Paste injecting material of expansive soil cement paste

A technology of grouting material and expansive soil, which is applied in the field of grouting materials for expansive soil cement slurry, can solve the problems of different grouting effects, and achieve good water blocking effect, high calculus rate, and good grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

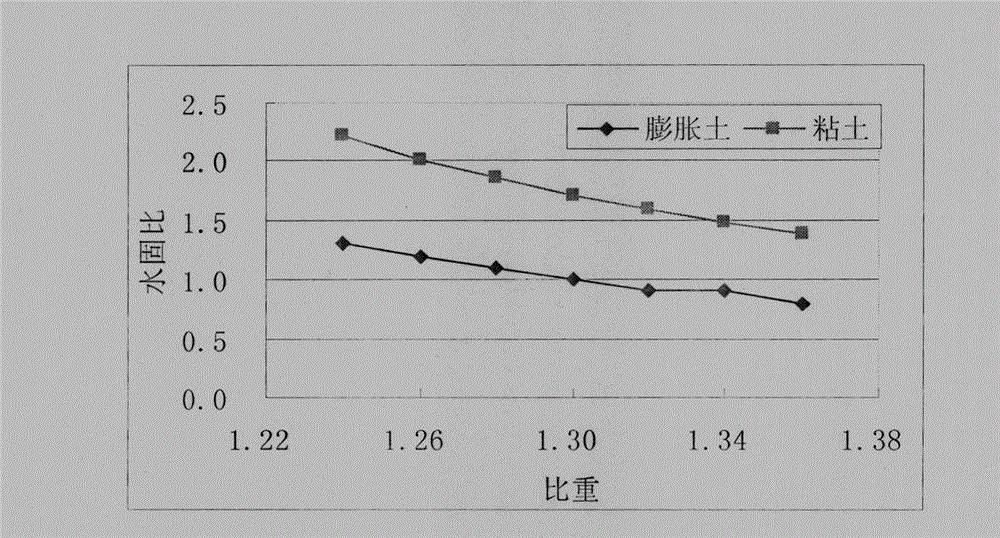

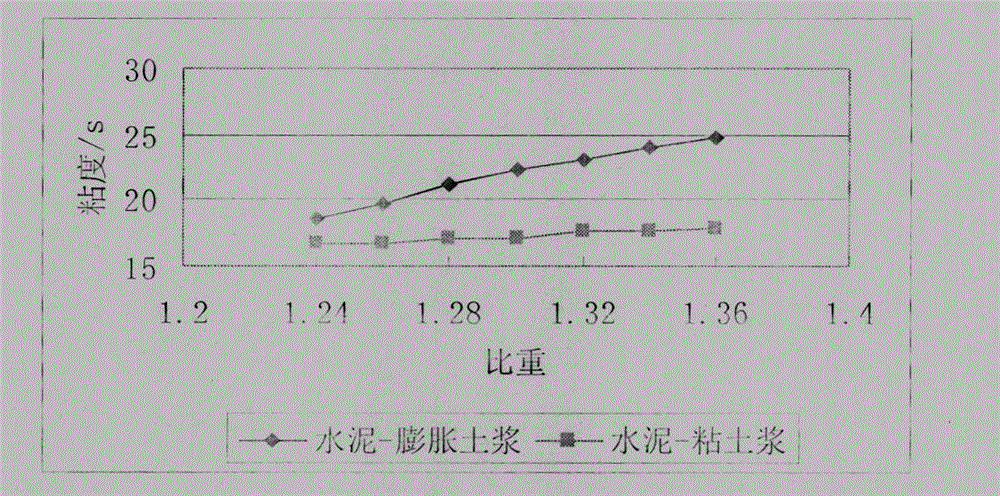

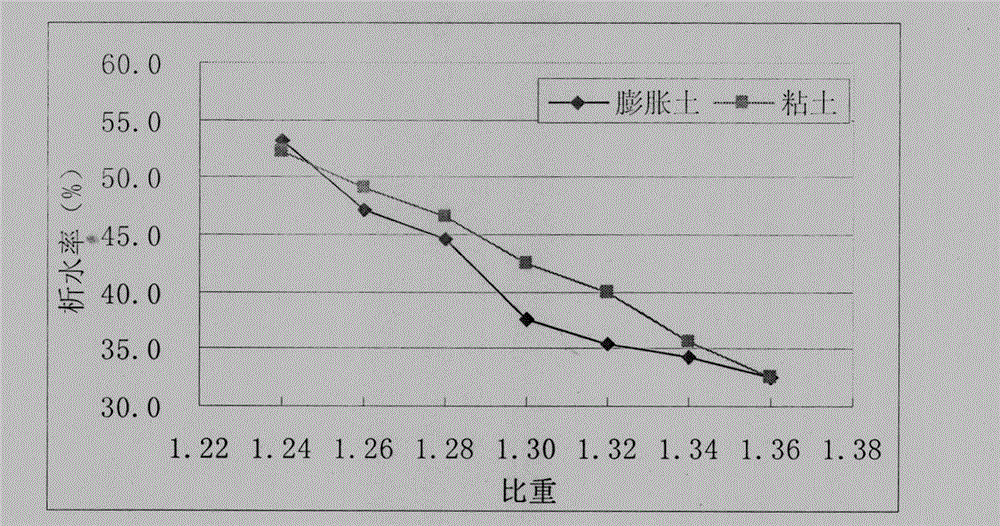

[0019] This embodiment includes expansive soil, cement and water, the weight ratio of expansive soil and cement is 3:7, the selected solid material is 120g, and the slurry ratio is 1.24. When the expansive soil passes through a 200-mesh sieve, the liquid limit of the expansive soil is 36.7%, the plastic limit is 19.7%, and the plasticity index is 17.0. The pH value of the water is 7.81, and the salinity is 665.30mg / L. The cement is PO42.5 ordinary Portland cement.

Embodiment 2

[0021] The slurry ratio of the present embodiment is 1.26, and other embodiments are the same as in Example 1.

Embodiment 3

[0023] The slurry ratio of this embodiment is 1.28, and other embodiments are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com