Slag powder and coal ash grouting-filling material and preparation method thereof

A technology for filling material and fly ash, which is applied in the field of slag fly ash grouting filling material and its preparation, and can solve the problems of low stone rate, large drying shrinkage, and many micro-cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

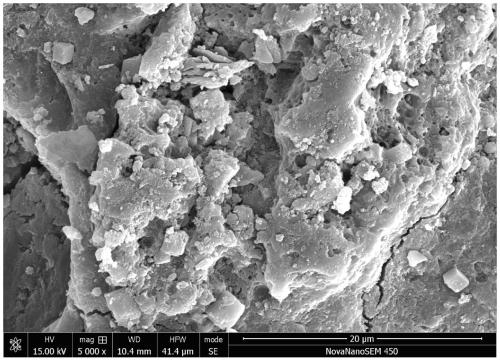

Image

Examples

preparation example Construction

[0031] A kind of slag fly ash fly ash grouting filling material preparation method of the present invention comprises following specific steps:

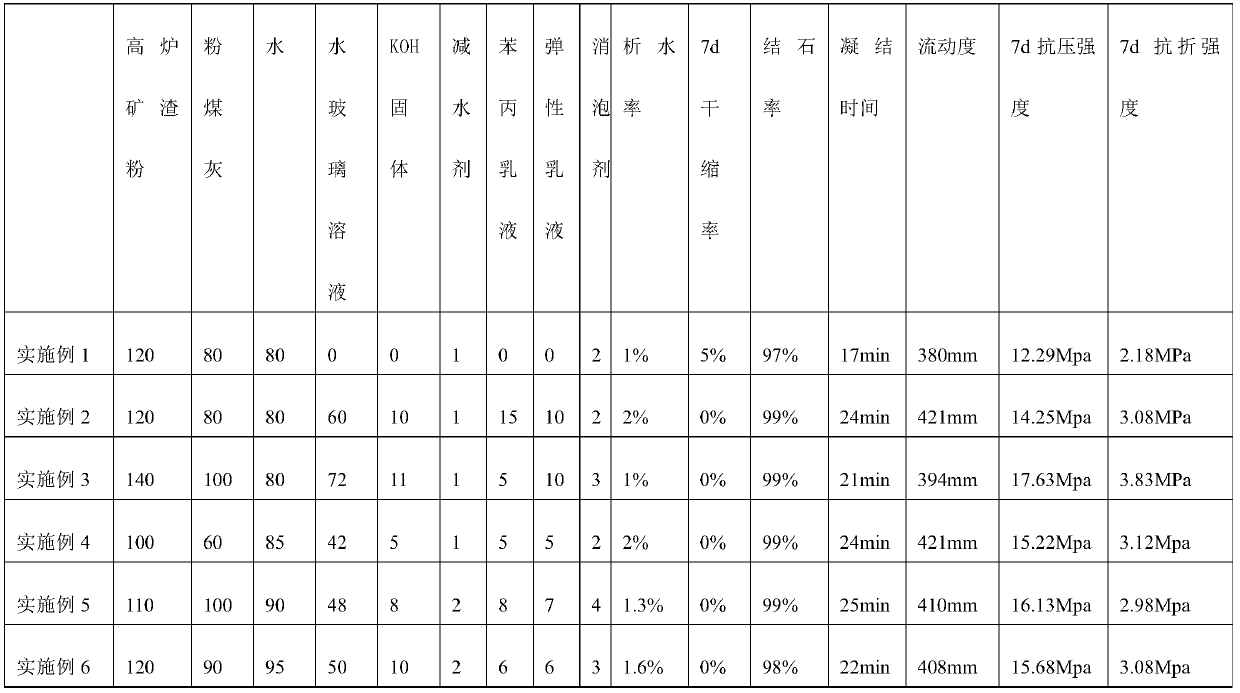

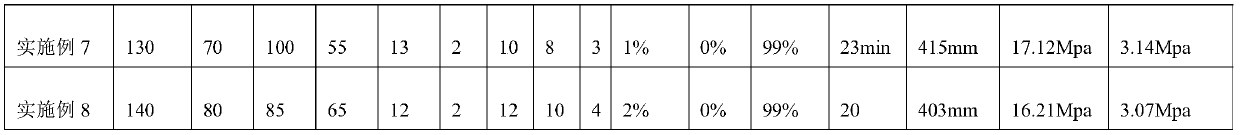

[0032] Step 1), weighing raw materials according to mass fraction: including 100-140 parts of blast furnace slag powder, 60-100 parts of fly ash, 80-100 parts of water, 42-72 parts of water glass solution, and 5-15 parts of KOH solid , 5-15 parts of styrene-acrylic emulsion, 5-10 parts of elastic emulsion, 2-4 parts of defoamer and 1-2 parts of water reducing agent;

[0033] Prepare B solution: Mix the weighed water glass solution and KOH solid until the KOH solid is completely dissolved in the water glass solution to obtain B solution; specifically, pour the KOH solid into the water glass solution and stir slowly until it is completely dissolved;

[0034] Step 2), mix well weighed blast furnace slag powder, fly ash, water reducer, water, elastic emulsion and styrene-acrylic emulsion to obtain A mixture; specifically, mix blast furna...

Embodiment 1

[0036] Embodiment 1 Preparation of existing geopolymer grouting filling material:

[0037] Step 1), according to the mass fraction, weigh raw materials: 120 parts of blast furnace slag powder, 80 parts of fly ash, 80 parts of water, 70 parts of dispersion liquid, 1 part of water reducer, 2 parts of defoamer;

[0038] Step 2), pour the weighed KOH solid into the water glass solution and stir slowly until the KOH solid is completely dissolved to obtain the B solution;

[0039] Step 3), put the weighed blast furnace slag powder and fly ash into the mixer and stir evenly, then put in the water reducer and water in turn, and stir at 100r / min for 5min to obtain the A mixture;

[0040] Step 4), pour the prepared solution B into the mixture A, add a defoamer, and stir at 300 r / min for 3 minutes to obtain a grouting filling material.

[0041] Use the grouting pressure pump and the grouting pipe to inject the grouting filling material into the designated area for the grouting filling e...

Embodiment 2

[0043]Step 1), weigh raw materials according to mass fraction: 120 parts of blast furnace slag powder, 80 parts of fly ash, 80 parts of water, 60 parts of water glass solution, 10 parts of KOH solid, 15 parts of styrene-acrylic emulsion, 10 parts of elastic emulsion , 1 part of water reducer, 2 parts of defoamer;

[0044] Step 2), pour the weighed KOH solid into the water glass solution and stir slowly until the KOH solid is completely dissolved to obtain the B solution;

[0045] Step 3), put the weighed blast furnace slag powder and fly ash into the mixer and stir evenly, then put in the water reducer and water in turn, and stir at 100r / min for 5min to obtain the A mixture;

[0046] Step 4), pour the prepared solution B into the mixture A, add a defoamer, and stir at 300 r / min for 3 minutes to obtain a grouting filling material.

[0047] Use the grouting pressure pump and the grouting pipe to inject the grouting filling material into the designated area for the grouting fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Clotting time | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com