Steel pipe concrete combined truss bridge

A technology for steel tube concrete and truss bridges, applied in truss bridges, bridges, bridge forms, etc., can solve the problems of high strength requirements for connecting steel plates, small connection surfaces, and limited connection capacity, so as to increase pullout resistance and reduce stress , Enhance the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

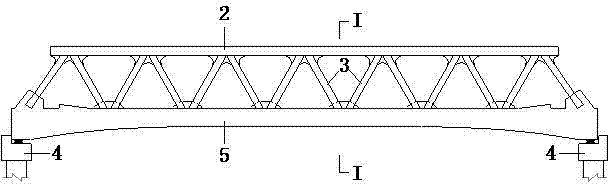

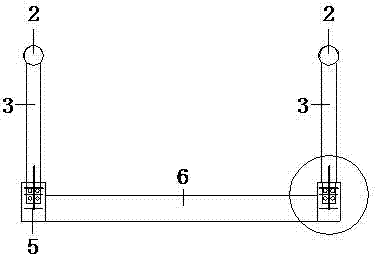

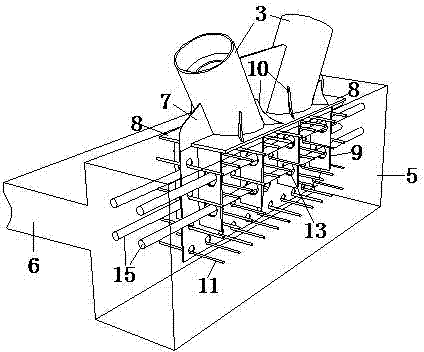

[0018] see figure 1 and figure 2 A steel tube concrete composite truss bridge includes piers 4 at both ends, a bridge deck 6, two parallel upper chords 2 and two parallel lower chords 5; The webs 3 are connected, and the evenly distributed webs 3 are connected sequentially in a W shape, that is, the lower end of one web corresponds to the lower end of the left adjacent web, and the upper end corresponds to the upper end of the right adjacent web; The root web 3 and the lower chord 5 are connected through the gusset plate 7 to form the lower chord node; see image 3 and Figure 4 , the middle of the upper part of the gusset plate 7 runs through two adjacent web members 3, the lower part is located at the lower chord 5, and the lower part of the gusset plate 7 is uniformly provided with reinforcement holes, and the reinforcement holes are provided with shear reinforcement bars 11, including two The longitudinal prestressed steel beam 15 of the lower chord above. At the node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com