Full-automatic plate trimming machine

An edge sawing machine, fully automatic technology, applied in the direction of grinding feed movement, grinding machine parts, grinding/polishing safety devices, etc., can solve the high production cost of automatic edge sawing machine, and can only transport one plate at a time and other problems, to achieve the effect of simple structure, simple and convenient maintenance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

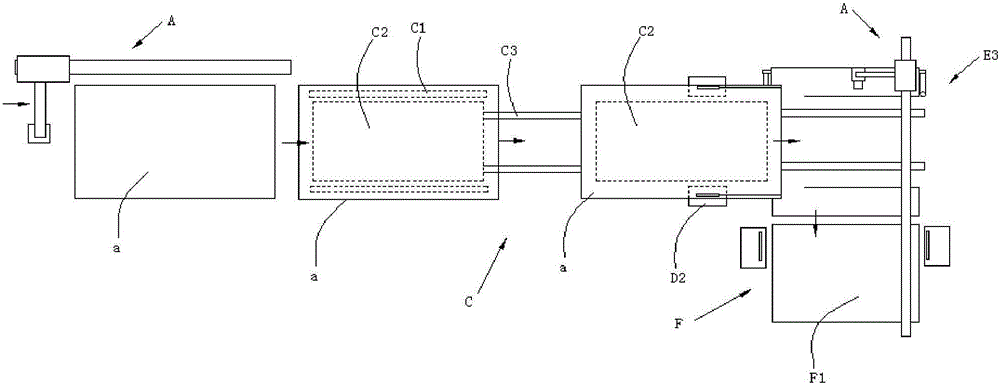

[0038] Such as figure 1 As shown, a full-automatic edge sawing machine for edge trimming of boards includes a feeding device A, a long side sawing device C, a steering device E3, and a short side sawing device F; the board passes through the feeding device A, the long side Side sawing device C, steering device E3, short side sawing device F. The long-side edge sawing device C and the short-side edge sawing device F are respectively located on two sides adjacent to the steering device E3, and the horizontal angle between the long-side edge sawing device C and the short-side edge sawing device F is 90°.

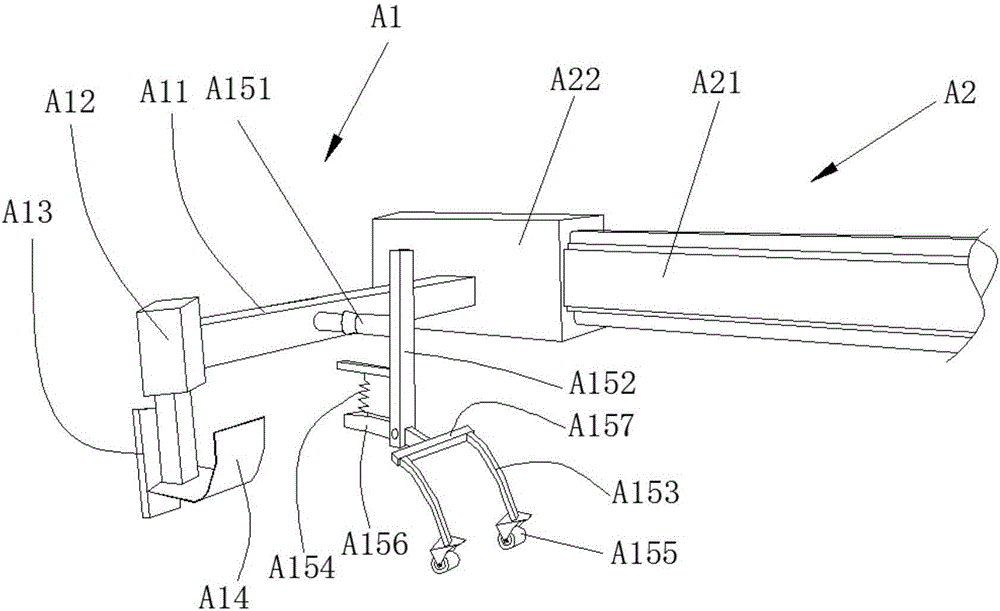

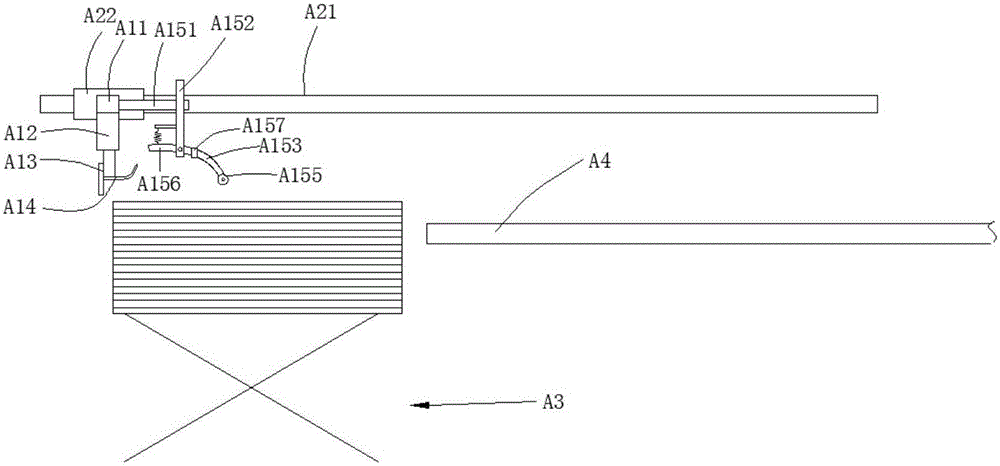

[0039] Such as figure 2 As shown, a feeding device of an automatic edge sawing machine, the feeding device includes a push plate me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com