Chocolate casting machine

A chocolate and rack technology, applied in the fields of cocoa, food science, application, etc., can solve the problems of unfavorable stacking storage and transportation, inconvenient melting of bulk raw materials, inconvenient measurement and quantification, etc. The effect of improving consistency and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

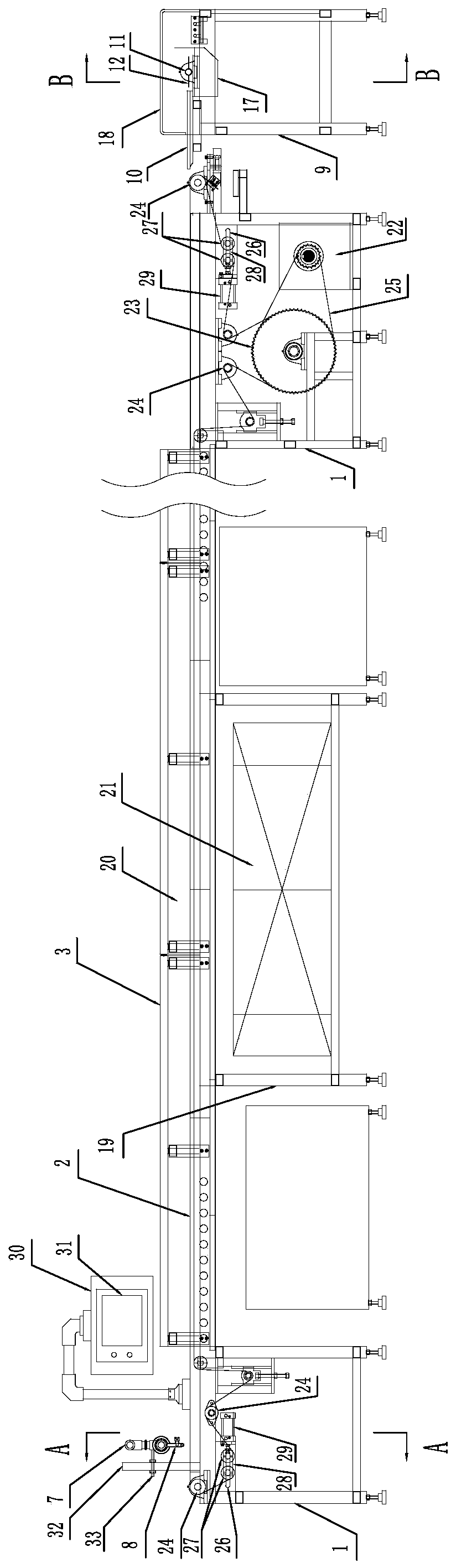

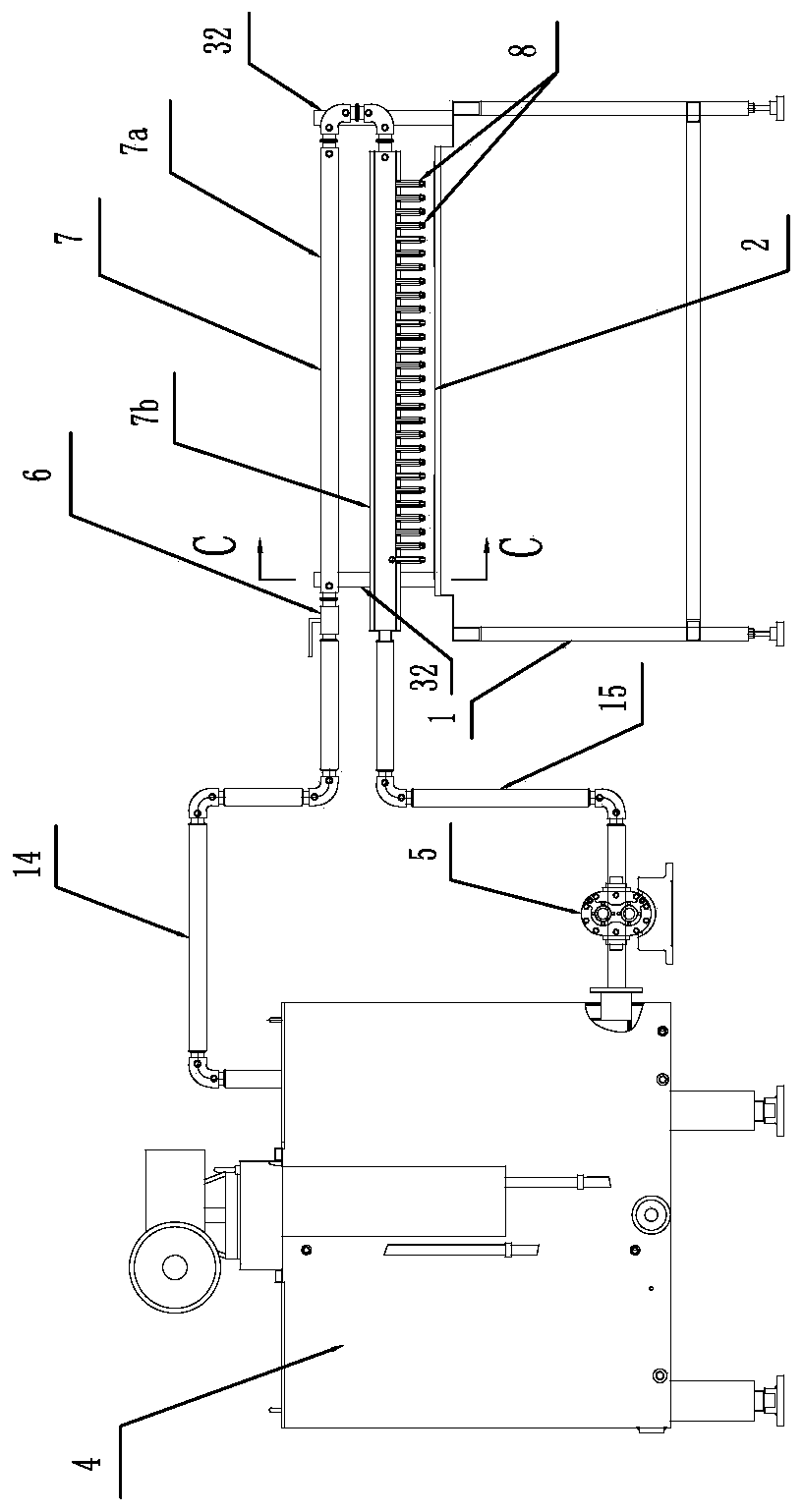

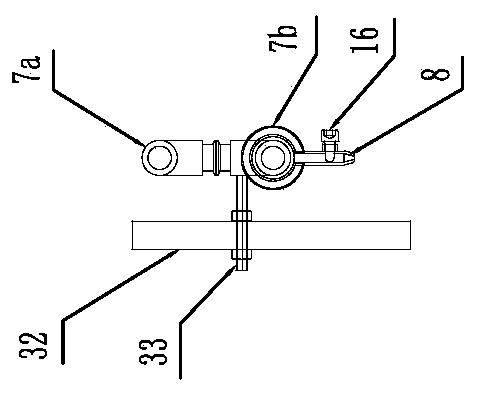

[0036] Embodiment: combine below Figure 1~Figure 4 Shown, the specific implementation of this chocolate pouring machine provided by the invention is described in detail as follows:

[0037] The chocolate pouring machine provided in this embodiment consists of a frame 1, a belt conveying mechanism located on the frame 1, a pouring head mechanism and a material breaking mechanism arranged at the front and rear ends of the belt conveying mechanism, and a pouring head mechanism and The cooling tunnel 3 for the belt to pass between the cutting mechanism and the controller 30 and the liquid crystal display 31 are jointly formed.

[0038] Specific as figure 1 As shown, the belt conveying mechanism is made up of an endless belt 2 and a belt driving device that drives the belt 2 to run. Like the conventional technology, because the whole body is longer, the frame 1 is divided into two front and rear, and the belt driving device has a belt reduction motor 22 1. The driving pulley 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com