Mine ore material magnetic separation and distribution equipment

A magnetic separation and mining technology, applied in the field of magnetic separation and material separation equipment, can solve the problems of iron powder screening and removal, affecting the production quality of ore materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

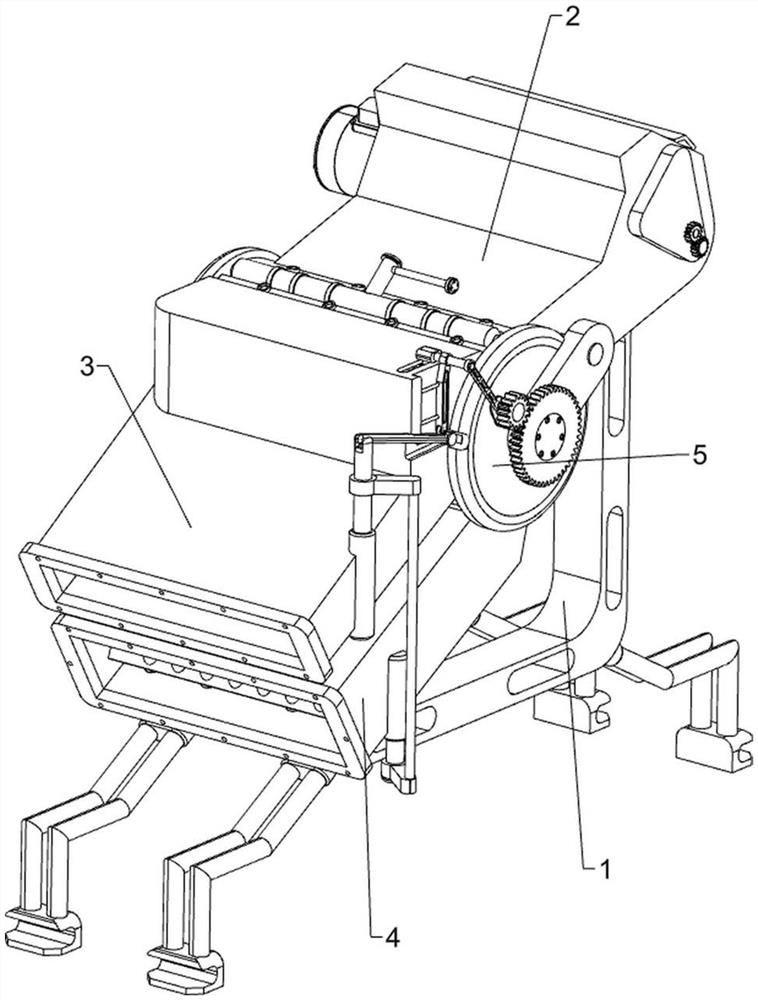

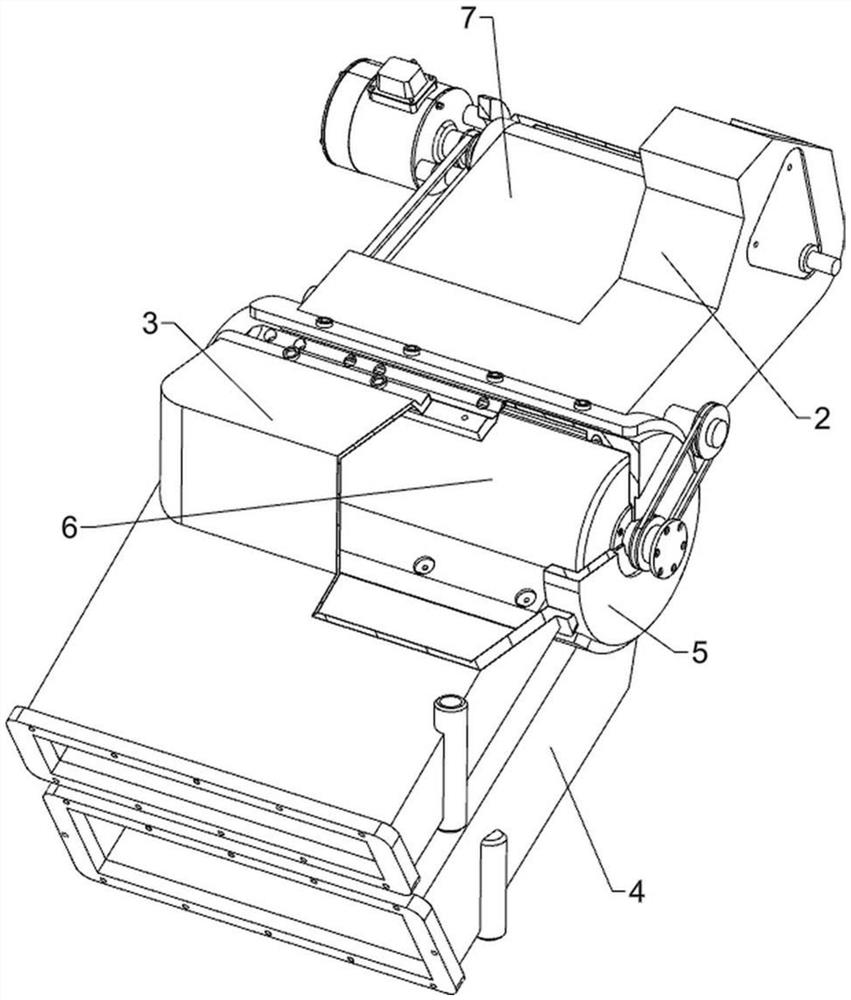

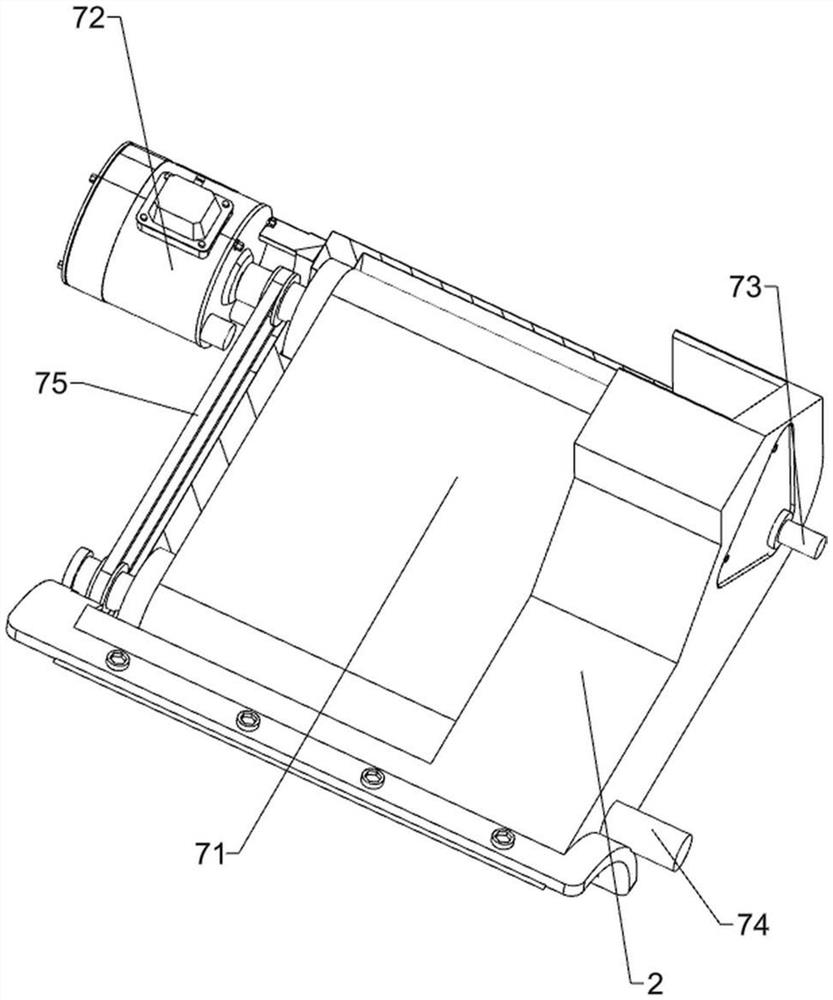

[0040] A magnetic separation and distribution equipment for mine minerals, such as Figure 1-Figure 5 As shown, it includes a supporting chassis 1, a feeding square pipe 2, a first discharging pipe 3, a second discharging pipe 4, a screening cylinder 5, a screening roller 6, a feeding mechanism 7 and a material distribution mechanism 8 , the upper right part of the support chassis 1 is connected with a feeding square tube 2, the left part of the feeding square tube 2 is connected with a sieve cylinder 5 by means of bolt connection, and the upper side of the left part of the sieve cylinder 5 is connected with a first The discharge pipe 3, the lower left side of the screen cylinder 5 is connected with a second discharge pipe 4, the feeding square pipe 2 is connected with a feeding mechanism 7, and the feeding mechanism 7 can realize the discharge of mineral materials, feeding A material distribution mechanism 8 is connected between the mechanism 7 and the screening cylinder 5. T...

Embodiment 2

[0045] On the basis of Example 1, as Figure 6-Figure 10 As shown, it also includes a cleaning mechanism 9. The cleaning mechanism 9 includes a drive toothed disc 91, a first driven gear 92, a rotating circular seat 93, a first hinge rod 94, a traverse crossbar 95, and a second hinge rod. 96. The cleaning brush 97, the fixed horizontal frame 98 and the fixed short rod 99, the front part of the fixed short shaft 81 is fixedly connected with a drive toothed plate 91, and the upper left side of the front part of the screen cylinder 5 is connected with a rotating round seat 93 in a rotary manner, and the rotating The front part of the round seat 93 is fixed with a first driven gear 92, the first driven gear 92 is meshed with the driving gear plate 91, the middle part of the rotating round seat 93 is rotatably connected with a first hinge rod 94, and the upper part of the first discharge pipe 3 The right front side is slidably connected with a traverse bar 95, the front part of the...

Embodiment 3

[0052] On the basis of Example 1 and Example 2, as Figure 13 and Figure 18 As shown, it also includes a blowing mechanism 12, the blowing mechanism 12 includes a blowing round pipe 121 and an air inlet pipe 122, and a blowing round pipe 121 is embedded in the middle of the upper part of the screen cylinder 5, and the blowing round pipe 121 can be The material is blown off, and the air inlet pipe 122 is connected to the middle of the air blowing round pipe 121 .

[0053] A cover 123 is also included, and a cover 123 is threadedly placed at the front of the air intake pipe 122 .

[0054] First, the operator opens the cover 123 to connect the air inlet pipe 122 to an external fan. When people use the device, the air blowing pipe 121 blows air to the screen cylinder 5, and then blows the unadsorbed substances into the second discharge pipe 4. , when the device is not needed, stop externally connecting the air inlet pipe 122, and then cover the cover 123, so that the mineral scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com