Polishing method for treating roughness and smoothness of metal structural surface

A technology of surface roughness and metal structure, which is applied in the field of grinding to deal with the surface roughness and finish of metal structures, can solve the problems of low grinding quality and precision, low work efficiency, etc., and achieve the effect of avoiding oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

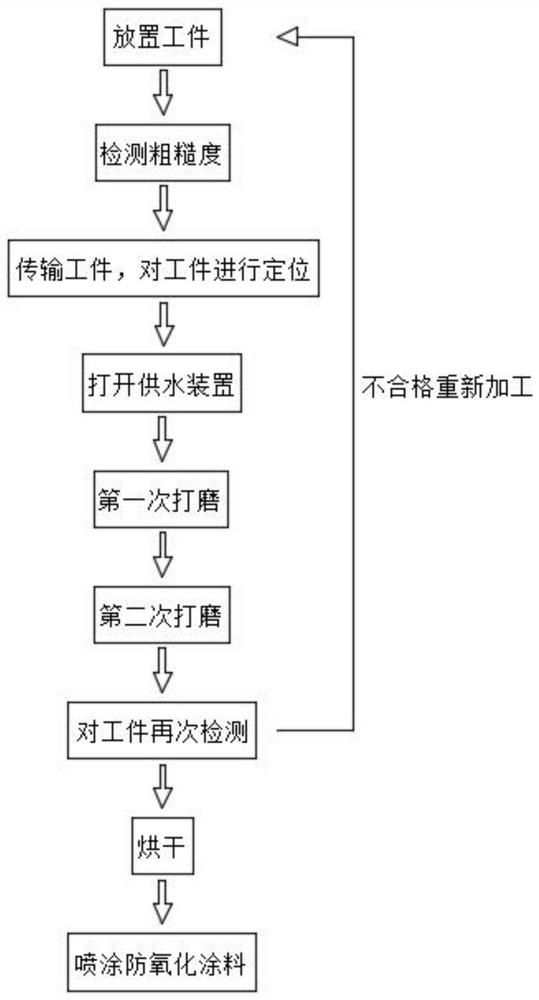

Image

Examples

Embodiment 1

[0053] (1) A rust-removing and polishing method for a copper target assembly, the rust-removing and polishing method comprises: using a polishing medium to sequentially perform rust surface polishing and texture polishing on the rust surface of the copper target assembly; The surface roughness Ra≤0.8μm; the texture grinding starts from the center point of the rusted surface.

[0054] (2) The sanding medium includes velvet sandpaper and scouring pad.

[0055] (3) The rust surface is polished by using back velvet sandpaper.

[0056] (4) The texture polishing is performed by using a scouring pad.

[0057] (5) Before the sanding treatment, masking treatment is performed on the non-grinding surface.

[0058] (6) The masking treatment is to mask the non-polished surface with an adhesive tape.

[0059] (7) The backing plate in the target assembly should be placed on the fixture before grinding.

[0060] (8) A cleaning cloth is arranged between the back plate and the fixture.

[...

Embodiment 2

[0064] (1) A method for grinding the weld seam of a cold-rolled stainless steel welded pipe. The grinding method is to use a grinding wheel whose sand density on the grinding surface gradually increases in the advancing direction of the weld seam to grind the weld seam in three steps. The grinding wheel used in the third grinding process in the advancing direction is at an angle of 10-15 degrees with the advancing direction of the weld; the grinding wheels used in the first two grinding processes in the three processes are 180 in turn. Grinding wheel and No. 180 grinding wheel, the grinding wheel used in the third grinding process is No. 320 grinding wheel.

[0065] (2) The grinding wheel used in the first two grinding processes in the advancing direction of the welding seam is at an angle of 45 degrees with the advancing direction of the welding seam, and the grinding wheel used in the first two grinding processes is advancing with the welding seam. The 45-degree angle formed...

Embodiment 3

[0067] (1) A method for grinding the weld seam of a cold-rolled stainless steel welded pipe. The grinding method is to use a grinding wheel whose sand density on the grinding surface gradually increases in the advancing direction of the weld seam to grind the weld seam in three steps. The grinding wheel used in the third grinding process in the advancing direction is at an angle of 10-15 degrees to the advancing direction of the weld.

[0068] (2) The grinding wheel used in the first two grinding processes in the advancing direction of the welding seam is at an angle of 45 degrees with the advancing direction of the welding seam, and the grinding wheel used in the first two grinding processes is advancing with the welding seam. The 45-degree angle formed between the directions is alternately distributed with different yaw directions.

[0069] (3) The grinding wheels used in the first two grinding processes are No. 180 grinding wheels, No. 180 grinding wheels and No. 180 grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com