Building gravel screening machine having anti-blocking function

A sieving machine and sand and gravel technology, which is applied in the direction of sieving, solid separation, and separation of solids from solids with air flow, etc. It can solve the problem that the sieve plate is easy to block and cannot sieve sand and gravel with different particle sizes at one time. , Low screening efficiency and other problems, to achieve the effect of reducing manual labor, high screening efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

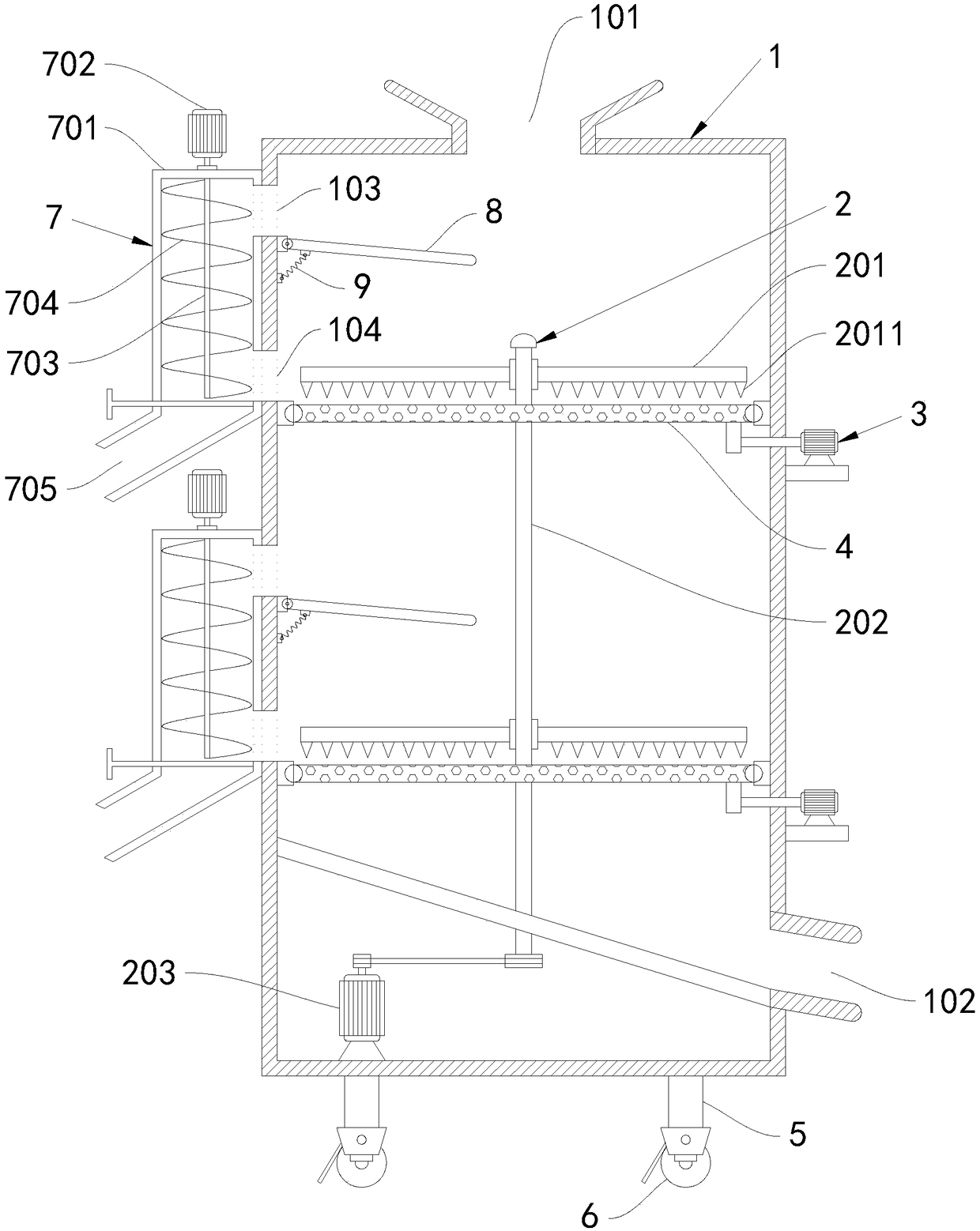

[0033] like figure 1 As shown, this embodiment provides a construction sand and gravel screening machine with anti-blocking function, including a box body, the box body is cylindrical, the top of the box body is provided with a feeding port in the middle, and the side of the lower part of the box body is provided with At the discharge port, there are scraper assembly and 2 sieve plates in the box. The sieve plates are set horizontally and hinged with the side wall of the box body. Multiple sieve plate holes are evenly distributed on the sieve plate. The size of the sieve plate hole is different. The sieve plate hole of the upper sieve plate is larger than the sieve plate hole of the lower sieve plate. The scraper assembly includes a vertical first rotating shaft and a first drive motor to drive the first rotating shaft. The first rotating shaft is located in the box body. The middle of the two sieve plates passes through the middle of the two sieve plates respectively. The fir...

Embodiment 2

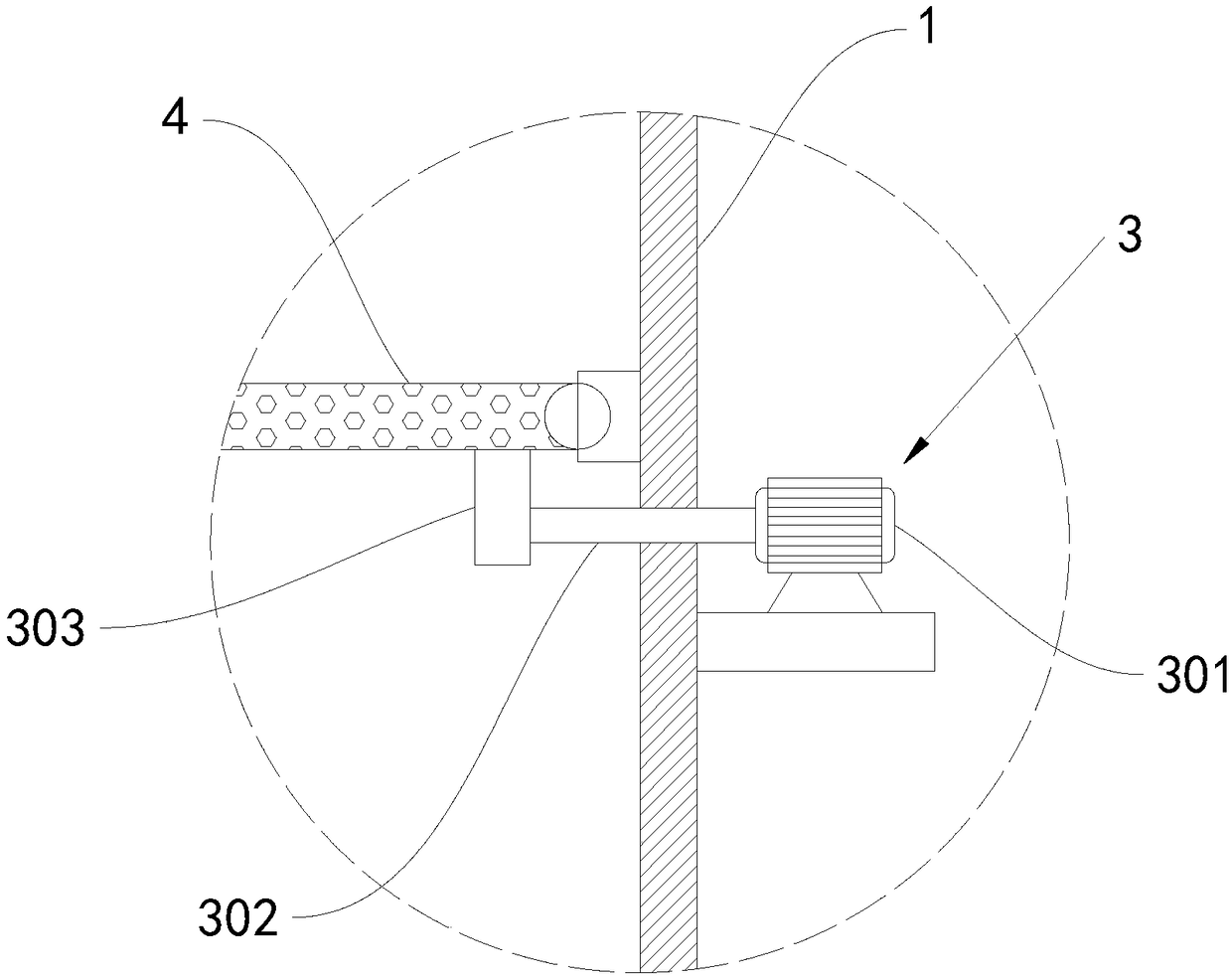

[0035] like figure 1 and figure 2 As shown, in order to further improve the screening efficiency of the sieve plate, this embodiment has made further improvements on the basis of embodiment 1, specifically, a vibrating mechanism is provided under the sieve plate, and the vibration includes a third rotating shaft arranged horizontally and a driving third The third driving motor that rotates the rotating shaft, the third driving motor is located outside the box body, the third rotating shaft crosses the side wall of the box body and is connected with the third driving motor, the third rotating shaft is set with a cam for hitting the sieve plate, through The vibrating mechanism is set under the sieve plate, which can continuously vibrate the sieve plate while sieving. First, it is easy to make the sand smaller than the aperture of the sieve plate fall from the sieve plate hole quickly, and second, it is easy to block the sand and stones that block the sieve plate hole. The sand...

Embodiment 3

[0037] like figure 1 and figure 2 As shown, this embodiment has been further improved on the basis of embodiment 2. Specifically, a material guide plate is welded on the inner wall of the box, and the end of the material guide plate connected to the inner wall of the box is located at the lower end surface of the circulation inlet. A material guide plate is set on the inner wall of the box. First, it can prolong the movement path of the sand and gravel coming out of the circulation inlet, so as to avoid excessive sand and gravel falling on the sieve plate at the same time to cause accumulation and affect the screening efficiency; second, the material guide plate The sand and gravel coming out of the circulation inlet can be made to fall near the middle of the sieve plate, and the sand and gravel coming out of the circulation inlet can be prevented from falling directly near the circulation outlet, so that the effect of repeated screening will be deteriorated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com