Economical high-strength and early strength grouting material and soft rock tunnel grouting reinforcement method

A grouting material and grouting reinforcement technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as slow grouting speed, poor grouting quality, large deformation disasters, etc., and achieve simple feeding and mixing, The effect of improving the accuracy of ingredients and improving the efficiency of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

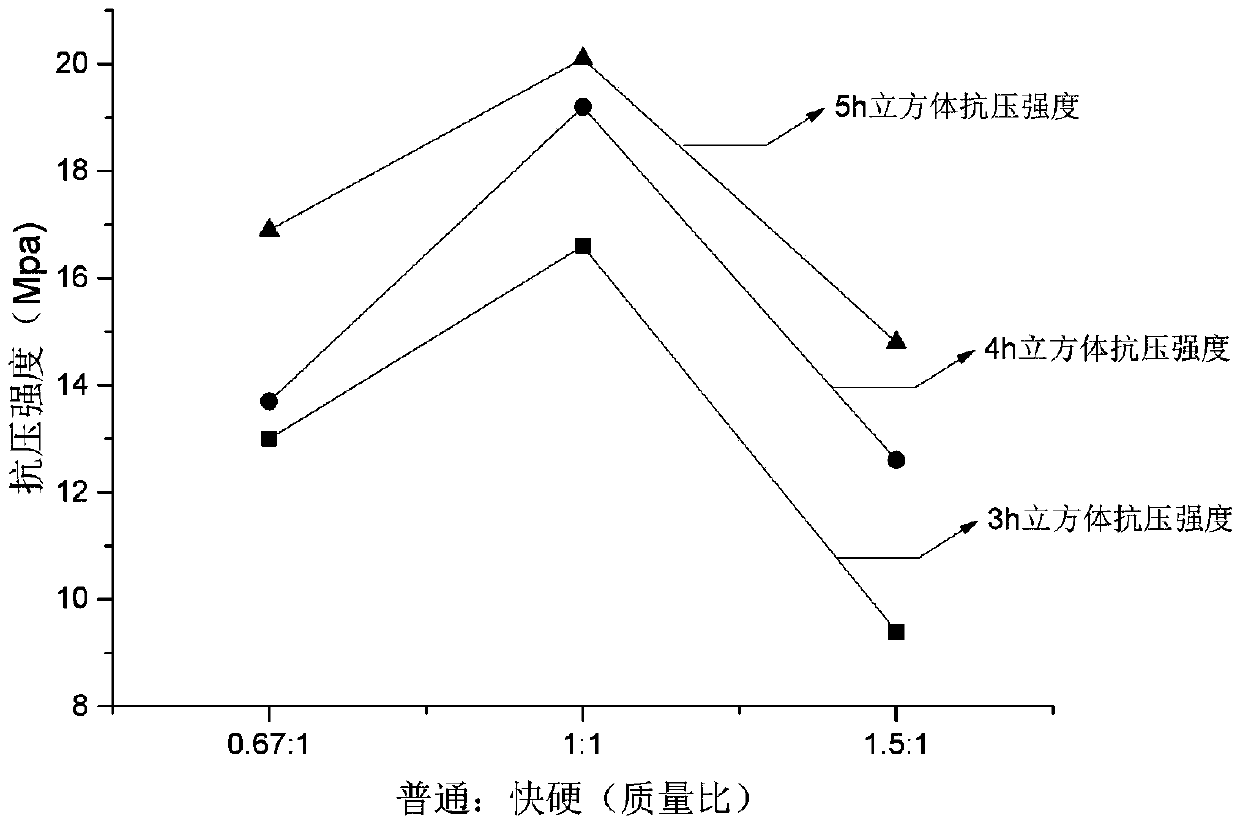

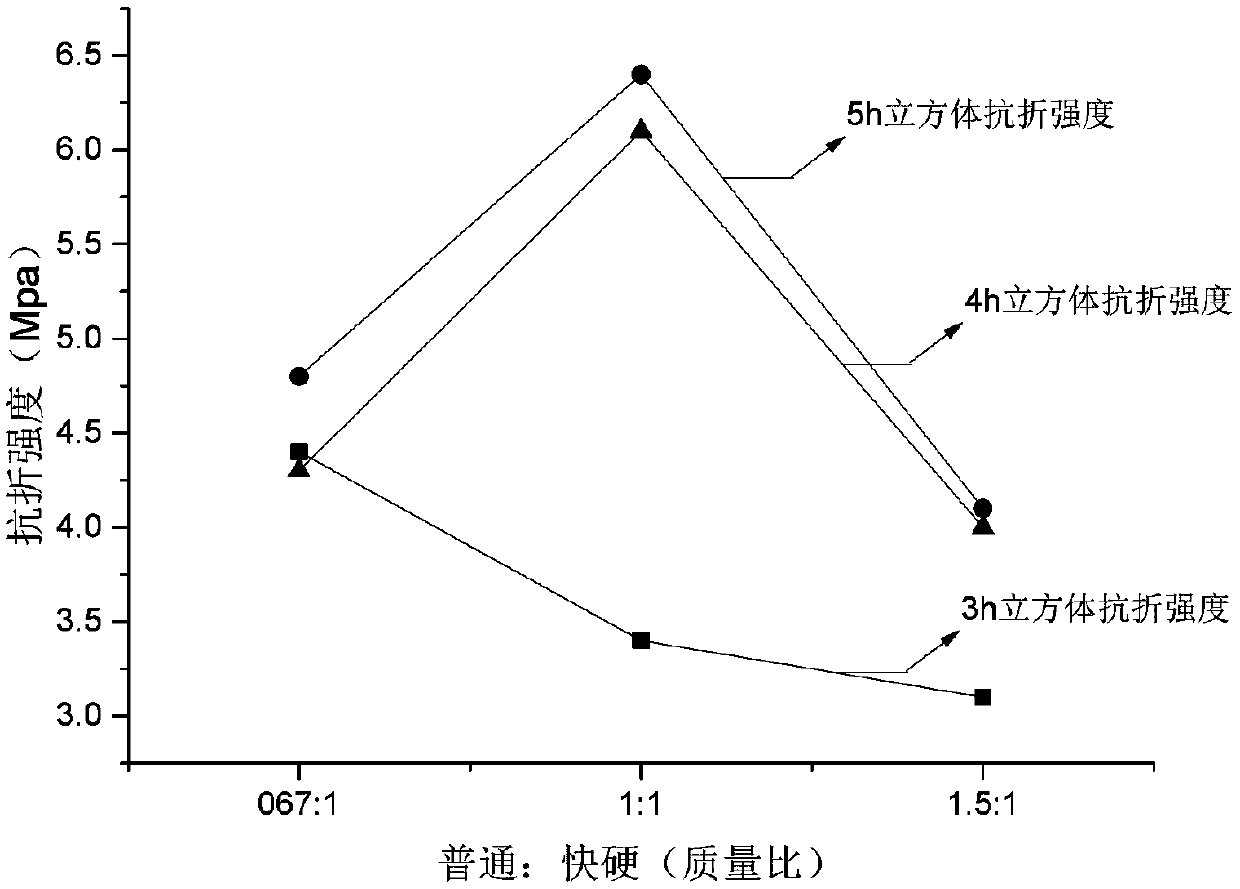

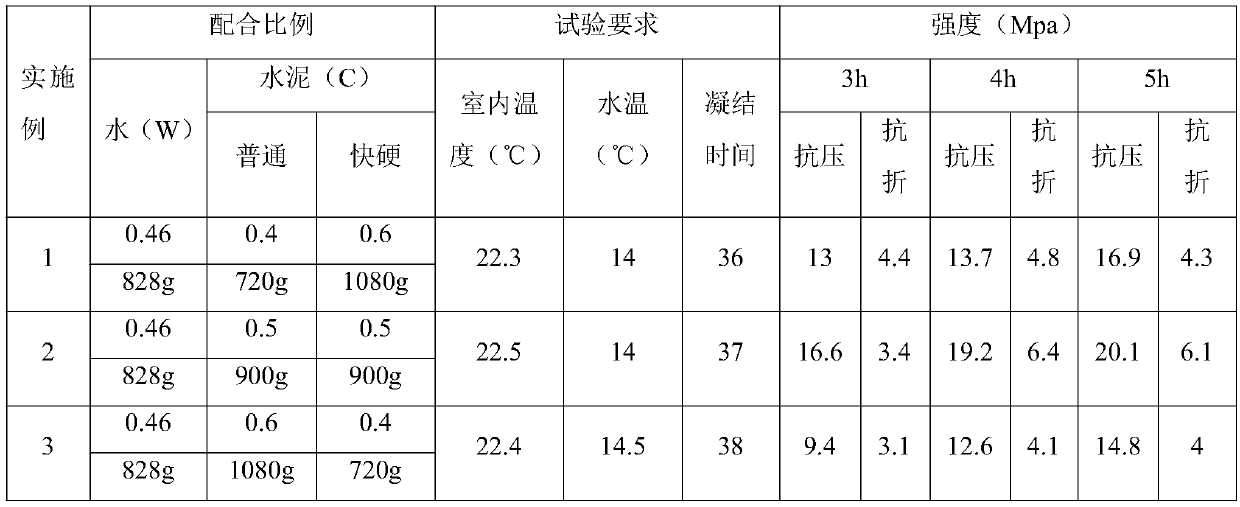

Embodiment 1

[0039] An economical high-strength rapid-hardening grouting material, including ordinary Portland cement, rapid-hardening sulfoaluminate gelling agent and water. Among them, the water-cement ratio is 0.46:1, and the mass ratio of fast-hardening sulfoaluminate gelling agent to ordinary Portland cement is 0.67:1. The grouting material prepared with this ratio can meet the requirements for weak carbon Requirements for bearing strength required for grouting of calcareous siliceous sandy slate interbedded with thin layers of phyllite.

Embodiment 2

[0041] An economical high-strength rapid-hardening grouting material, including ordinary Portland cement, rapid-hardening sulfoaluminate gelling agent and water. Among them, the water-cement ratio is 0.46:1, and the mass ratio of fast-hardening sulfoaluminate gelling agent to ordinary Portland cement is 1:1. The grouting material prepared with this ratio can meet the requirements for weak carbon Requirements for bearing strength required for grouting of calcareous siliceous sandy slate interbedded with thin layers of phyllite.

Embodiment 3

[0043] An economical high-strength rapid-hardening grouting material, including ordinary Portland cement, rapid-hardening sulfoaluminate gelling agent and water. Among them, the water-cement ratio is 0.46:1, and the mass ratio of fast-hardening sulfoaluminate gelling agent to ordinary Portland cement is 1.5:1. The grouting material prepared with this ratio can meet the requirements for weak carbon Requirements for bearing strength required for grouting of calcareous siliceous sandy slate interbedded with thin layers of phyllite.

[0044] The preparation method of the grouting material of the present invention is: mixing the quick-hardening sulphoaluminate gelling agent and the ordinary Portland cement according to the proportion, and then adding water and mixing evenly. Among them, the water-cement ratio is 0.46, and the mass ratio of the quick-hardening sulfoaluminate gelling agent to ordinary Portland cement is (0.67-1.5):1.

[0045] Further, the grouting parameters obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com