Self-cleaning LED package coating and preparation method thereof

An LED packaging and self-cleaning technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as increased maintenance costs, reduced lifespan, unclear display, etc., to extend the lifespan, reduce the price, and reduce the difficulty of cleaning and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

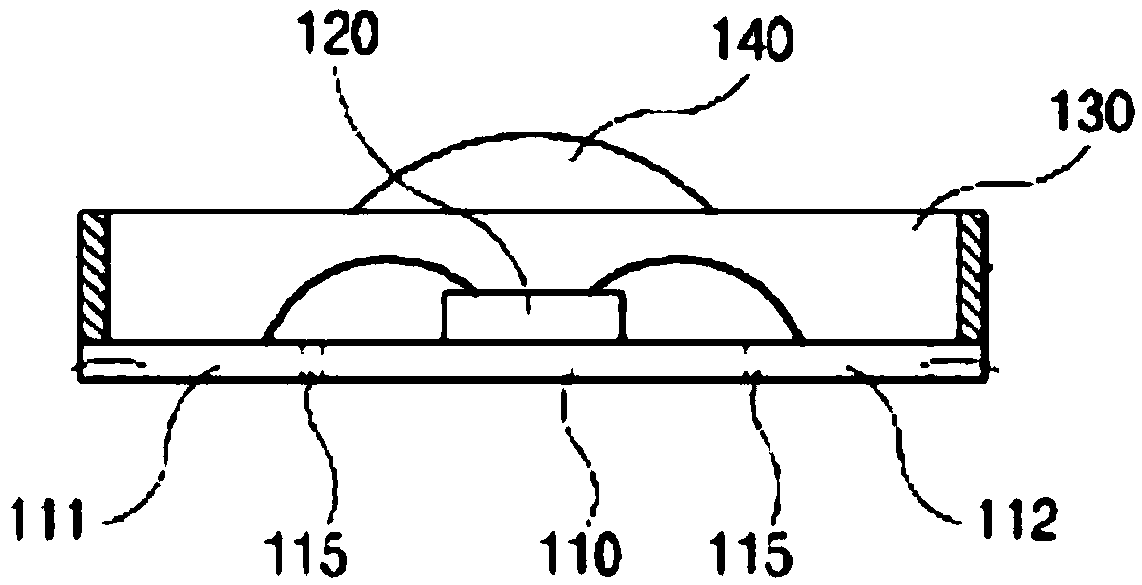

Image

Examples

Embodiment 1

[0015] Example 1: The self-cleaning coating includes 0.15 g of nanoscale titanium dioxide particles, 1 g of tridecafluorooctyltriethoxysilane and 100 g of absolute ethanol. The particle size of the titanium dioxide is 40nm.

[0016] Mix tridecafluorooctyltriethoxysilane with absolute ethanol, stir magnetically for 10 minutes to make it evenly mixed, add titanium dioxide particles, and stir magnetically for more than 30 minutes to obtain the required self-cleaning coating; during the whole stirring process The solution needs to maintain good sealing; after the metal substrate is packaged, immerse the entire lens part and the surface of the plastic package part in the paint for 30 seconds, then take it out and dry it to reach the superhydrophobic self-cleaning surface.

Embodiment 2

[0017] Example 2: The preparation method of Example 2 is the same as that of Example 1, the only difference being that the raw materials are different. The self-cleaning coating includes 0.1 g of nanoscale titanium dioxide particles, 0.5 g of tridecafluorooctyltriethoxysilane and 80 g of absolute ethanol. The particle size of titanium dioxide is 20 nm.

Embodiment 3

[0018] Example 3: The preparation method of Example 3 is the same as that of Example 1, the only difference being that the raw materials are different.

[0019] The self-cleaning paint includes 0.2 g of nanoscale titanium dioxide particles, 2 g of tridecafluorooctyltriethoxysilane and 120 g of absolute ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com