Screening equipment based on comprehensive utilization of energy waste

A technology for screening equipment and waste, applied in the fields of sieves, solid separation, chemical instruments and methods, etc., can solve the problems of low screening efficiency, poor user satisfaction, improve screening efficiency, etc., to ensure smoothness and effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

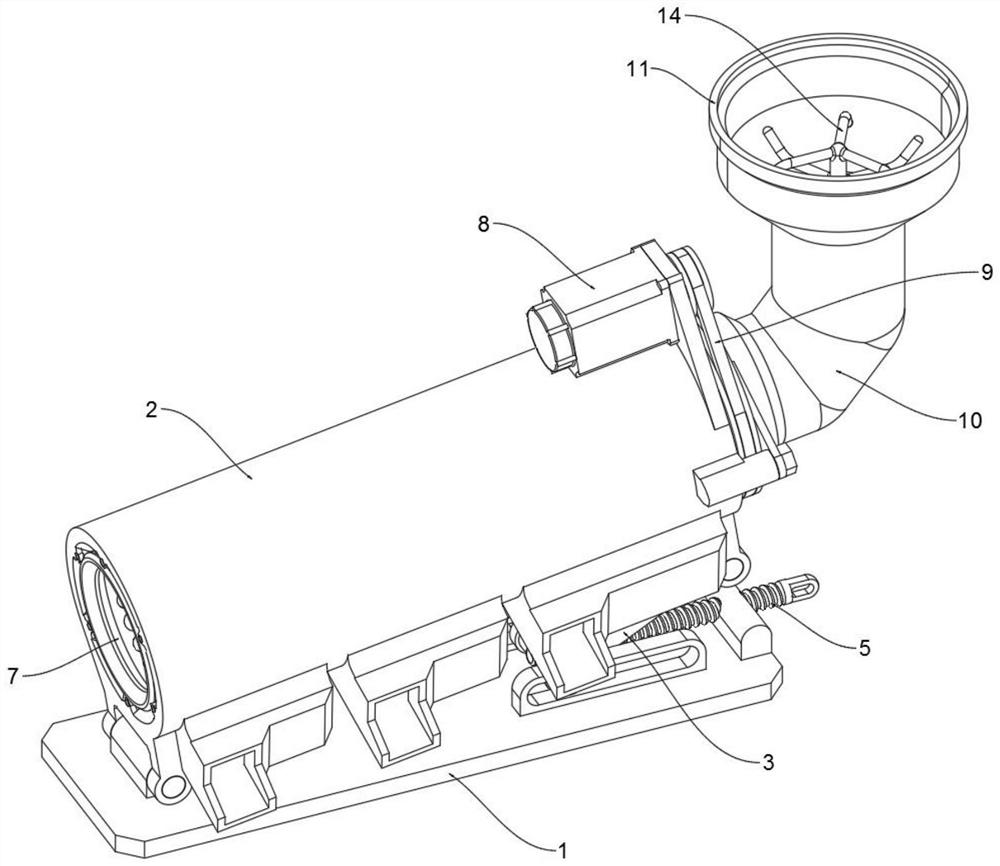

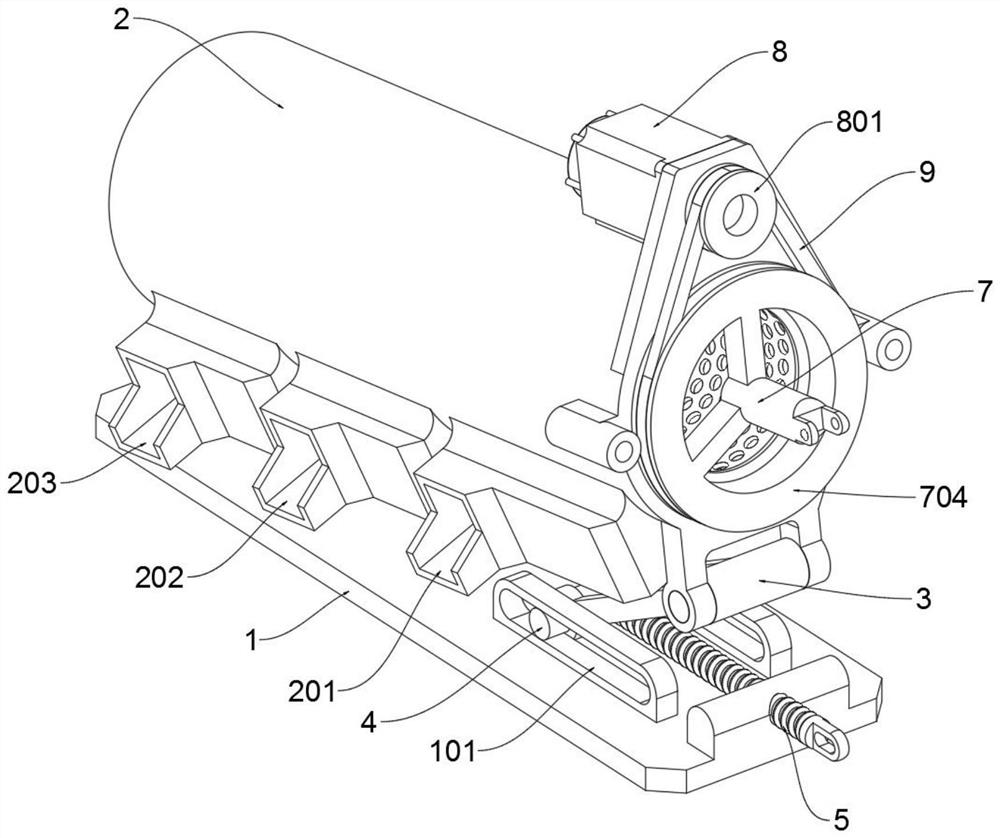

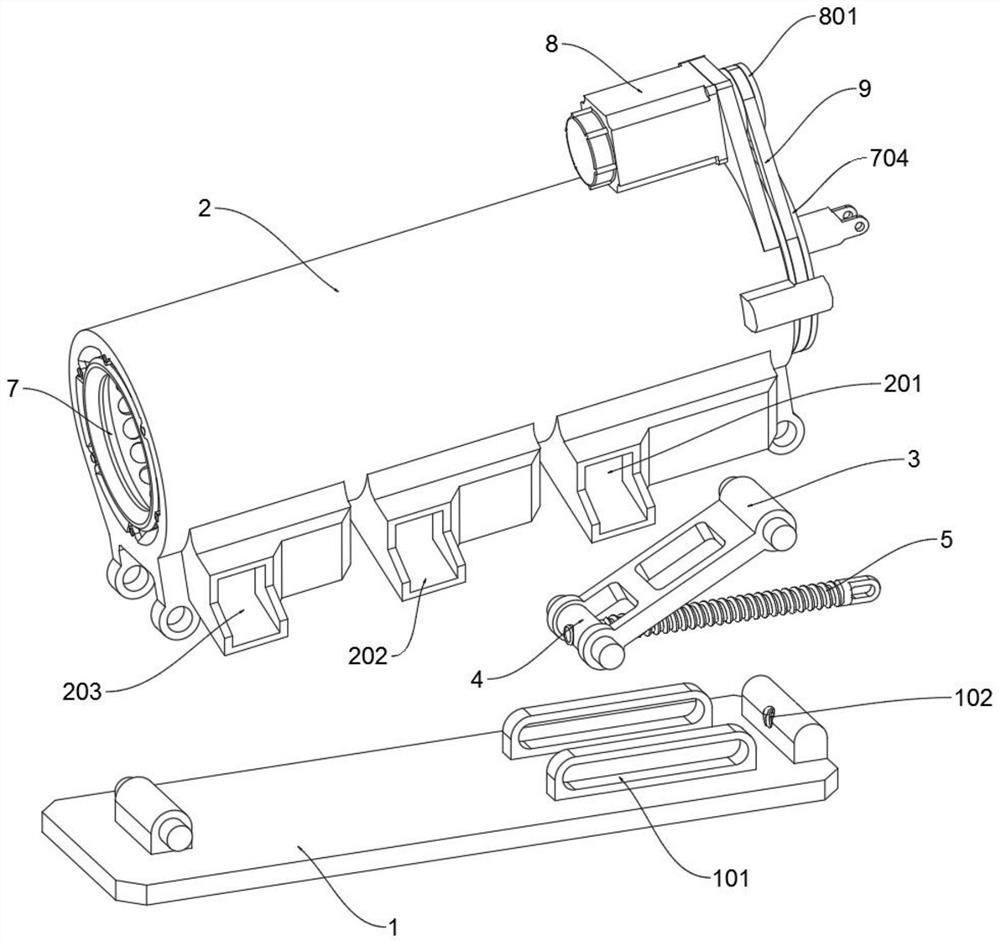

[0033] Please refer to Figure 1 to Figure 8 :

[0034] The present invention proposes a screening device based on comprehensive utilization of energy waste, comprising: a base 1; an outer cylinder 2 is installed on the top of the base 1, and the rear end of the outer cylinder 2 is connected to a support frame 3, and the bottom end of the support frame 3 passes through a movable shaft 4 Connected with the base 1; the screening tube 7 is installed inside the outer tube 2, and the rear end of the screening tube 7 is provided with a driven pulley 704, and the driven pulley 704 is located outside the rear end of the outer tube 2; A set of rollers 6, the screening drum 7 is rotatably connected to the interior of the outer drum 2, the roller 6 is in rolling contact with the screening drum 7, and the screening drum 7 is composed of a fine screen drum 701, a medium screen drum 702 and a coarse screen drum 703, and the bottom of the outer drum 2 is opened in turn There are fine discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com