High waterproof synchronous grouting grout for subsea shield tunnel

A technology of synchronous grouting and shield tunneling, which is applied in the field of building materials, can solve the problems of low shear resistance, complex construction, and low stone formation rate, and achieve high shear strength, reduced construction costs, and high filling coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

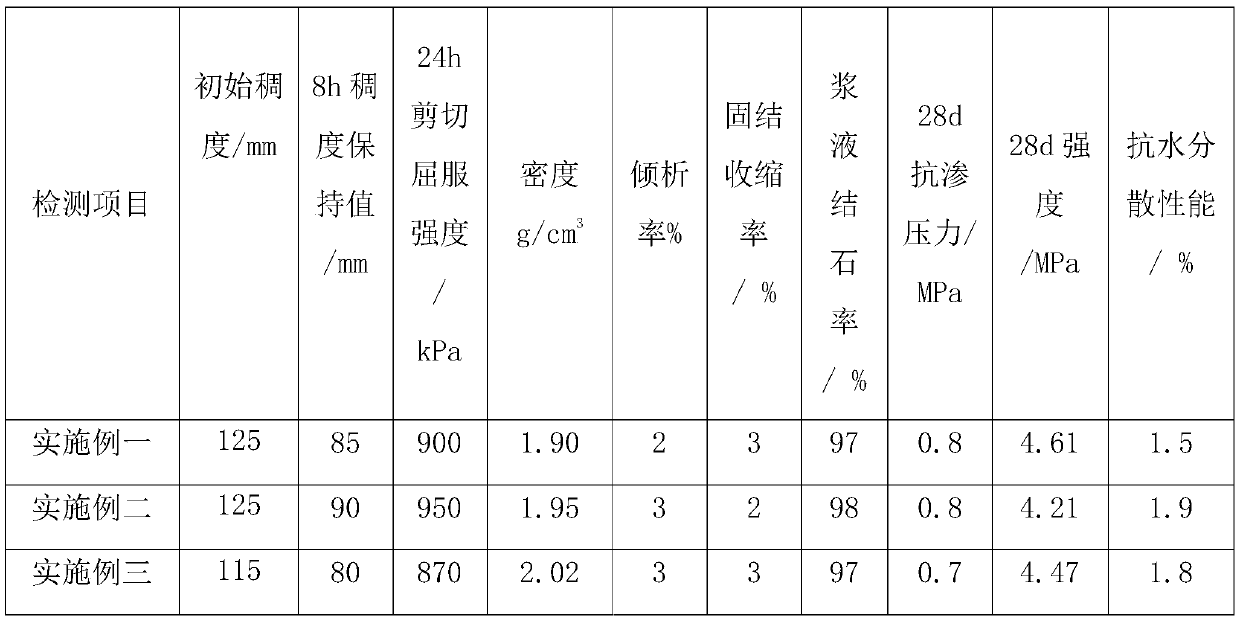

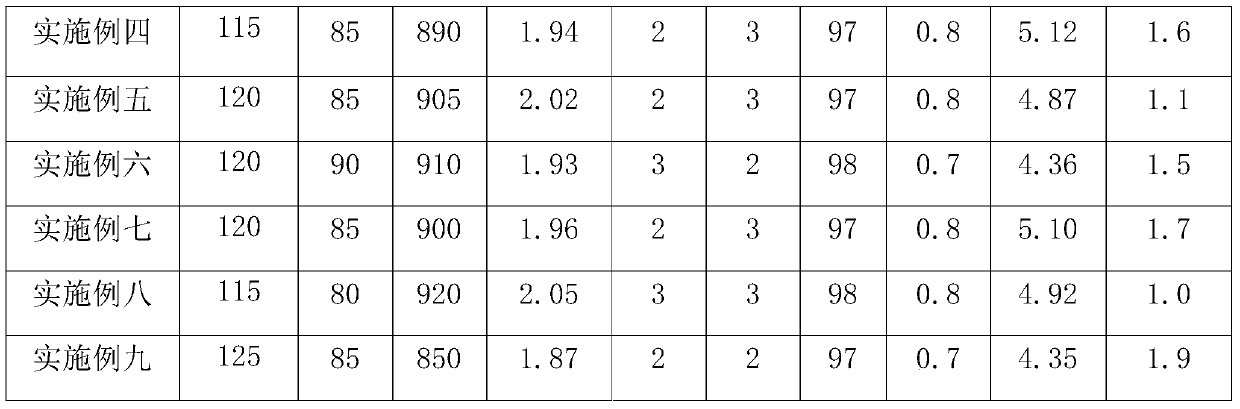

Examples

preparation example Construction

[0034] In this embodiment, the preparation method of the grouting slurry includes the following steps: first add hydroxypropyl methylcellulose, polyacrylamide, air-entraining agent, waterproofing agent and water-reducing agent into water and stir evenly, and then mix with cement, Mix finely ground limestone powder, slaked lime, sodium bentonite, and river sand, and stir evenly for at least 150 seconds.

[0035] In this embodiment, the raw material components of the slurry are all purchased from the market, and will not be repeated here.

Embodiment 1

[0038] The high waterproof synchronous grouting slurry for subsea shield tunnel provided by this embodiment, the slurry raw material includes the following components by weight percentage: 8.0% of cementitious material, 16.0% of ground limestone powder (150 mesh), sodium base Bentonite (200 mesh) 3.5%, river sand 58.0%, higher fatty acid waterproofing agent 0.240%, polycarboxylate superplasticizer 0.080%, hydroxypropyl methylcellulose (100 mesh) 0.040%, polyacrylamide (100 mesh ) 0.0080%, triterpene saponin air-entraining agent 0.0024% and water 14.1296%;

[0039] The cementitious material includes ordinary Portland cement and slaked lime (200 mesh), and the mass ratio of the ordinary Portland cement to slaked lime is 4.6:3.4.

[0040] In this example:

[0041] The fineness modulus of the river sand is 2.1;

[0042] The mass percent of montmorillonite in the sodium bentonite is 90%, and the expansion rate of the sodium bentonite is 25ml / g;

[0043] The water reducing rate o...

Embodiment 2

[0047] The high waterproof synchronous grouting slurry for subsea shield tunnel provided by this embodiment, the slurry raw material comprises the following components by weight percentage: 8.6% of cementitious material, 17.0% of ground limestone powder (180 mesh), sodium base Bentonite (150 mesh) 2.9%, river sand 57.0%, higher fatty acid waterproofing agent 0.258%, polycarboxylate superplasticizer 0.086%, hydroxypropyl methylcellulose (100 mesh) 0.043%, polyacrylamide (100 mesh ) 0.0086%, triterpene saponin air-entraining agent 0.00258% and water 14.10182%;

[0048] The cementitious material includes ordinary Portland cement and slaked lime (300 mesh), and the mass ratio of the ordinary Portland cement to slaked lime is 5.0:3.6.

[0049] In this example:

[0050] The fineness modulus of the river sand is 1.7;

[0051] The mass percentage of montmorillonite in the sodium bentonite is 90%, and the expansion rate of the sodium bentonite is 20ml / g;

[0052] The water reducing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com