Construction waste treatment device

A processing device and technology for construction waste, applied in the fields of grain processing, construction waste recycling, recycling technology, etc., can solve the problems of large occupied space, large volume, and increase the cost of construction waste transportation, and achieve good efficiency and continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

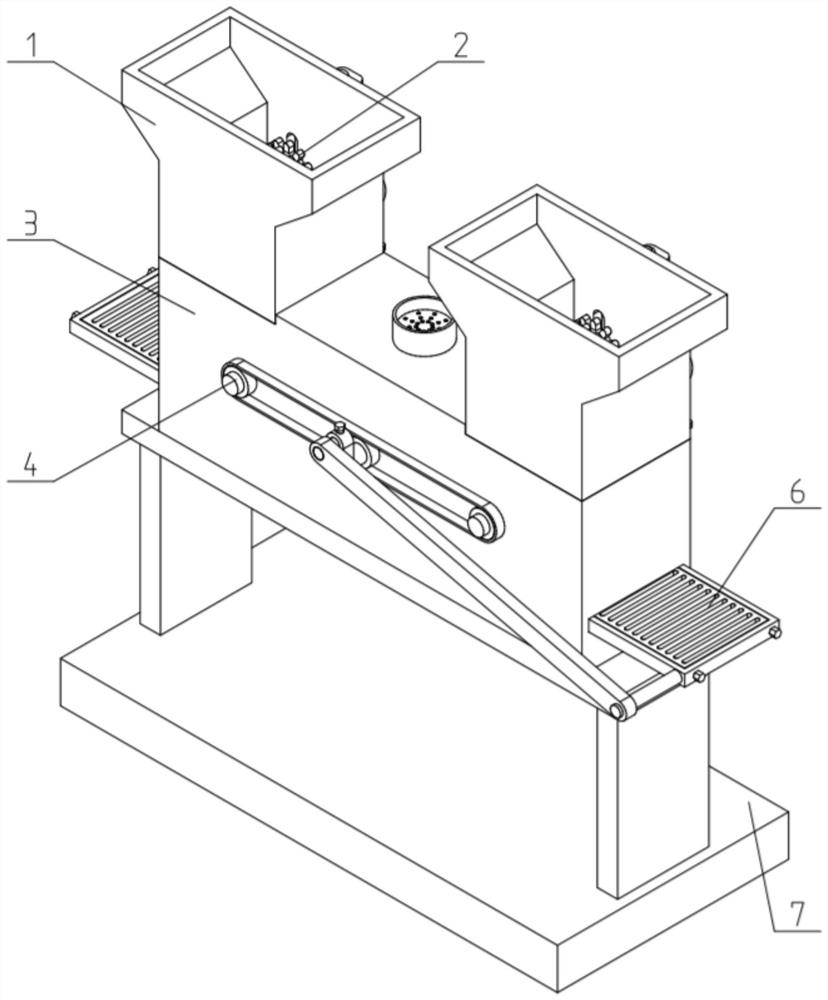

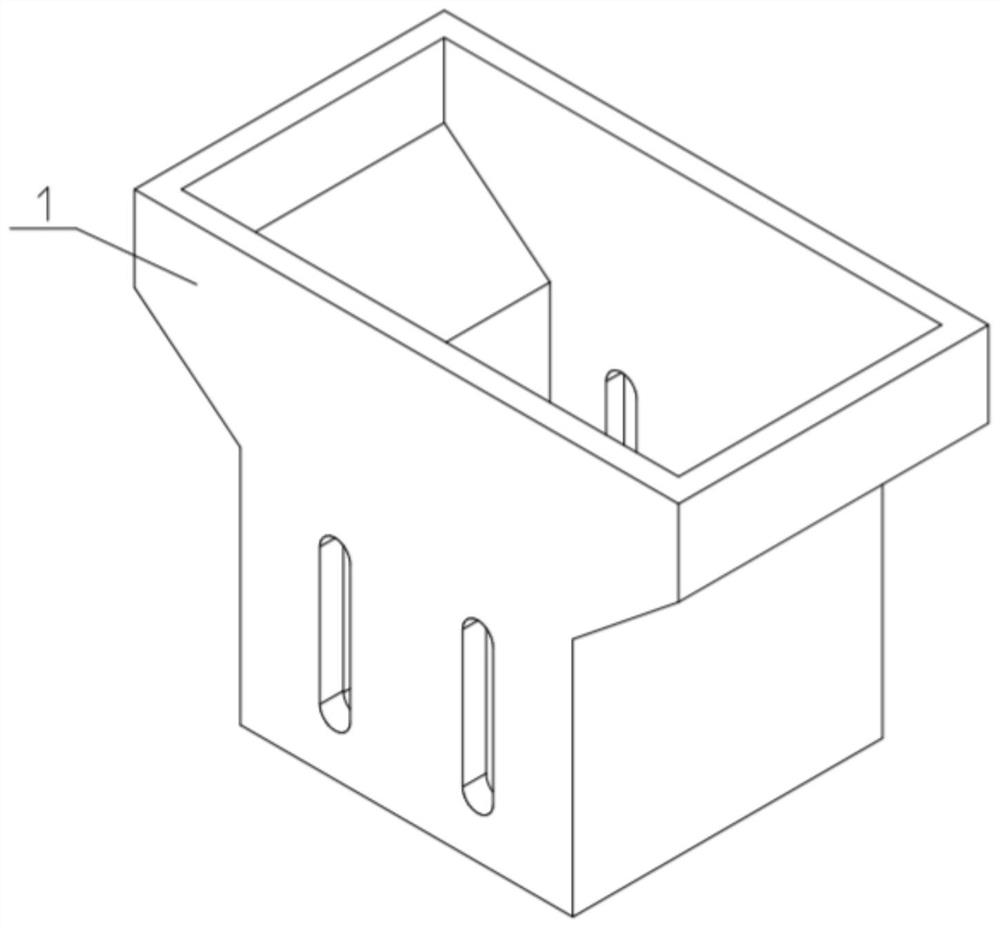

[0038] Such as Figure 1-11 As shown, the construction waste treatment device includes a feed crushing box 1, a crushing and crushing mechanism 2, a mixing and crushing box 3, a stirring and crushing mechanism 4, a driving mechanism 5, a screening device 6 and a frame 7. The feed crushing box 1 is provided with two, the two feed crushing boxes 1 are relatively fixedly connected to the two ends of the top surface of the mixing and crushing box 3; the mixing and crushing boxes 3 are fixedly connected to the frame 7; Said feed crushing box 1 is respectively connected with one of said crushing and crushing mechanism 2; said mixing and crushing box 3 is connected with said stirring and crushing mechanism 4; said driving mechanism 5 is connected to said mixing and crushing box 3; The driving mechanism 5 is drivingly connected to the stirring and crushing mechanism 4 and the two crushing and crushing mechanisms 2; the stirring and crushing mechanism 4 is drivingly connected to the sie...

specific Embodiment approach 2

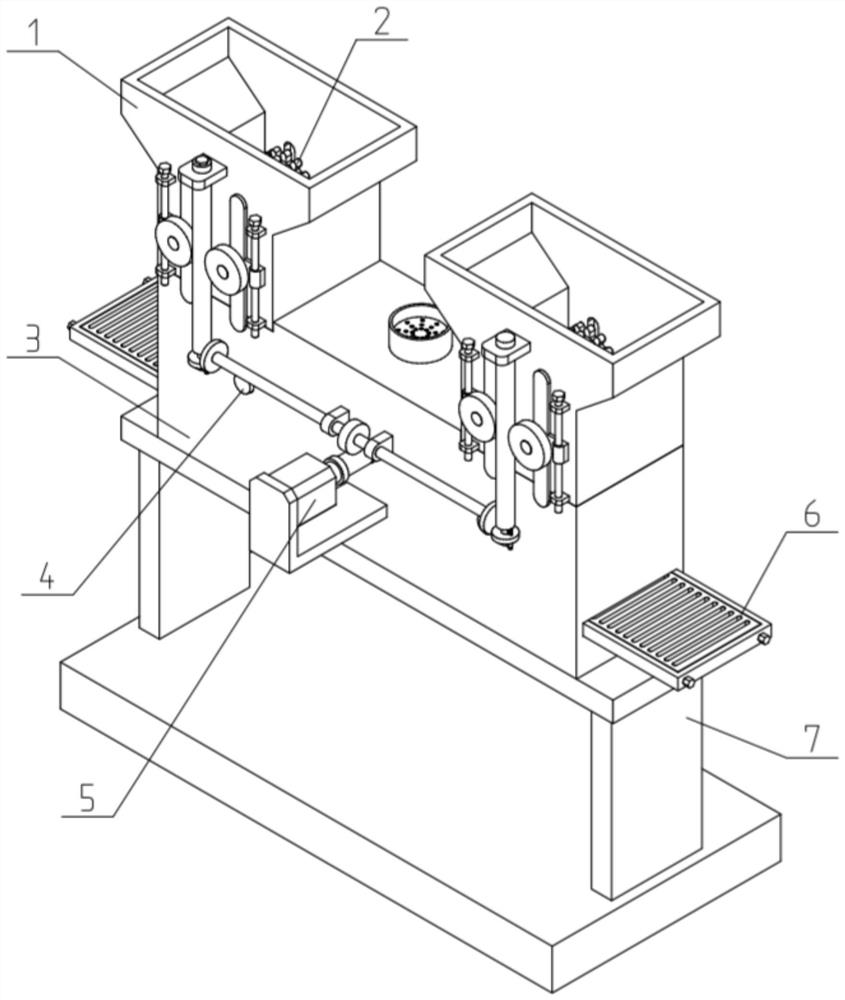

[0040] Such as Figure 1-11 As shown, the driving mechanism 5 includes a servo motor 501, a first worm 502, a first worm gear 503, a first rotating shaft 504, a first shaft seat 505 and a friction transmission wheel 506; the servo motor 501 is fixedly connected to On the hybrid crushing box 3; the output shaft of the servo motor 501 is connected to the first worm 502 through a coupling; the first worm 502 is connected to the first worm gear 503 by meshing transmission; the first worm gear 503 It is fixedly connected to the middle of the first rotating shaft 504; the first rotating shaft 504 is rotatably connected to the two first shaft seats 505; the first shaft seat 505 is fixedly connected to the mixing and crushing box 3 The two ends of the first rotating shaft 504 are respectively fixedly connected to one of the friction transmission wheels 506; the two friction transmission wheels 506 are respectively connected to the grinding and crushing mechanism 2 by friction transmiss...

specific Embodiment approach 3

[0042] Such as Figure 1-11 As shown, the grinding and crushing mechanism 2 includes a friction linkage wheel 201, a second worm 202, a cross seat 203, a second worm wheel 204, a rotating shaft 205, a bearing bracket 206 and a grinding roller 207; the friction transmission wheel 506 is vertical Friction transmission is connected to the friction linkage wheel 201; the friction linkage wheel 201 is connected to the lower end of the second worm 202; the upper end of the second worm 202 is rotatably fitted on the cross seat 203; the cross seat 203 is fixedly connected On the feed crushing box 1; the second worm 202 is meshed and driven to connect the two second worm wheels 204; the two second worm wheels 204 are respectively fixedly connected to one end of the two rotating shafts 205; The two rotating shafts 205 are slidably fitted in the groove-shaped slides and groove-shaped through holes on the inner side of the feed crushing box 1; the two rotating shafts 205 are respectively r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com