Modified tailing slurry and pulping and grouting process thereof

A tailings and modification technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of long cement-tailing mortar initial setting time, difficulty for tailing mortar to enter small cracks, and grouting materials waste and other issues, to achieve the effect of promoting green mine construction, improving injectable performance, and reducing engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

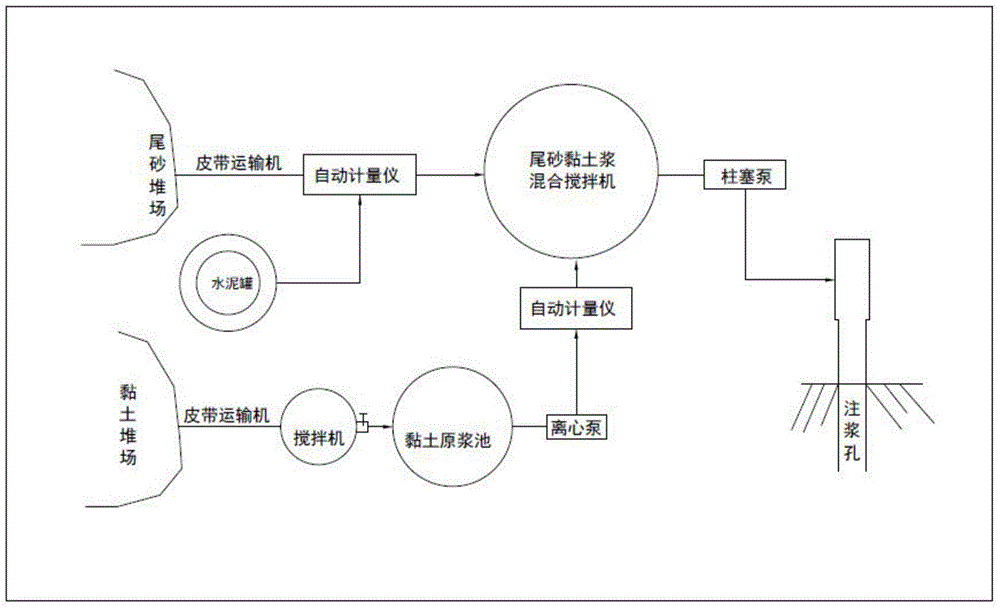

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0037] Due to the complex hydrogeological conditions of the Fankou lead-zinc mine deposit, the ground curtain grouting project is usually implemented to prevent water. From top to bottom, the strata revealed by the survey drilling of the curtain grouting and water blocking project are: Quaternary clay layer (Q), Hutian Group dolomitic limestone (C 2+3 ht), Carboniferous Datangian argillaceous limestone (C 1 ), the Devonian Tianziling Formation piebald limestone (D 3 t c ). Among them, the dolomitic limestone of the Hutian Group is the main aquifer and the main object of curtain grouting for water blocking. The main water inlet channel in the southeast of the min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com