Mineral dressing technique for low ore grade iron ore and mineral dressing equipment thereof

A kind of mineral processing equipment and iron ore technology, which is applied in the field of low-grade iron ore mineral processing technology and its mineral processing equipment, can solve the problems of low productivity, high cost, and inability to obtain economic benefits, etc., and achieve long service life, reduce load, and maintain The effect of simple and easy work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described below in conjunction with the drawings.

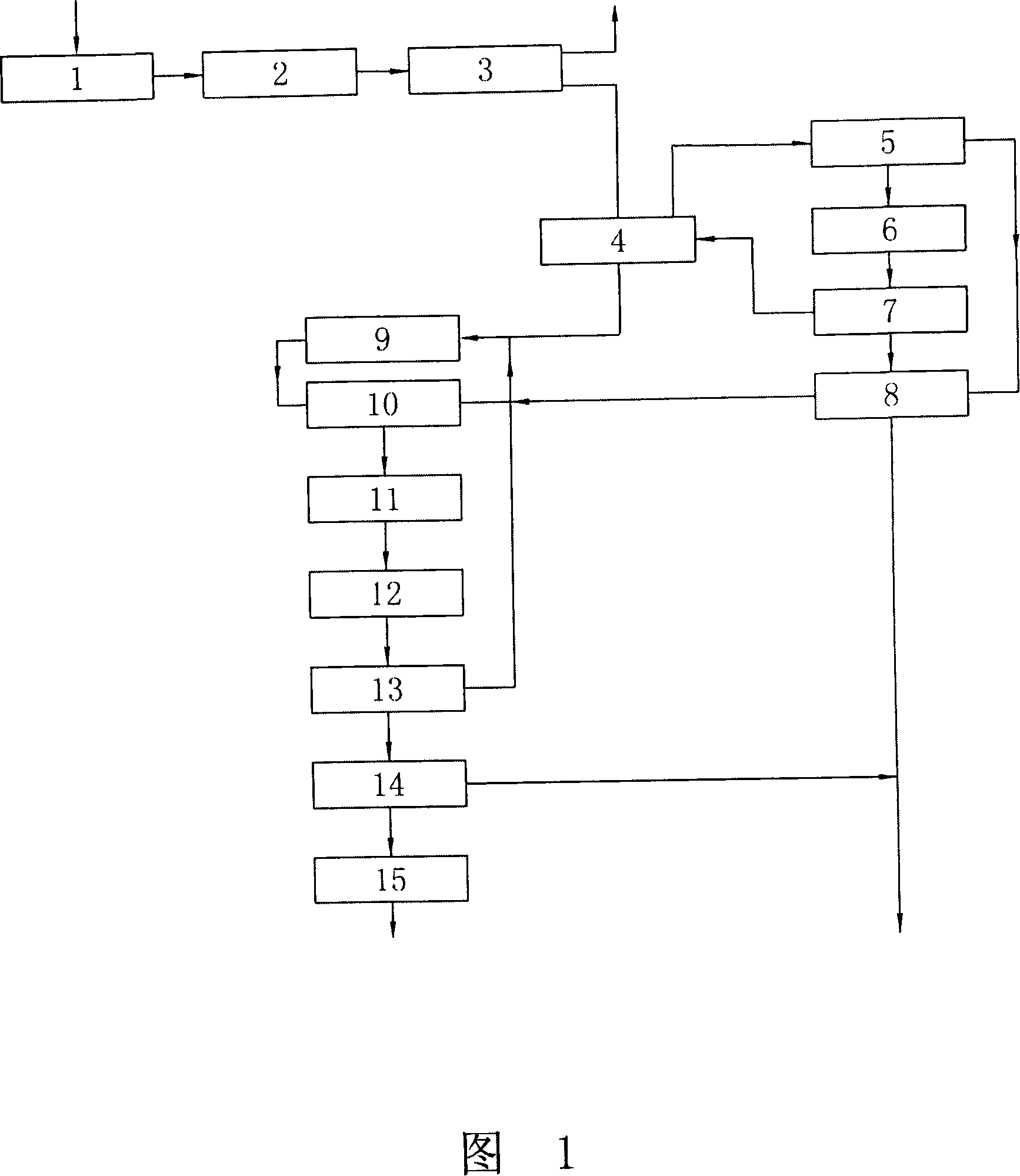

[0034] As shown in Figure 1, the low-grade iron ore beneficiation process according to the present invention includes coarse crushing, primary fine crushing, dry separation and screening, ball milling, material distribution machine, magnetic separation, high-frequency screening, and filtration. It is characterized by including the following steps:

[0035] 1) The mineral material sieved by the coarse crushing, primary fine crushing, and dry separation screening machine 3 is sent from the storage bin 4 to the secondary screening machine 5 through the conveyor belt for secondary screening.

[0036] 2) The coarse ore screened by the secondary screening machine 5 is sent to the wet fine crusher 6 for secondary fine crushing, and the fine material screened out is sent to the wet coarse classifier 8 for wet roughing.

[0037] 3) The secondary finely crushed mineral materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com