Easy-to-clean mildew-proof PP composite material and preparation method thereof

A composite material and easy-to-clean technology, applied in the field of PP composite materials, can solve problems such as good antistatic and antibacterial properties, and unknown easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing an easy-to-clean anti-mold PP composite material, the specific process is as follows:

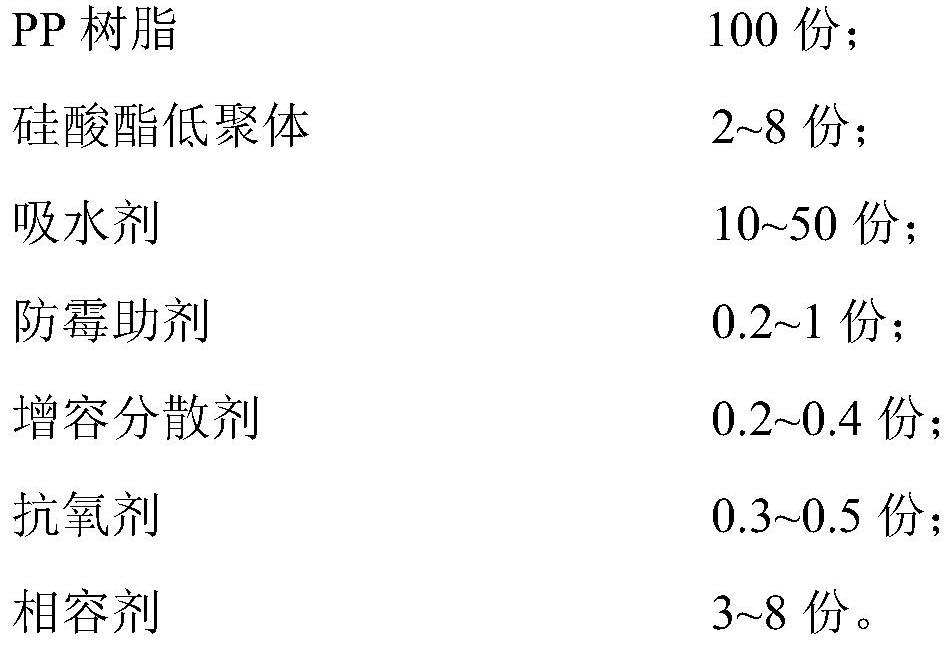

[0036] (1) Prepare raw materials by the following parts by weight:

[0037] 100 parts of PP resin;

[0038] MKC TM Silicate 8 parts;

[0039] 10 parts of water absorbent;

[0040] Zinc antifungal agent 0.5 parts;

[0041] High activity coupling dispersant YY-703 0.4 part;

[0042] 0.5 part of antioxidant;

[0043] Compatibilizer 3 parts.

[0044] Wherein, the water-absorbing agent is PA6 with a terminal amino group content of 55 mmol / kg.

[0045] The PP resin is a homopolymerized polypropylene resin with a melt index of 10g / 10min (230°C*2.16kg).

[0046] The compatibilizer is PP-g-MAH.

[0047] The active ingredient of the zinc-based antifungal agent is zinc pyrithione antifungal agent.

[0048] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168 with a mass ratio of 1:1.

[0049] (2) According to the above parts by weight, add PP resi...

Embodiment 2

[0052] A method for preparing an easy-to-clean anti-mold PP composite material, the specific process is as follows:

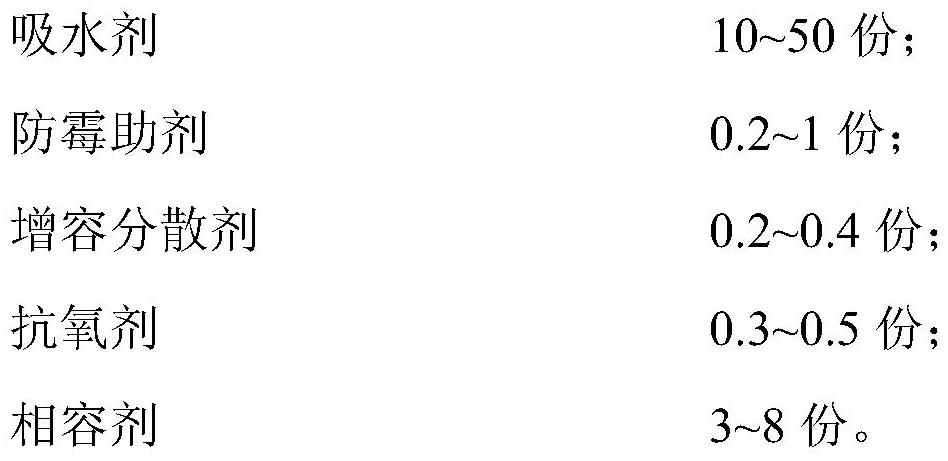

[0053] (1) Prepare raw materials by the following parts by weight:

[0054] 100 parts of PP resin;

[0055] MKC TM Silicate 2 parts;

[0056] 50 parts of water absorbent;

[0057] Zinc antifungal agent 1 part;

[0058] High activity coupling dispersant YY-703 0.3 part;

[0059] Antioxidant 0.3 part;

[0060] 8 parts of compatibilizer.

[0061] Wherein, the water-absorbing agent is PA66 with a terminal amino group content of 50 mmol / kg.

[0062] The PP resin is a block copolymerized polypropylene resin with a melt index of 20g / 10min (230°C*2.16kg).

[0063] The compatibilizer is POE-g-MAH.

[0064] The active ingredient of the zinc-based antifungal agent is zinc pyrithione antifungal agent.

[0065] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168 at a mass ratio of 2:1.

[0066] (2) Add PP resin, silicate oligomer, water-absorbing...

Embodiment 3

[0069] A method for preparing an easy-to-clean anti-mold PP composite material, the specific process is as follows:

[0070] (1) Prepare raw materials by the following parts by weight:

[0071] 100 parts of PP resin;

[0072] MKC TM Silicate 5 parts;

[0073] 15 parts of water absorbent;

[0074] Zinc antifungal agent 0.2 parts;

[0075] High activity coupling dispersant YY-703 0.2 parts;

[0076] Antioxidant 0.4 part;

[0077] 5 parts of compatibilizer.

[0078] Wherein, the water-absorbing agent is PA11 with a terminal amino group content of 54 mmol / kg.

[0079] The PP resin is a random copolymerized polypropylene resin with a melt index of 60g / 10min (230°C*2.16kg).

[0080] The compatibilizer is LLDPE-g-MAH.

[0081] The active ingredient of the zinc-based antifungal agent is zinc pyrithione antifungal agent.

[0082] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168 at a mass ratio of 1:2.

[0083] (2) According to the above parts by weight, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com