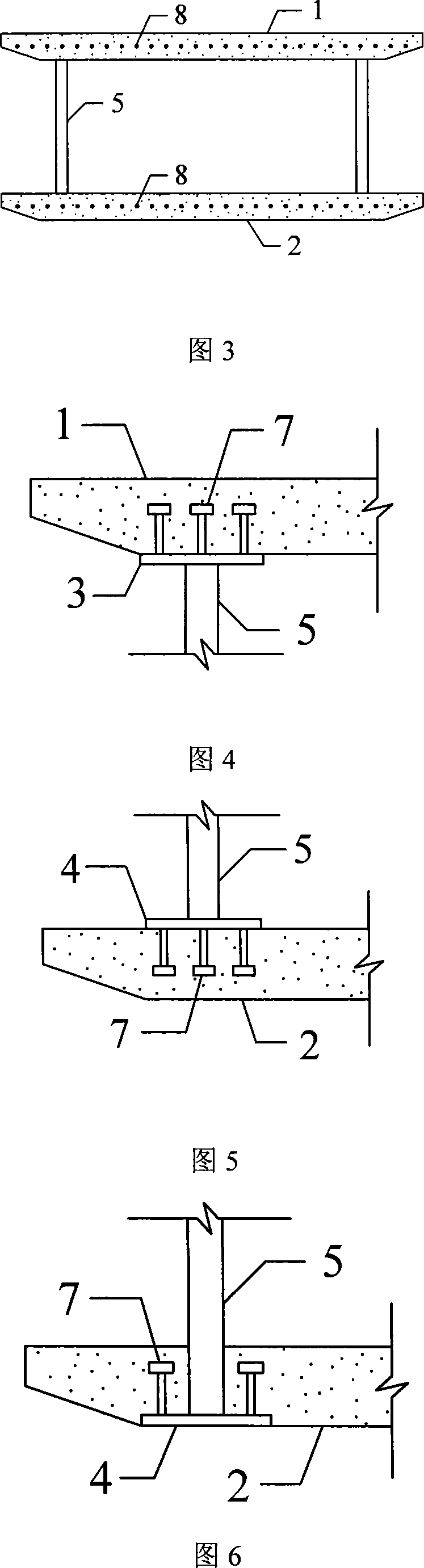

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The double-deck composite truss bridge provided by the present invention is composed of an upper concrete bridge deck 1, a lower concrete bridge deck 2 and a steel structure web, and is connected by an upper chord gusset 3, a lower chord gusset 4 and a shear connector 7. The parts are linked together into a whole. The upper and lower concrete bridge decks are used not only as bridge decks to bear vehicle loads, but also as the upper and lower chord parts of the truss girders to participate in the overall stress of the structure (as shown in Figures 1 and 2). The steel structure webs are composed of vertical webs 5 and diagonal webs 6, and concrete can also be poured into the vertical webs and diagonal webs to resist the shear force of the truss bridge. The upper concrete bridge deck 1 and the lower concrete bridge deck 2 in the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com