Wide span variable girder high continuous steel truss bridge cantilever erection mid-span closure construction method

A steel truss girder bridge and large-span technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of infeasible river channels, inability to set up lifting equipment, and stress buckling of rods required for navigation, and achieve large The effect of promoting value, reducing construction difficulty and risk, and reducing adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Referring to the accompanying drawings, a construction method for cantilever erection of a large-span variable truss-height continuous steel truss girder bridge, including the following construction steps:

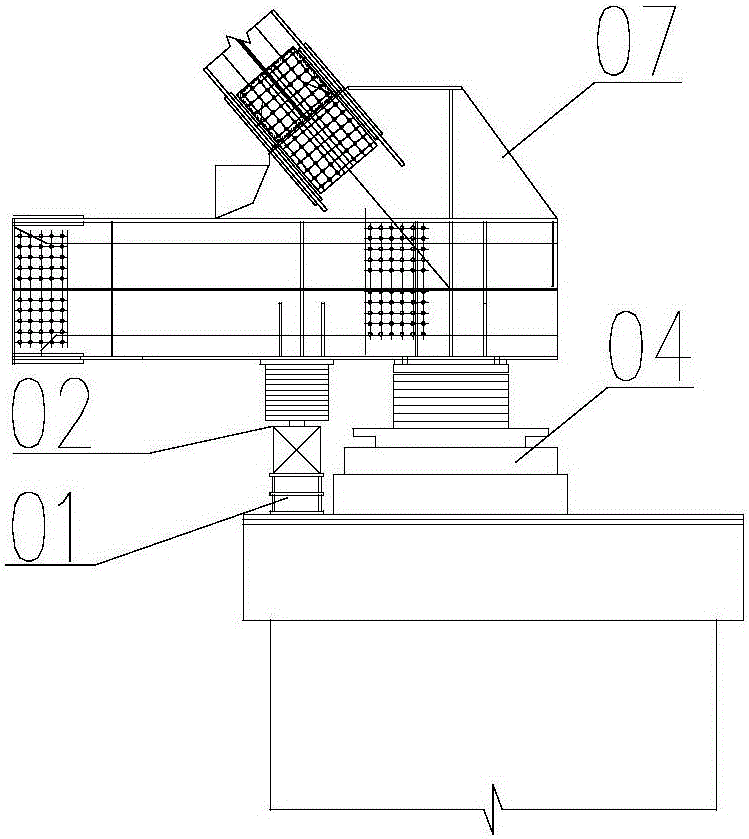

[0040] 1) The side-span steel girder is erected with temporary buttress auxiliary semi-cantilever, the main span is erected with full cantilever assembly, cantilevered from both sides to the mid-span and closed in the mid-span of the main span;

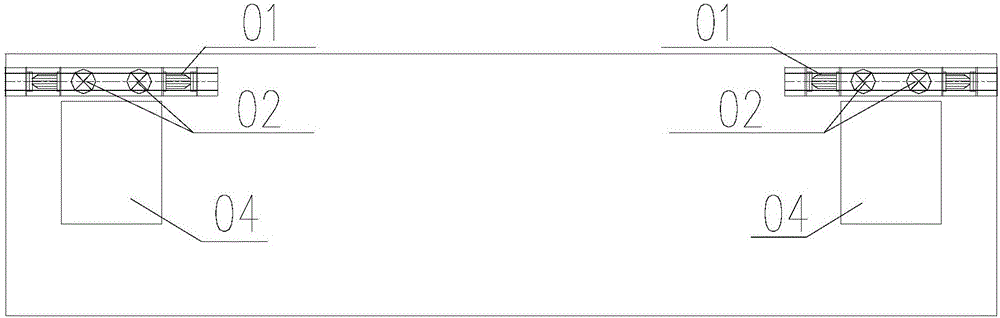

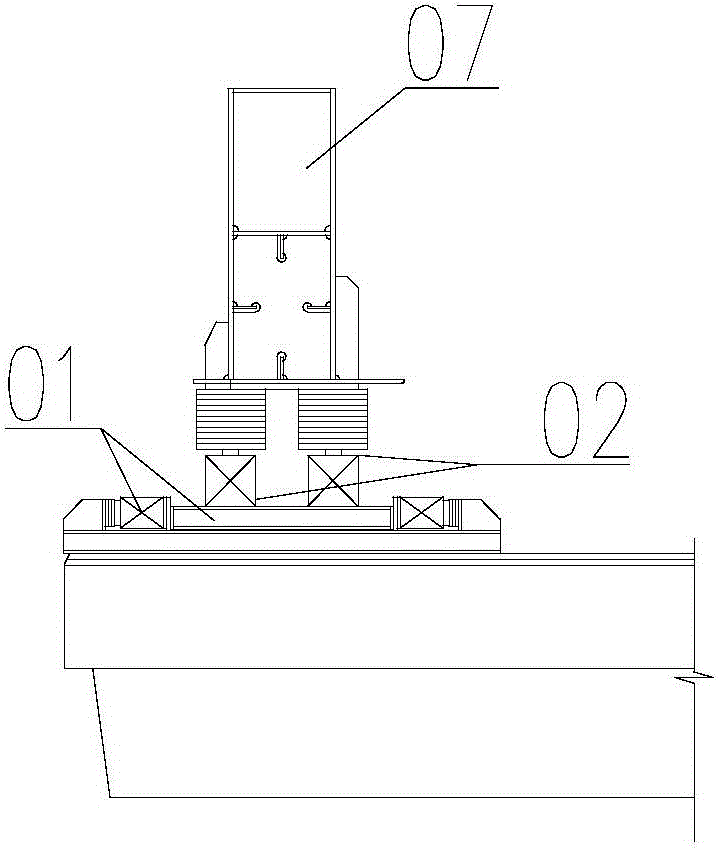

[0041] 2) First, vertical and horizontal deviation correction devices 01 and vertical jack devices 02 are respectively arranged on the top of each permanent pier to adjust the steel beam vertically, horizontally and vertically;

[0042] 3) Secondly, according to the result of the closing gap deviation calculated by the finite element software, after the steel girder cantilever is erected to the two sections of the main span, the side pier and the main pier jack system 02 are used to jack up the steel girder to the predetermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com