Like concrete filling material suitable for road large cavity goaf treatment

A kind of concrete-like, filling material technology, applied in the field of road goaf treatment, can solve the problems of stone rate, low filling rate, single selection of grouting material, difficult control of slurry diffusion, etc., to achieve high stone rate, meet transmission requirements, The effect of reducing the amount of storage on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below.

[0040] 1. Raw material selection

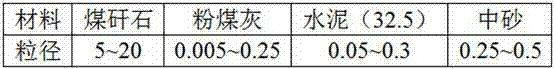

[0041] (1) Comprehensively consider the convenience of local materials in Shanxi Province, the economic cost and the environmental protection value, choose fly ash and coal gangue as the main constituent materials of concrete, turn waste into treasure, and realize the recycling of resources; choose 5 Coal gangue with a particle size of ~20mm forms a concrete-like skeleton structure to form an effective strength support; fly ash and medium sand are selected as ingredients to fill the gaps between the skeletons formed by coal gangue to form a reasonable gradation mixture as a whole , It can not only form concrete with a certain strength, but also meet the requirements of compactness; and the finally formed concrete-like can meet the transmission demand of pumping, and can fill the goaf more conveniently.

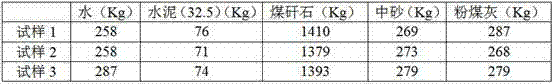

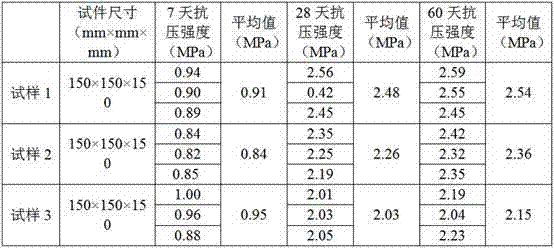

[0042] 2. Material ratio and strength test

[0043] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com