Alkali-activated slag-based cement mixture grouting material and preparation method thereof

A grouting material and alkali-activated technology, which is applied in the field of construction engineering, can solve the problems of large cement consumption and low economic efficiency, and achieve the effects of high calculus rate, controllable setting time, and good recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

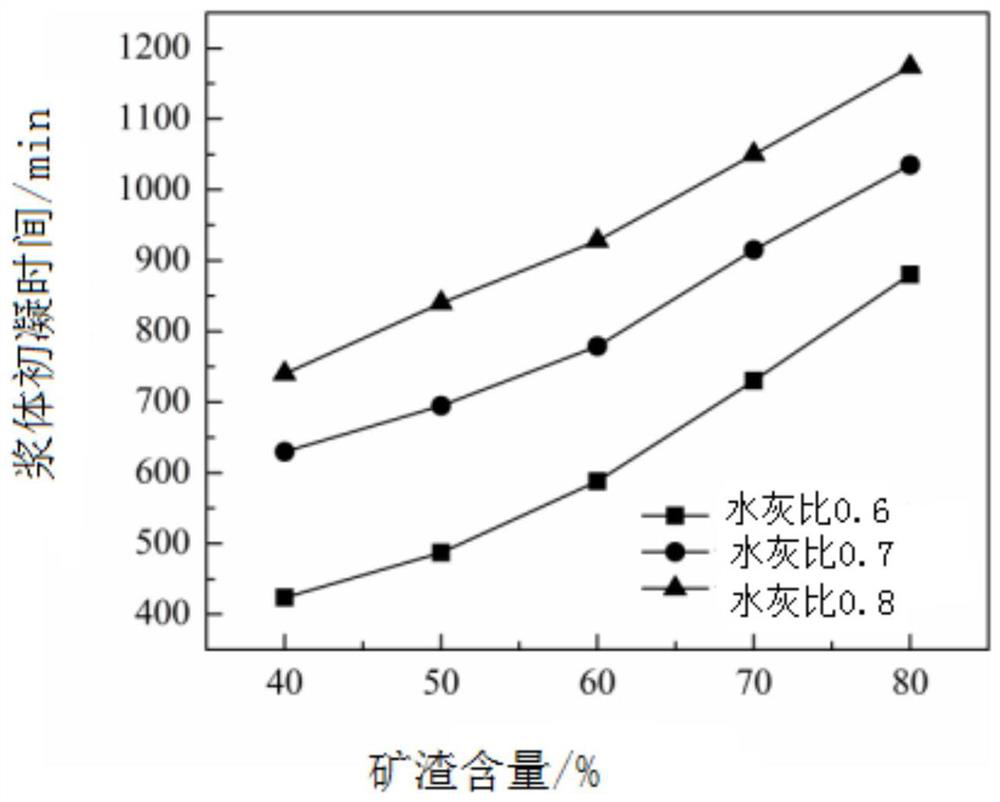

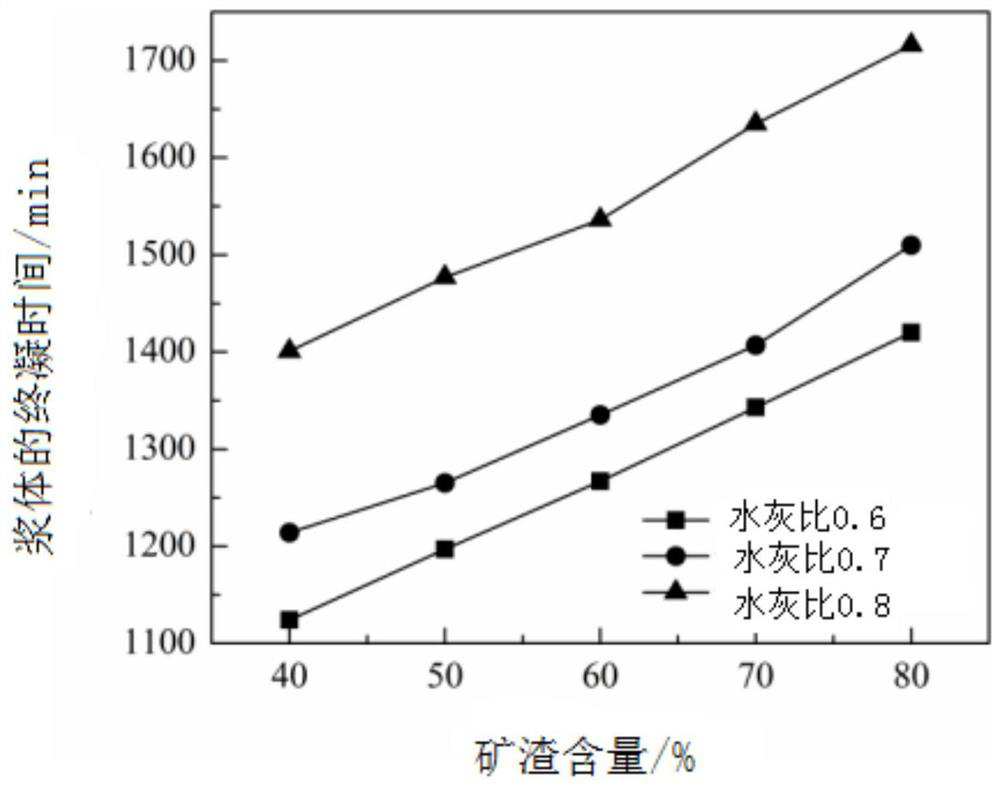

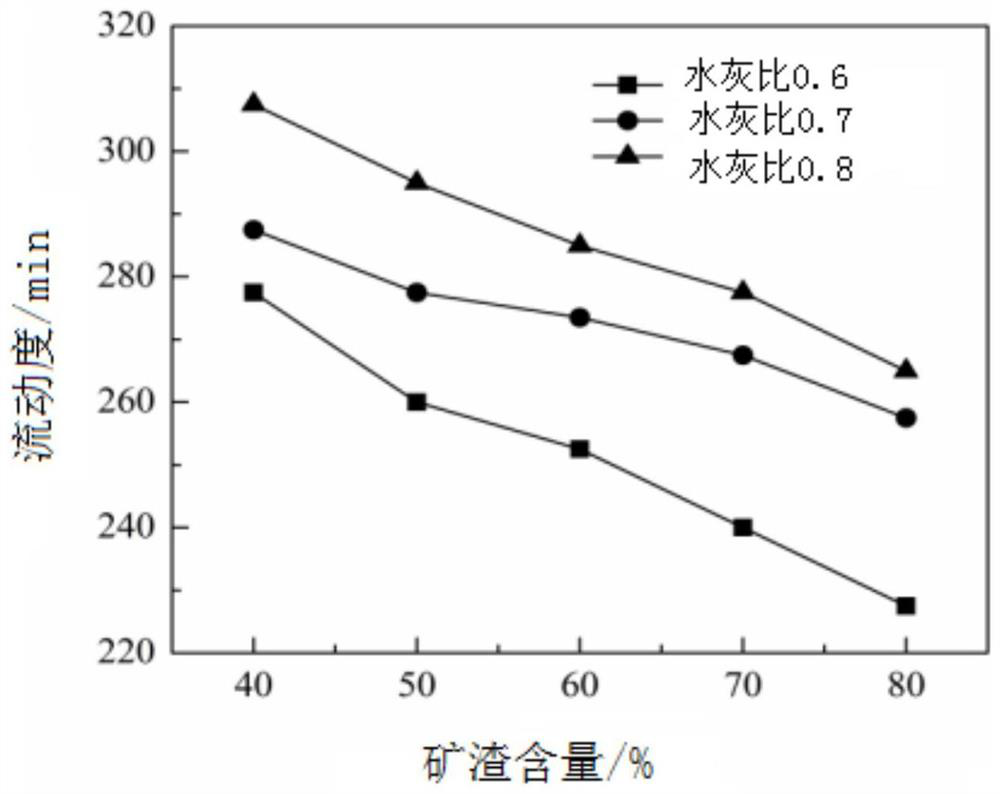

[0032] An alkali-activated slag-based cement mixture grouting material of the present embodiment comprises the following raw materials: Portland cement, water glass, slag and water, the water glass modulus is 3.3, and the Baume degree is 35Bé °, The main components of the slag are CaO and MgO, the water-solid ratio is 0.6, the mass ratio of Portland cement to slag is 0.25:1, and the mass ratio of water glass to the solid phase is 2%.

[0033] The preparation method of the grouting material of the present embodiment comprises the steps:

[0034] (1) according to the weight of each raw material, take by weighing for subsequent use;

[0035] (2) Add Portland cement, water glass, and slag to the stirring device, then add water for the first stirring, stop, the first stirring time is 110s, stop for 18s, and then carry out the second stirring, the second The time for the second stirring is 110s to obtain the grouting material.

Embodiment 2

[0037] An alkali-activated slag-based cement mixture grouting material of the present embodiment comprises the following raw materials: Portland cement, water glass, slag and water, the water glass modulus is 3.3, and the Baume degree is 35Bé °, The main components of the slag are CaO and MgO, the water-solid ratio is 0.7, the mass ratio of Portland cement to slag is 0.625:1, and the mass ratio of water glass to solid phase is 3%.

[0038] The preparation method of the grouting material of the present embodiment comprises the steps:

[0039] (1) according to the weight of each raw material, take by weighing for subsequent use;

[0040] (2) Add Portland cement, water glass, and slag to the stirring device, then add water for the first stirring, stop, the first stirring time is 120s, stop for 15s, and then carry out the second stirring, the second The time of secondary stirring is 120s to obtain the grouting material.

Embodiment 3

[0042] An alkali-activated slag-based cement mixture grouting material of the present embodiment comprises the following raw materials: Portland cement, water glass, slag and water, the water glass modulus is 3.3, and the Baume degree is 35Bé °, The main components of the slag are CaO and MgO, the water-solid ratio is 0.8, the mass ratio of Portland cement to slag is 1.5:1, and the mass ratio of water glass to solid phase is 4%.

[0043] The preparation method of the grouting material of the present embodiment comprises the steps:

[0044] (1) according to the weight of each raw material, take by weighing for subsequent use;

[0045] (2) Add Portland cement, water glass, and slag to the stirring device, then add water for the first stirring, stop, the time of the first stirring is 130s, stop for 12s, and then carry out the second stirring, the second The time for the second stirring is 130s to obtain the grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com