Hydraulic supporting device of suspended top beams for roadways in shed

A hydraulic support and roadway technology, which is applied to the mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of too many single pillar drilling bottoms, difficulty in greatly increasing the speed of support and withdrawal, and a large number of users , to achieve the effect of maintaining the height and section of the roadway, high promotion and practical value, and convenient installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

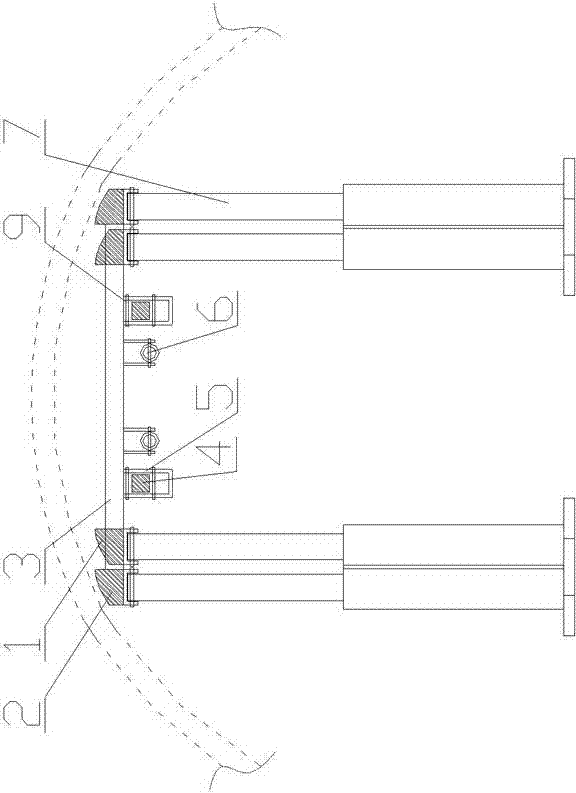

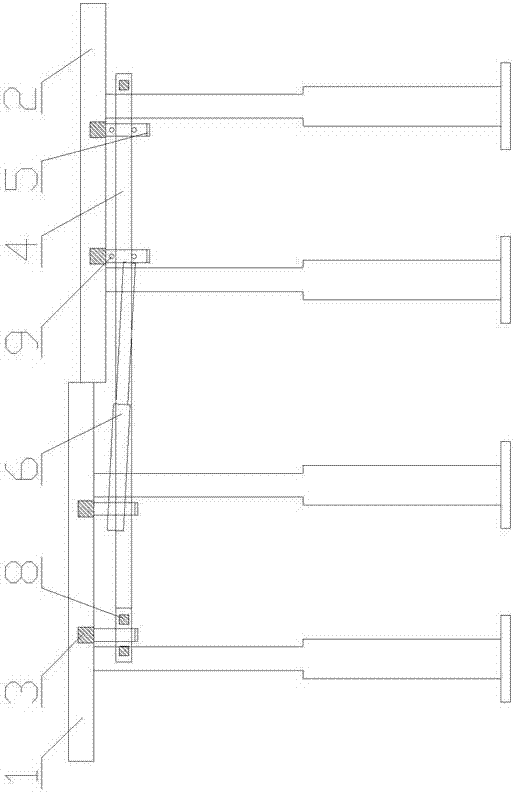

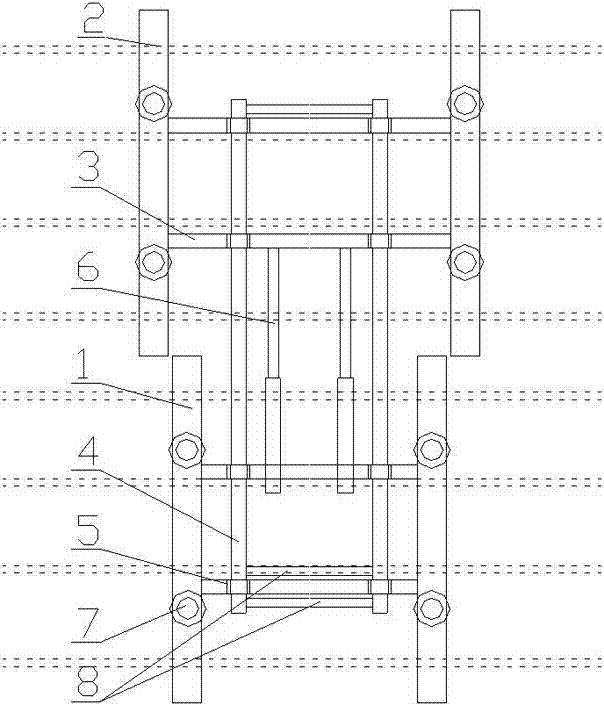

[0021] The following combined with the attachment to further explain the present invention:

[0022] like figure 1 As well as figure 2 As well as image 3 It shows that the shed lane lanes are used to move the tip of the hydraulic support device, including the front bracket and the rear bracket.The parallel rear vertical beam 1; the peaceful rear section beam 1 between the parallel front beam 2 between the parallel front beam 2; there are two below the beam 3 of each beam 3 of each beam 3The beam slide 5, located in the Tuliang 4 within the beam slide 5 to connect the front bracket with the rear bracket; the Beiliang 4 played a role in supporting the weight and track of the bracket during the shift process;

[0023] The rear vertical beams 1. The hinge with 7 hydraulic columns below the second vertical beam 2, respectively. The support height of the oil cylinder support is adjusted according to the height of the lane lane.

[0024] The adjacent beams connected to the adjacent beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com