Early-strength erosion-resistant clay cement paste

A technology of anti-erosion and clay water, which is applied in the field of clay cement paste, can solve the problems of hindering the curing speed of the slurry, not suitable for large-scale, large-scale engineering, and reducing the fluidity of materials, so as to reduce the elastic modulus and grouting Material cost, solution to operational instability of bentonite, improvement of calculus rate and effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In Embodiment 1, the early-strength and anti-erosion clay cement slurry includes clay cement slurry and supporting modifiers, wherein the clay cement slurry is mainly composed of clay raw slurry, cement (PO42.5 Portland cement) , fly ash and water. The clay raw slurry is mainly made by mixing clay and water. In engineering practice, modifiers are added to the clay cement slurry. The amount of modifiers (the amount of modifiers accounts for The proportion of mass) is about 2%. The modifier is mainly made of a: sodium metaaluminate, b: sodium metasilicate pentahydrate powder, c: polyacrylamide and d: aluminum sulfate. The following table is selected The four groups of mass ratios in 1, the measured initial fluidity, erosion resistance rate, and stone body strength are shown in Table 1.

[0029]

Embodiment 2

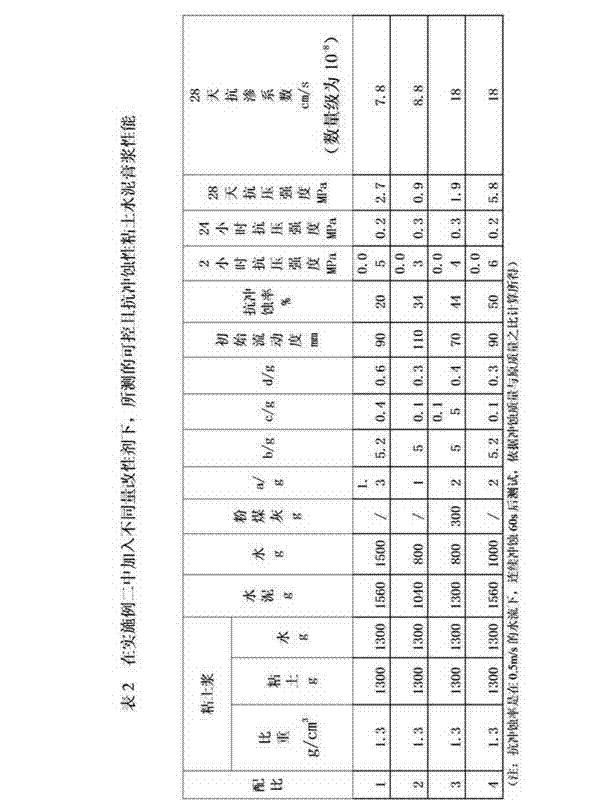

[0031] In embodiment two, the clay cement slurry with early strength and erosion resistance includes clay cement slurry and a supporting modifier, wherein the clay cement slurry is mainly composed of clay original slurry, cement (PO42.5 Portland cement) , water and a small amount of modifier. The clay raw slurry is mainly made by mixing clay and water. The modifier content (the ratio of the modifier content to the cement mass) is 0.5%. The modifier is mainly composed of a : sodium metaaluminate, b: sodium metasilicate nonahydrate powder, c: polyacrylamide and d: aluminum sulfate are physically mixed and made, selected four groups of mass ratios in the following table 2, and measured the initial fluidity, resistance The erosion rate and stone body strength are shown in Table 2.

[0032]

[0033] And randomly select one group of anti-erosion clay cement slurry in above-mentioned two groups of embodiments to carry out erosion, and its slurry slurry erosion photo is as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com