Method for controlling upward floating of pipe piece during shield machine air pushing through mining tunnel

A mining method and shield machine technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of difficulty in controlling the floating of segments, single measures, and unfavorable stress on segments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

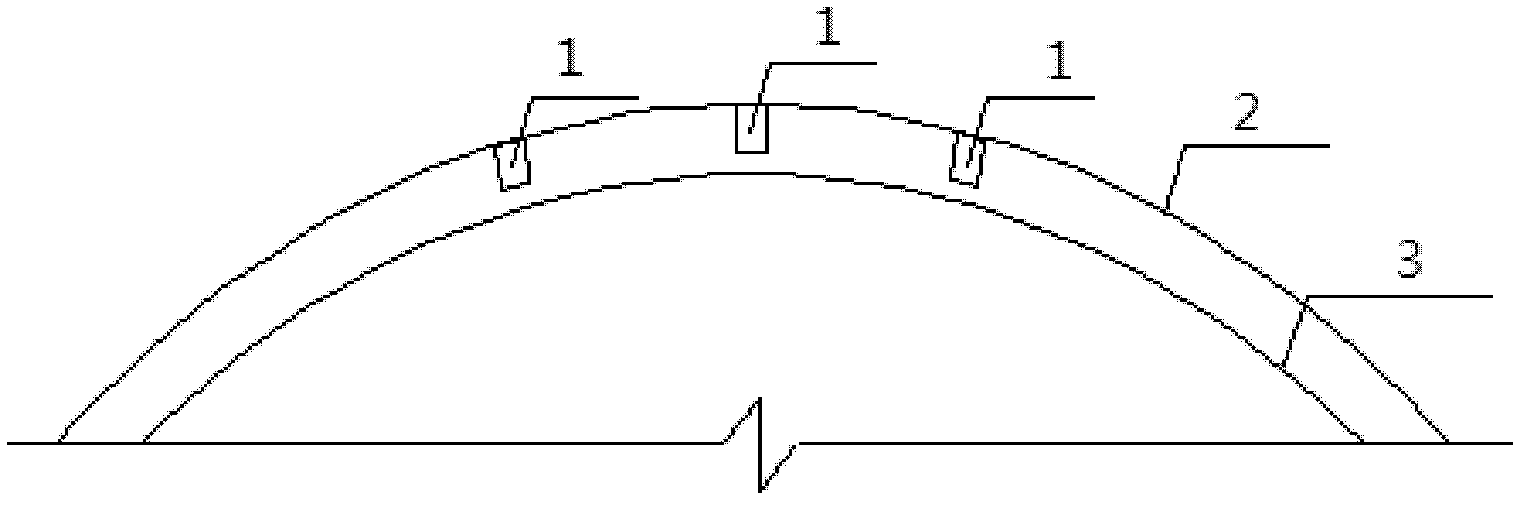

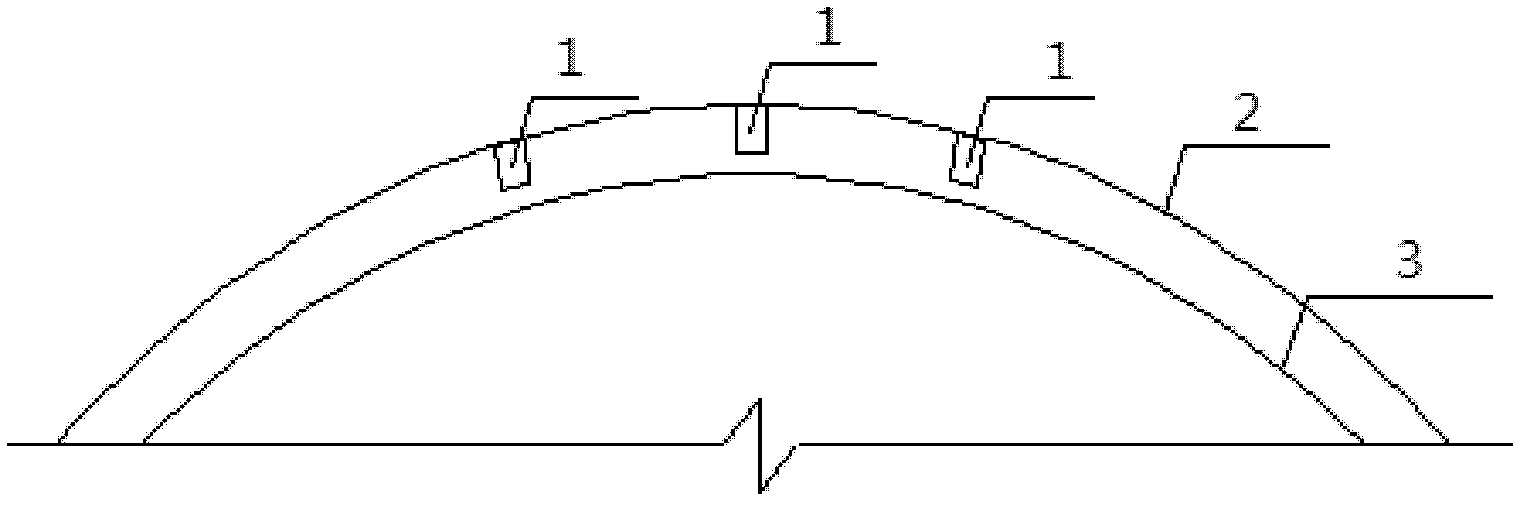

[0031] A civil shield tunnel for a subway project, in which the length of the middle part of the left line is 147.5m, and the length of the middle part of the right line is 287m, it is necessary to use the mining method to construct the initial lining of the tunnel, and then use the shield machine to assemble the segments and push them through The mine method tunnel forms the second lining of the tunnel.

[0032] In an embodiment of the present invention, pure cement slurry is made up of 32.5 grade cement and water, and mass volume ratio is 1: 1kg / L; Cement water glass double liquid slurry is made up of pure cement slurry and water glass, and the volume ratio of the two is 1:0.15.

[0033] In order to control the floating of the segment when the shield machine is pushed through the mine tunnel, the method of the present invention is adopted, and the specific control measures are as follows:

[0034] 1) if figure 1 As shown, the tunnel 2 formed by the mining method is measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com