A negative pressure sieve equipment for the preparation of concrete composite admixture

A composite admixture and concrete technology, which is applied in the direction of sieving, separating solids from solids with airflow, solid separation, etc., to achieve the effects of not easy to leak, ensure the working environment, and facilitate screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

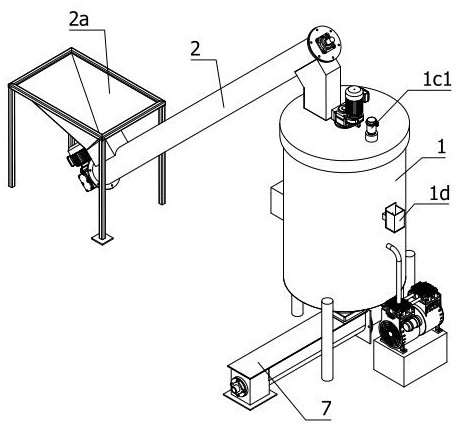

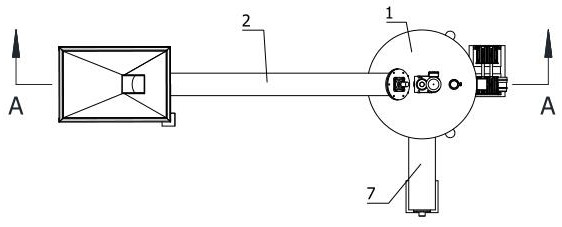

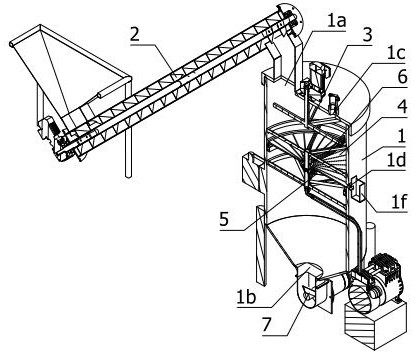

[0041] refer to image 3 Shown, a kind of negative pressure screen equipment for the preparation of concrete composite admixture includes:

[0042] Screening tank 1, the top and bottom end are respectively provided with the first feed port 1a and the first discharge port 1b, the top of the screening tank 1 is also provided with an air inlet pipe 1c for balancing internal and external pressure, the peripheral surface of the screening tank 1 There is also a miscellaneous outlet 1d for discharging large particle admixtures;

[0043] The inclined screw feeder 2 is arranged on one side of the screening tank 1 and the top is communicated with the first feeding port 1a;

[0044] The bulk material device 3, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com