Fabricated ballasting device for preventing shield tail from floating upwards

A prefabricated, shield-tail technology, applied in shaft equipment, shaft lining, mining equipment, etc., can solve problems such as the inability to change the relative position of the weight according to the requirements, the inability to quickly apply assembly and adjustment of the weight, and the impact of the construction process, etc. Achieve the effect of improving fixing efficiency, stable pressure and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

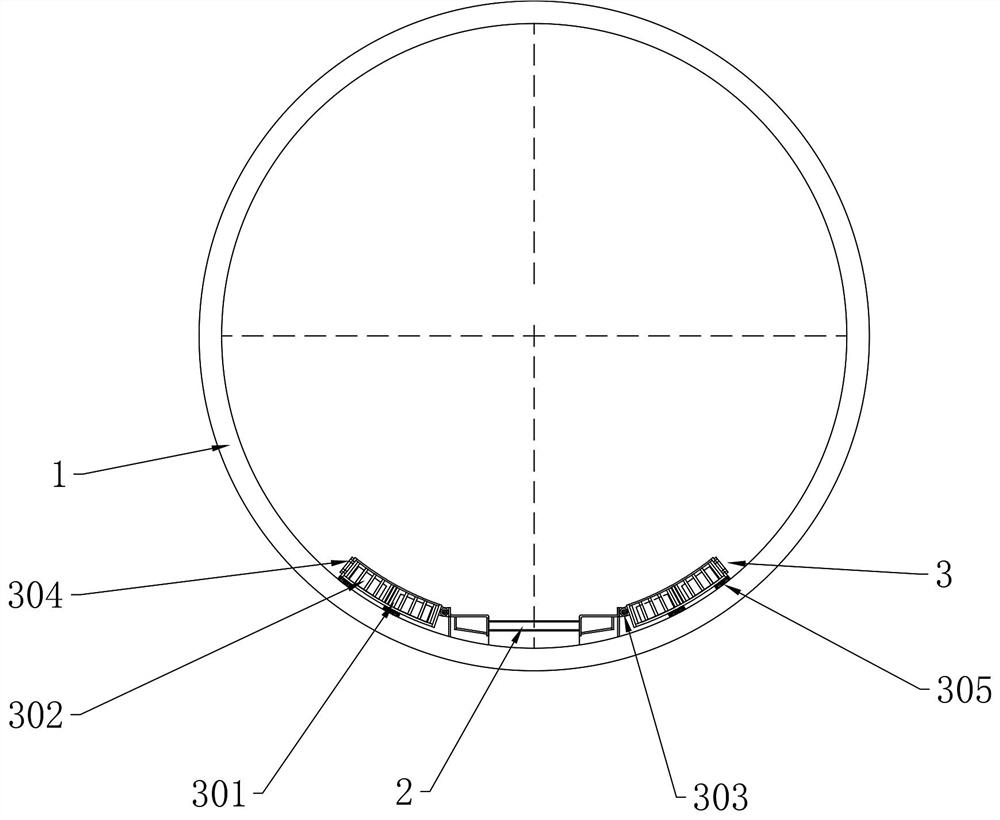

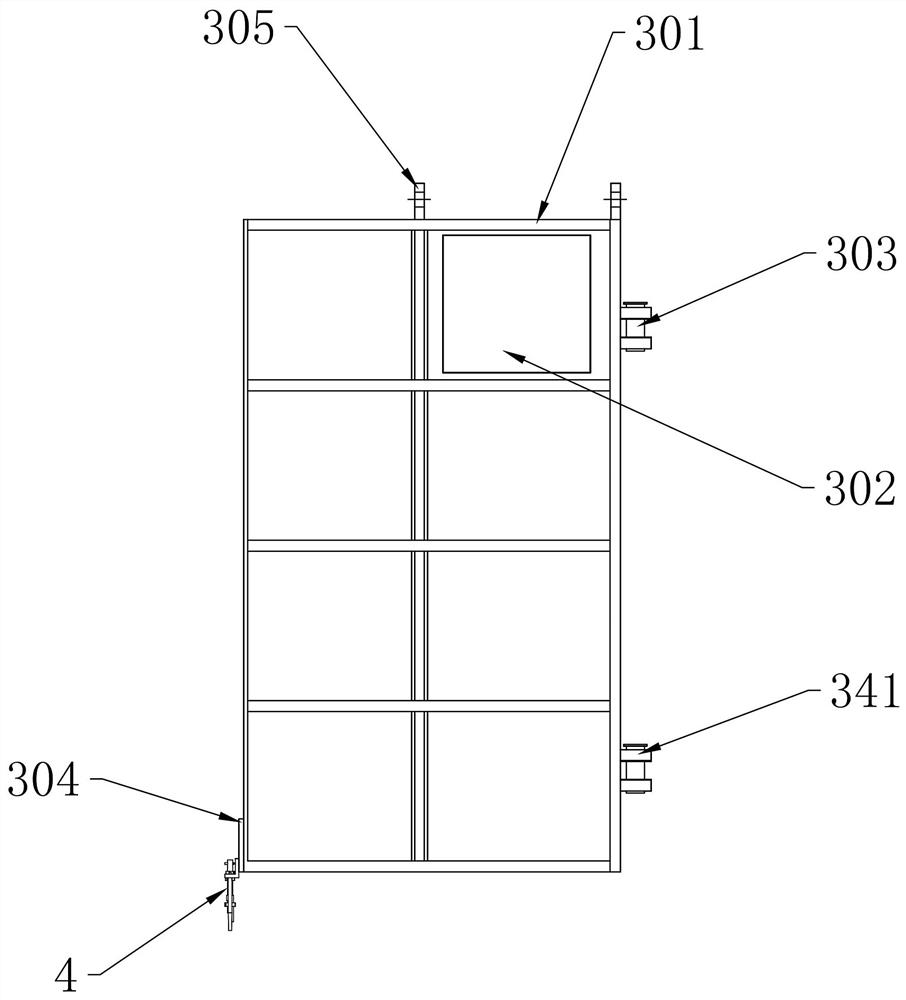

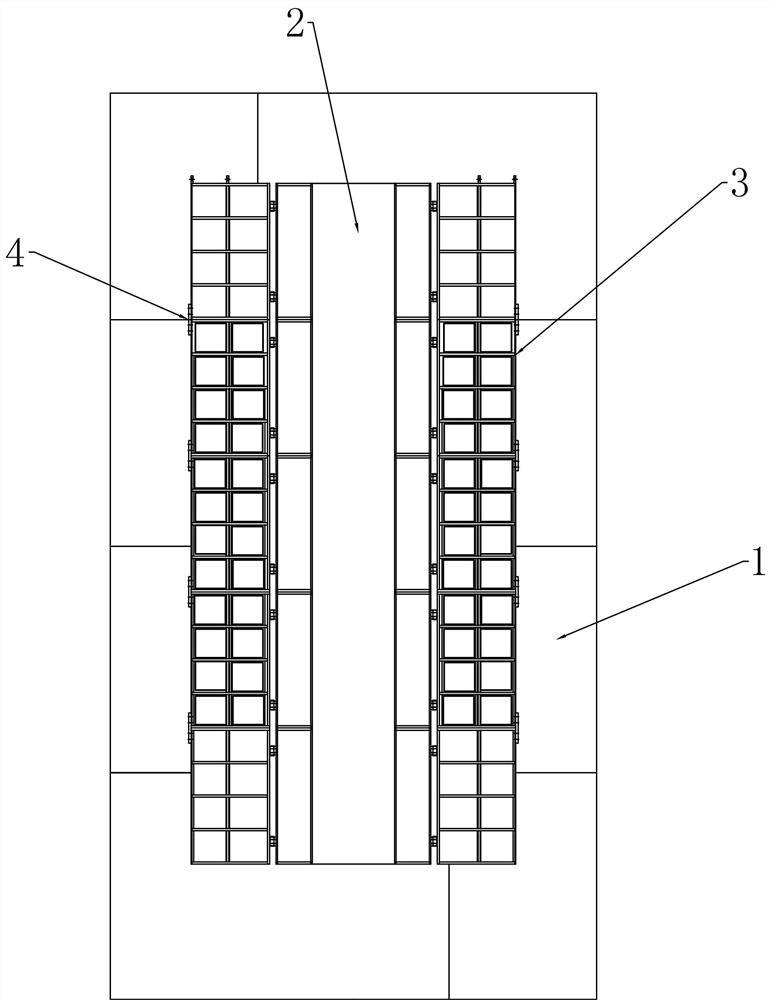

[0041] like Figure 1-12Among them, a prefabricated weight device for preventing the shield tail from floating, including a force applying unit 5 arranged on both sides of the tablet feeding machine 2, one side of the force applying unit 5 is hinged with the tablet feeding machine 2, and the force applying unit 5 includes A plurality of weighting devices 3 are arranged along the laying direction of the segment 1, a bearing plate 307 is arranged on the lower side of the weighting device 3, a steel frame 301 is arranged on the bearing plate 307, and a plurality of counterweight grooves are arranged in the steel frame 301 309, the counterweight body 302 is detachably provided in the counterweight groove 309, and the bottom of the load-bearing plate 307 is provided with a plurality of walking force transmission wheels 305, and the walking force transmission wheels 305 are slidingly connected with the segment 1; The devices 3 are connected through the connection unit 4 , and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com