Patents

Literature

46results about How to "Achieve vibration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

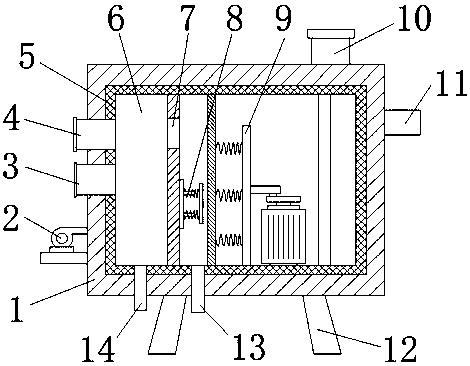

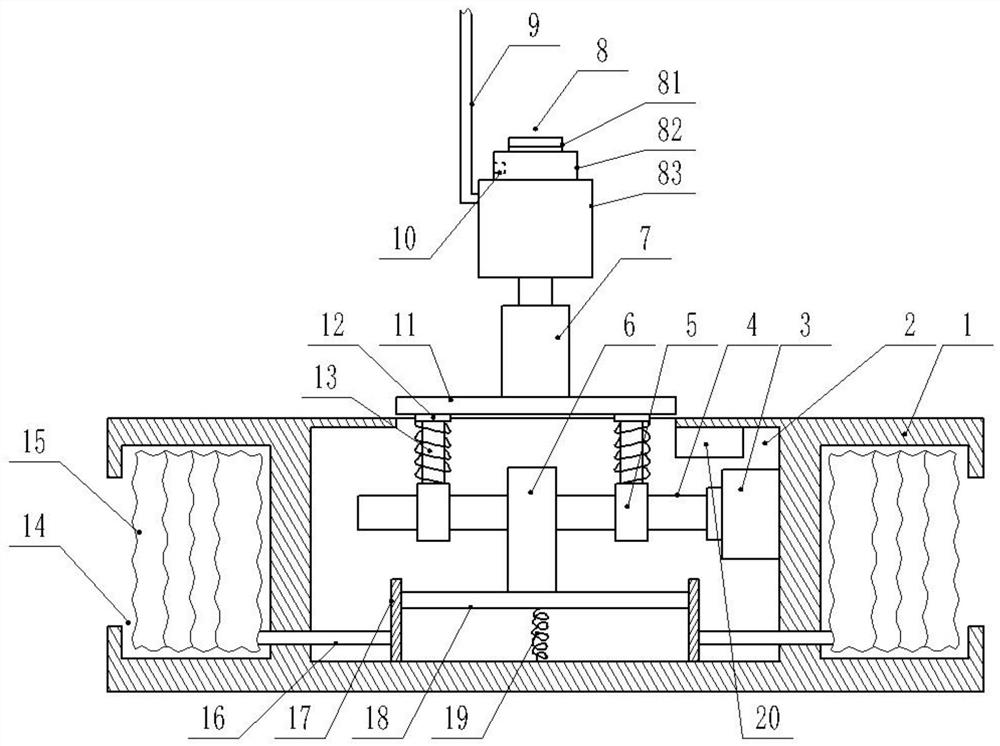

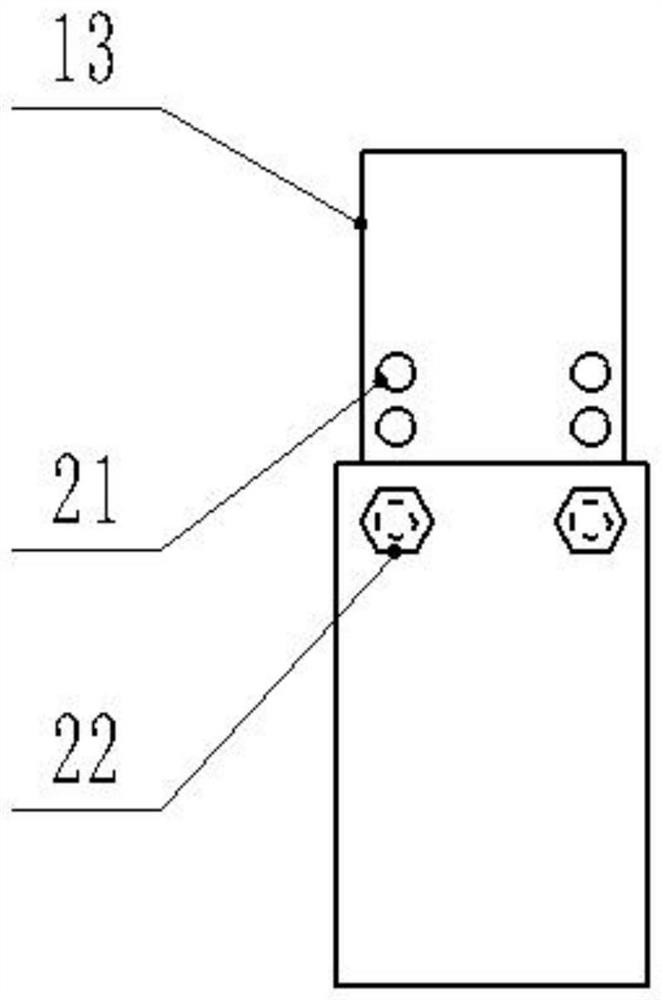

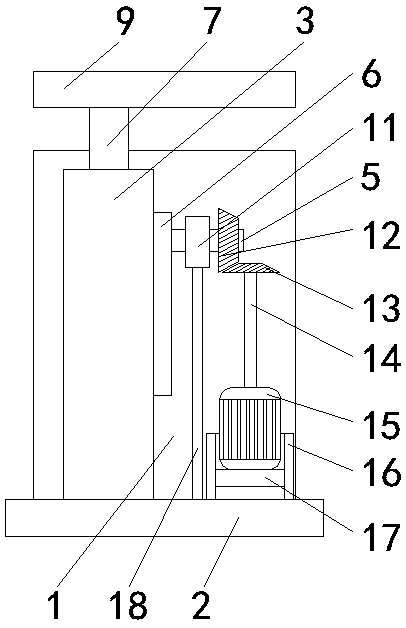

Device for martial arts single-leg balance force training

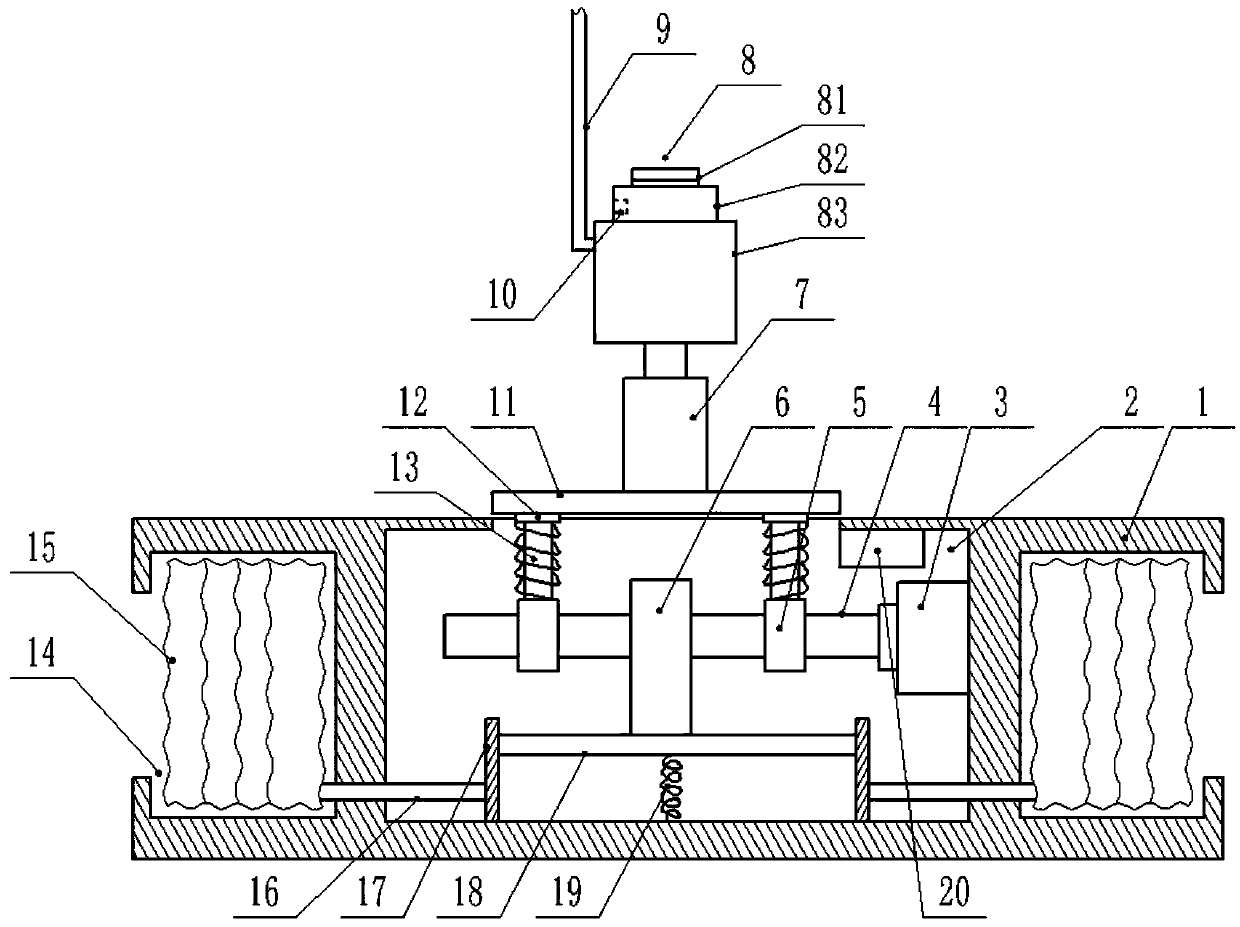

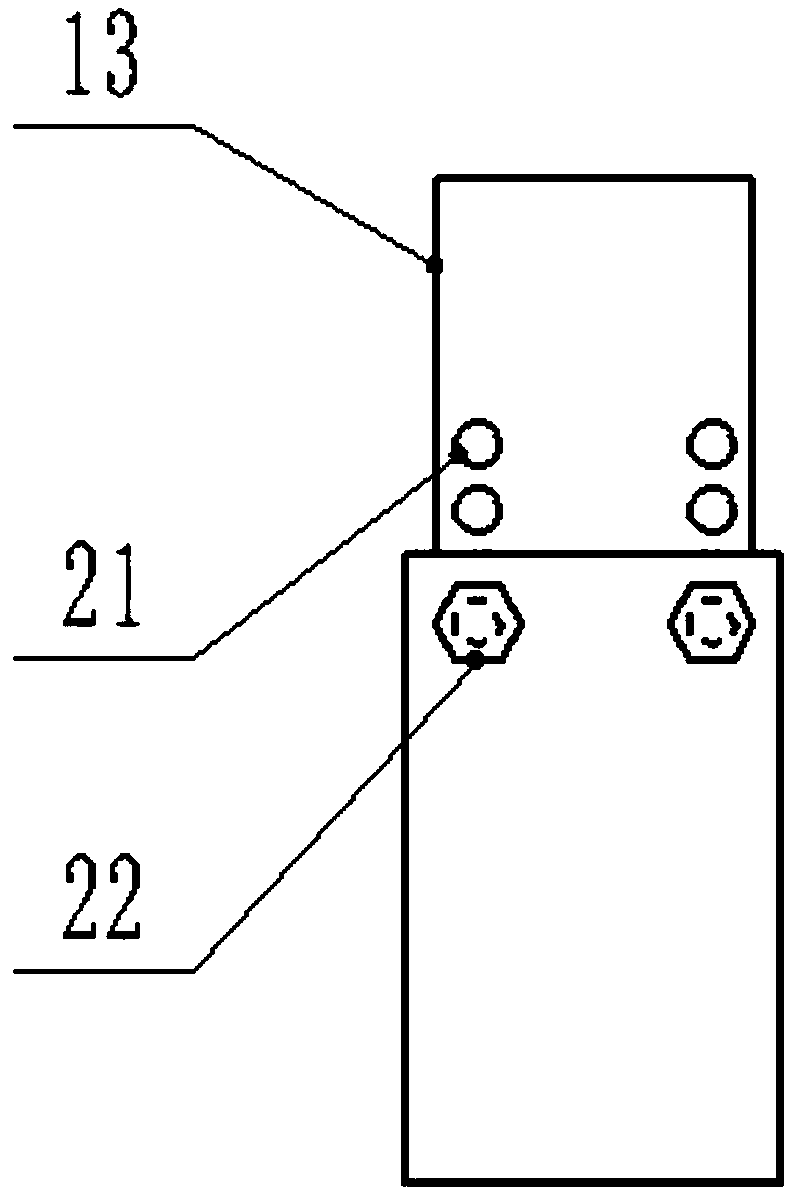

The invention belongs to the technical field of balance force training, and discloses a device for martial arts single-leg balance force training. The device comprises a bottom plate, the bottom plateis provided with a groove, a motor is installed in the groove, an output end of the motor is connected with a screw rod, the screw rod is in threaded connection with nuts, the top of each nut is fixedly provided with a connecting rod, each connecting rod is sleeved with a spring, the bottom of each spring is fixed on the corresponding connecting rod, a transverse plate is fixedly arranged at thetops of the springs, the connecting rods support the transverse plate in the free state of the springs, and the screw rod is fixedly provided with a cam for jacking the transverse plate from the connecting rods; an air cylinder is installed on the transverse plate, and an output end of the air cylinder is connected with a single-leg pile. The device additionally has a training function to meet therequirement for training difficulty of martial arts single-leg balance force.

Owner:JISHOU UNIVERSITY

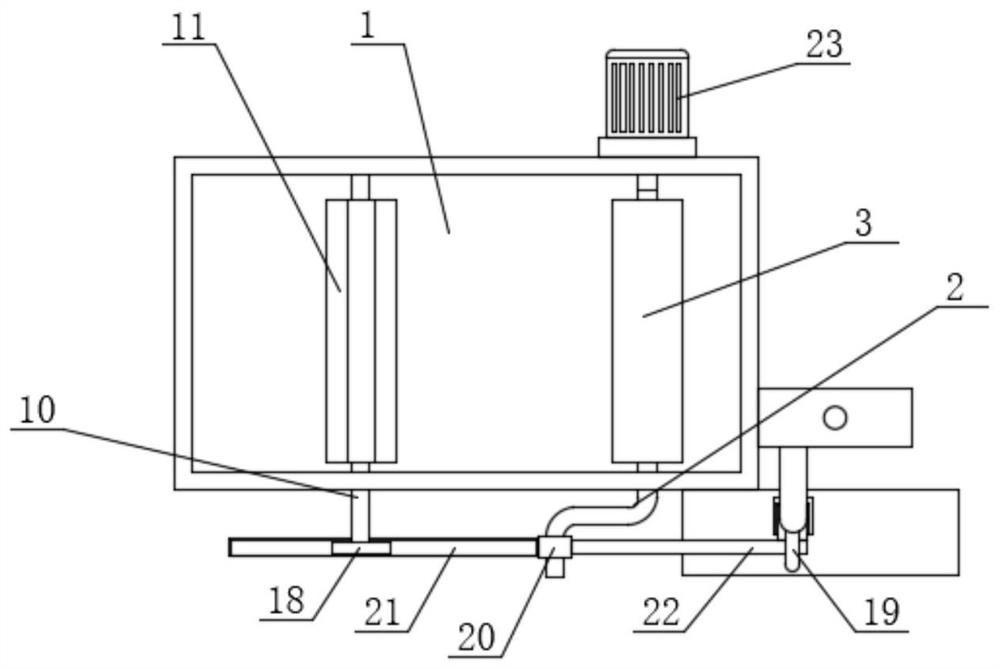

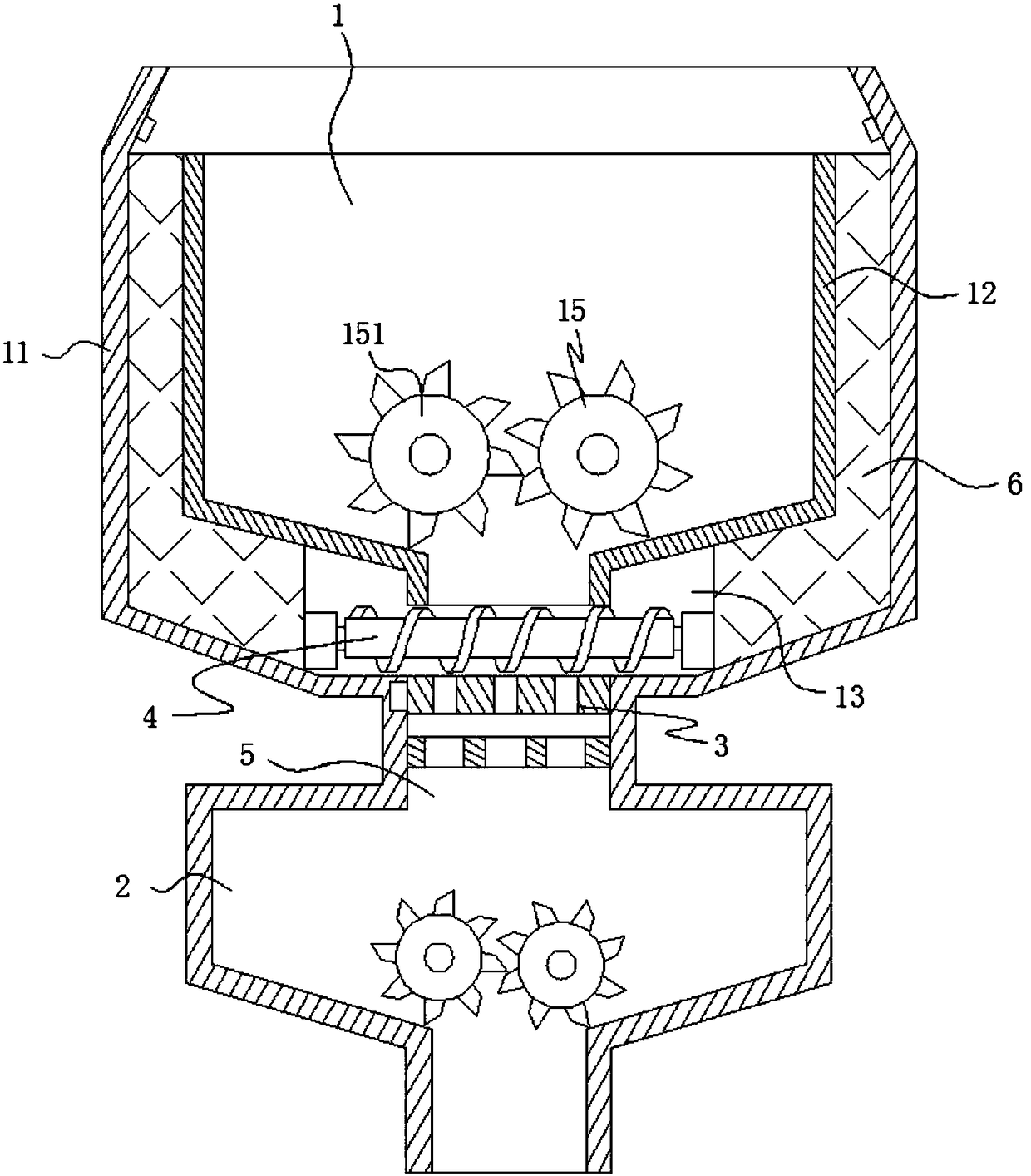

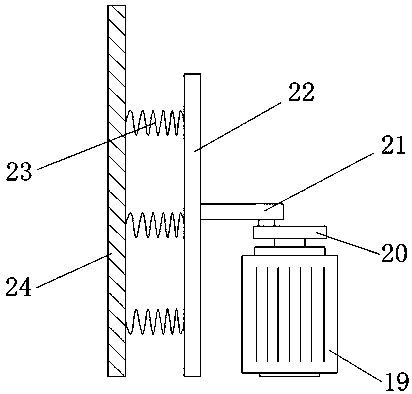

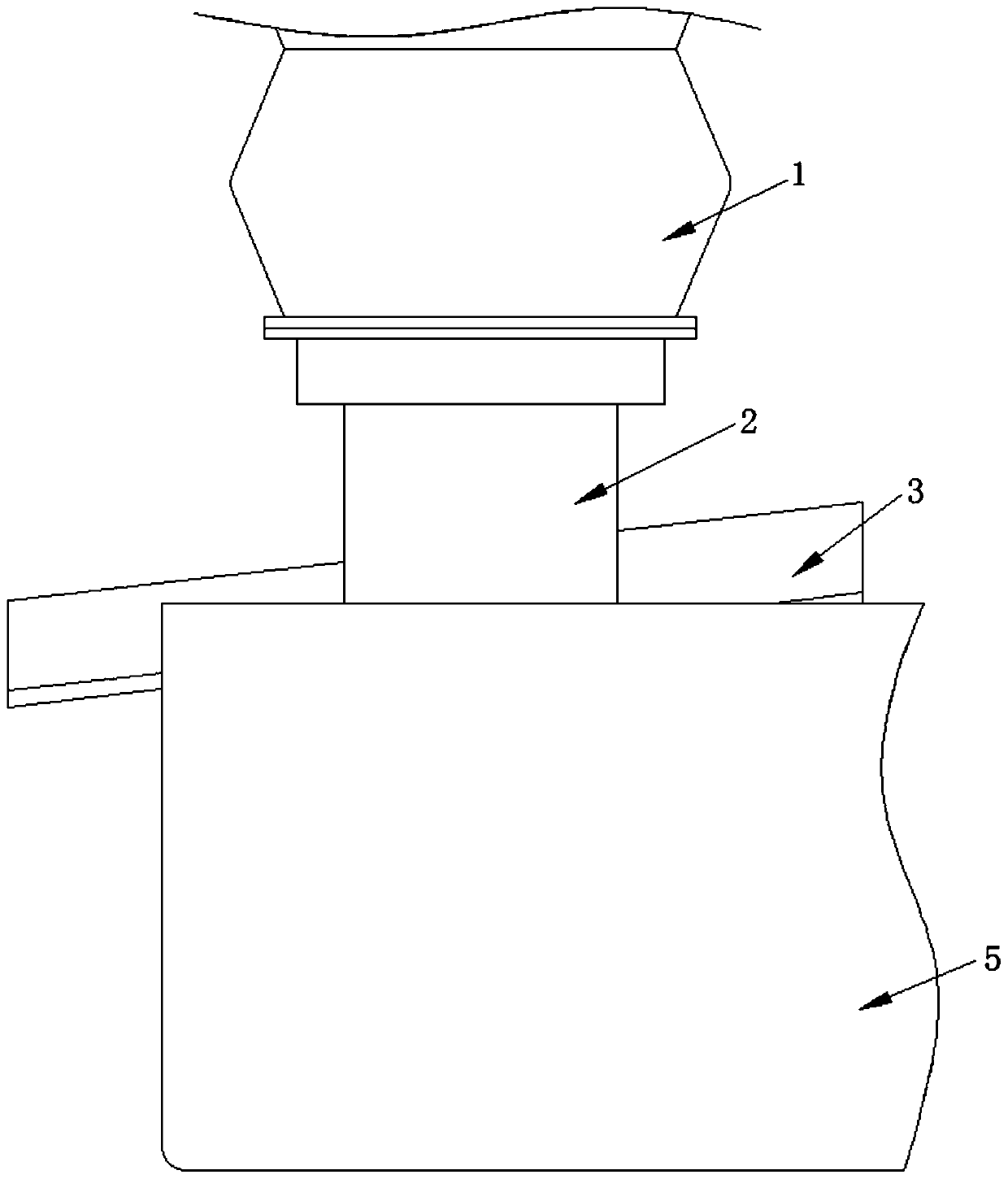

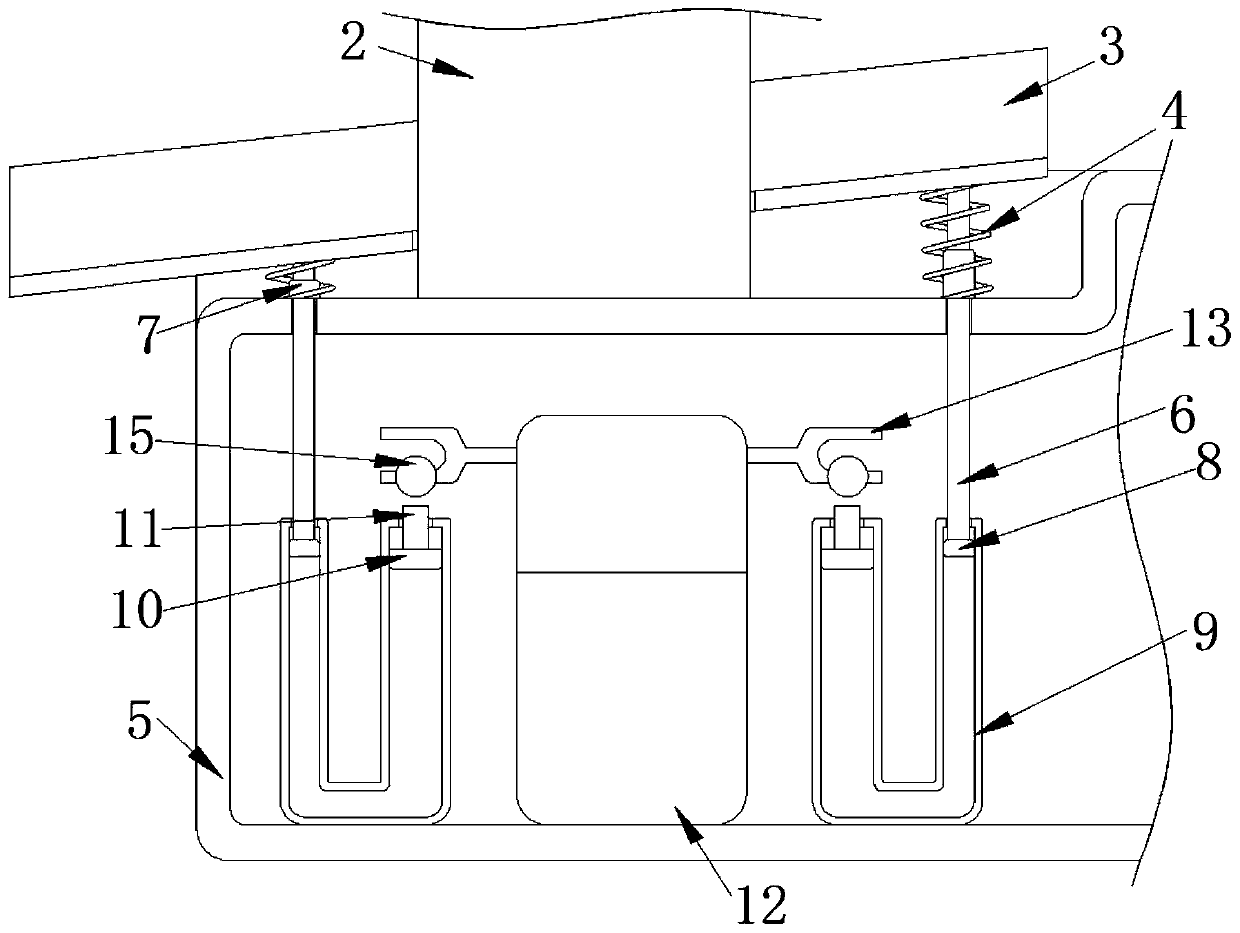

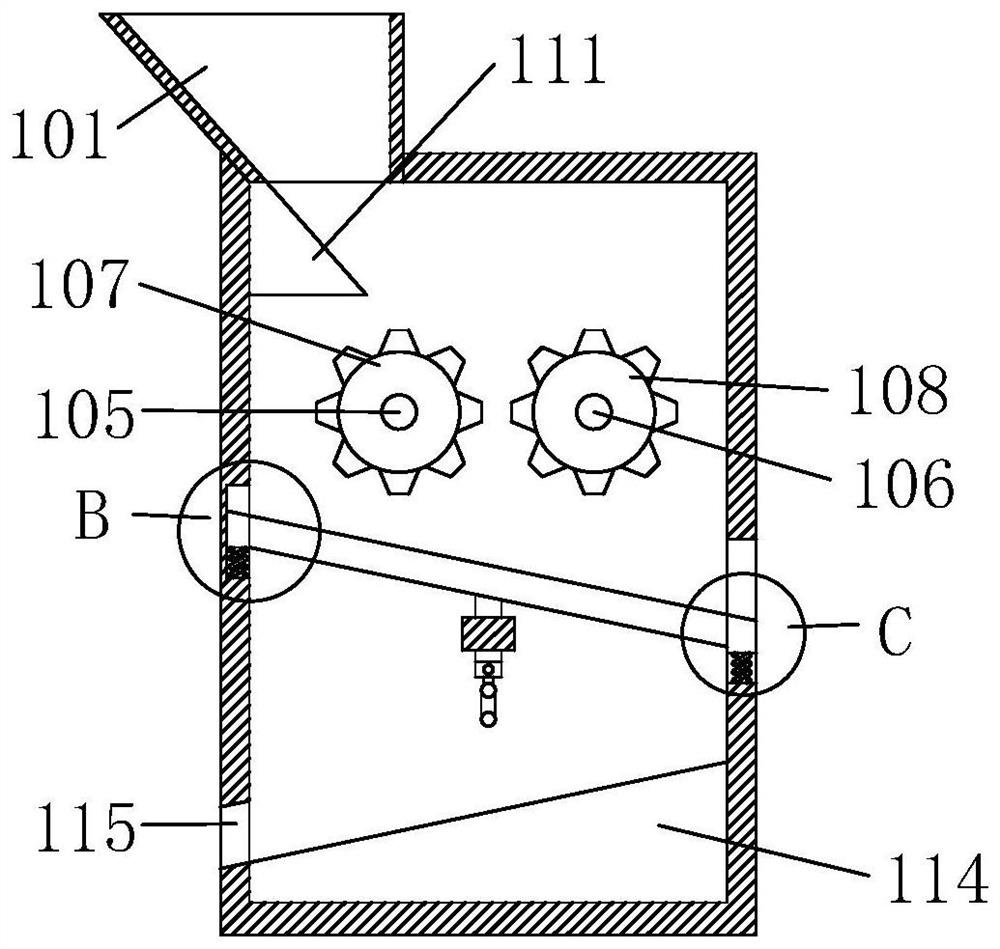

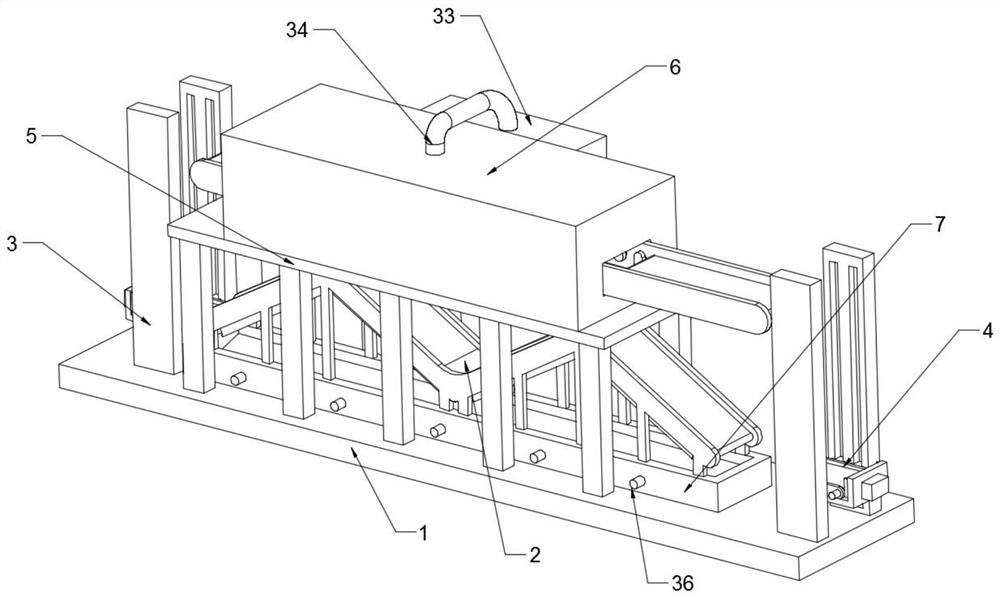

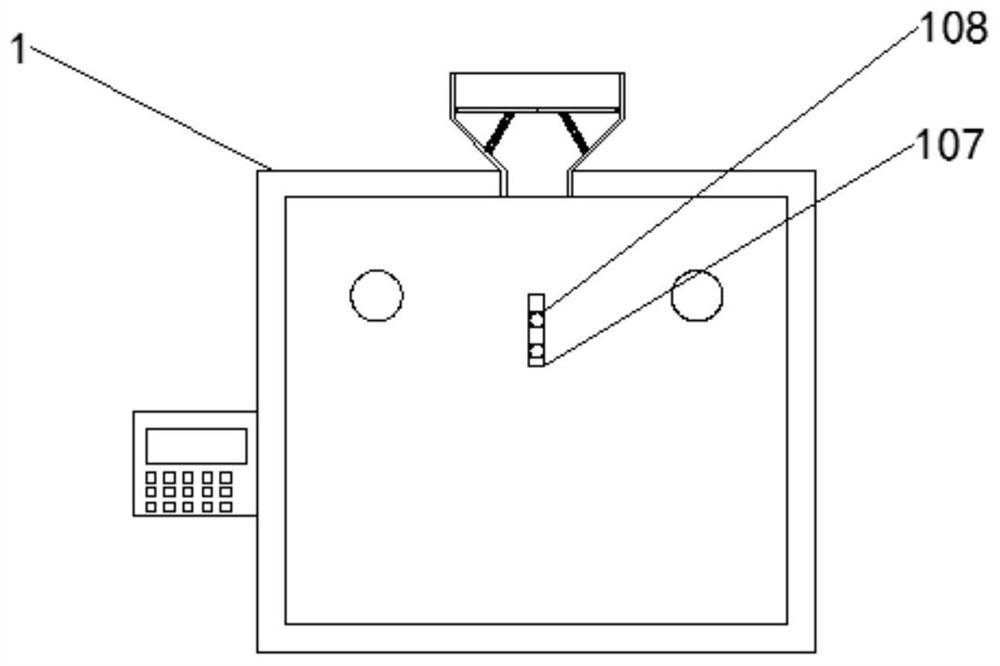

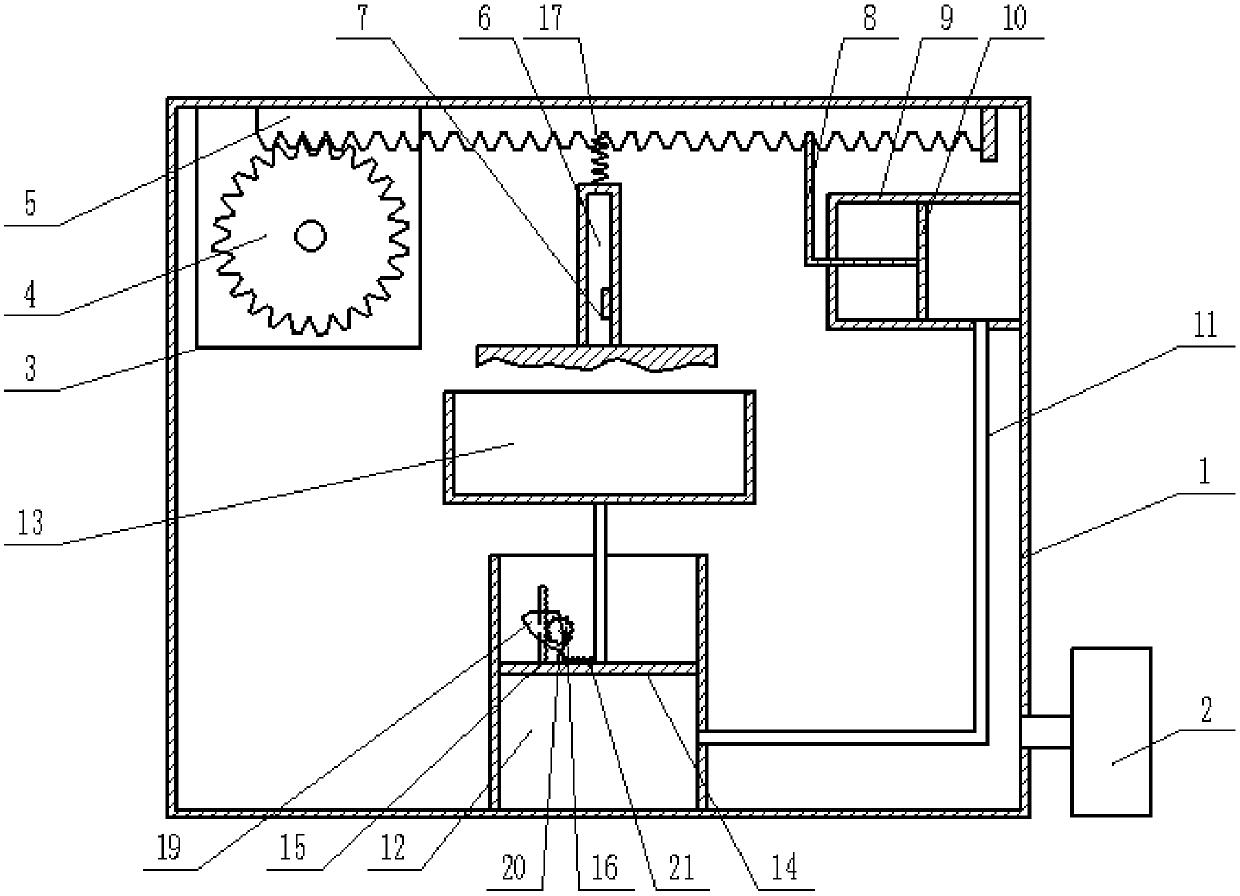

Waste recovery device for constructional engineering

ActiveCN114345455AAchieve vibration effectEasy to separateSievingConstruction waste recoveryArchitectural engineeringElectric machinery

The invention belongs to the field of building material recovery devices, particularly relates to a waste recovery device for constructional engineering, and aims to solve the problems that resources are wasted and the crushing effect is not ideal due to the fact that an existing waste treatment device cannot recover metal substances in the using process. A feeding hole is formed in the inner wall of the left side of the crushing box, a driving motor is fixedly installed on the front side of the crushing box, an output shaft of the driving motor extends into the crushing box and is fixedly provided with a Z-shaped rod, the Z-shaped rod is fixedly sleeved with a supporting roller, and the rear end of the Z-shaped rod extends to the rear side of the crushing box; concrete slabs containing steel bars can be ground and smashed, then concrete and the steel bars can be rapidly separated through vibration screening of the screen plate, and therefore the steel bars in the concrete can be conveniently recycled, and good use convenience is achieved.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

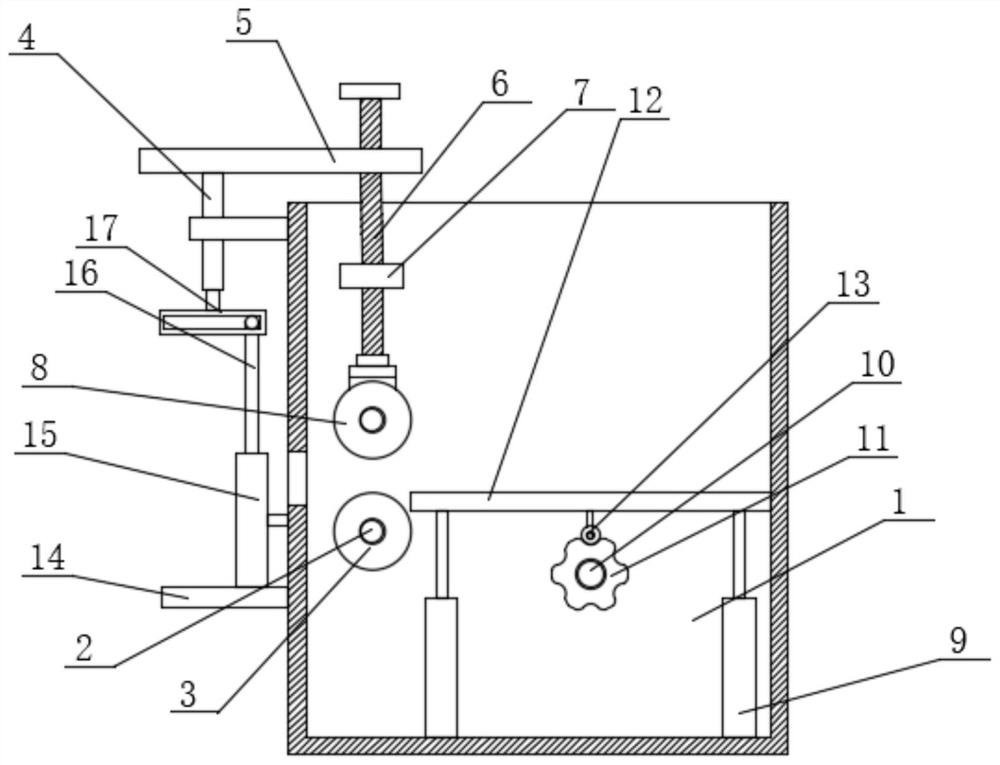

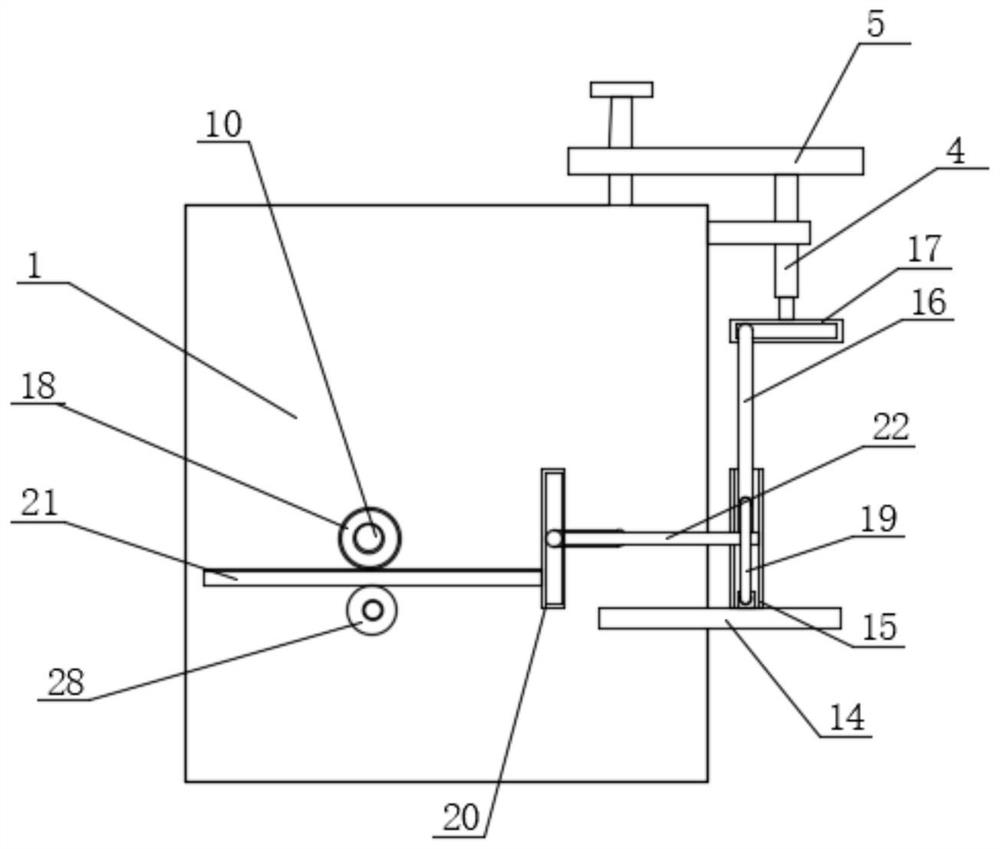

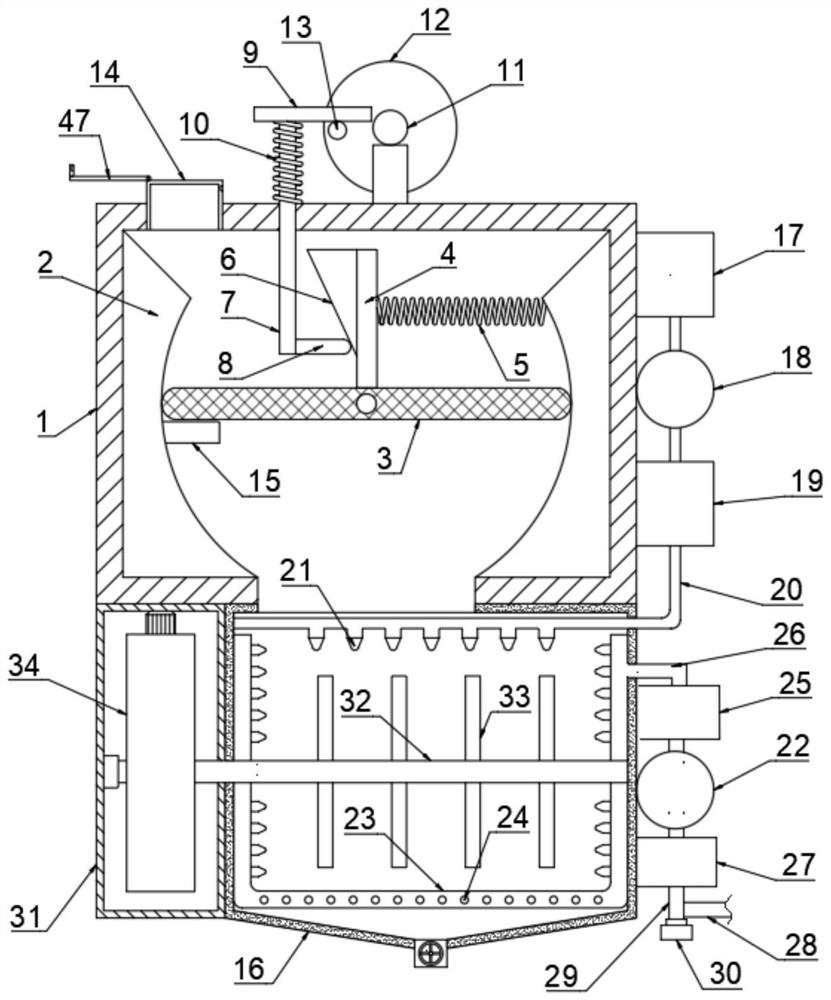

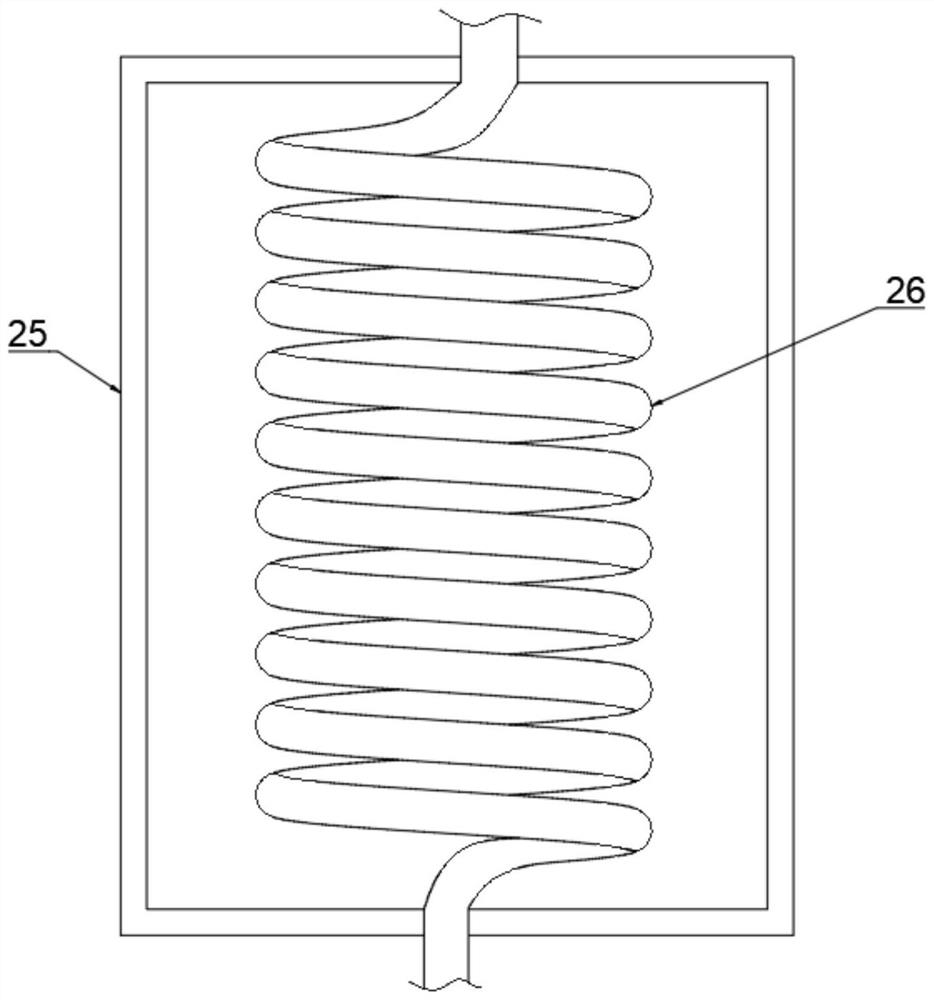

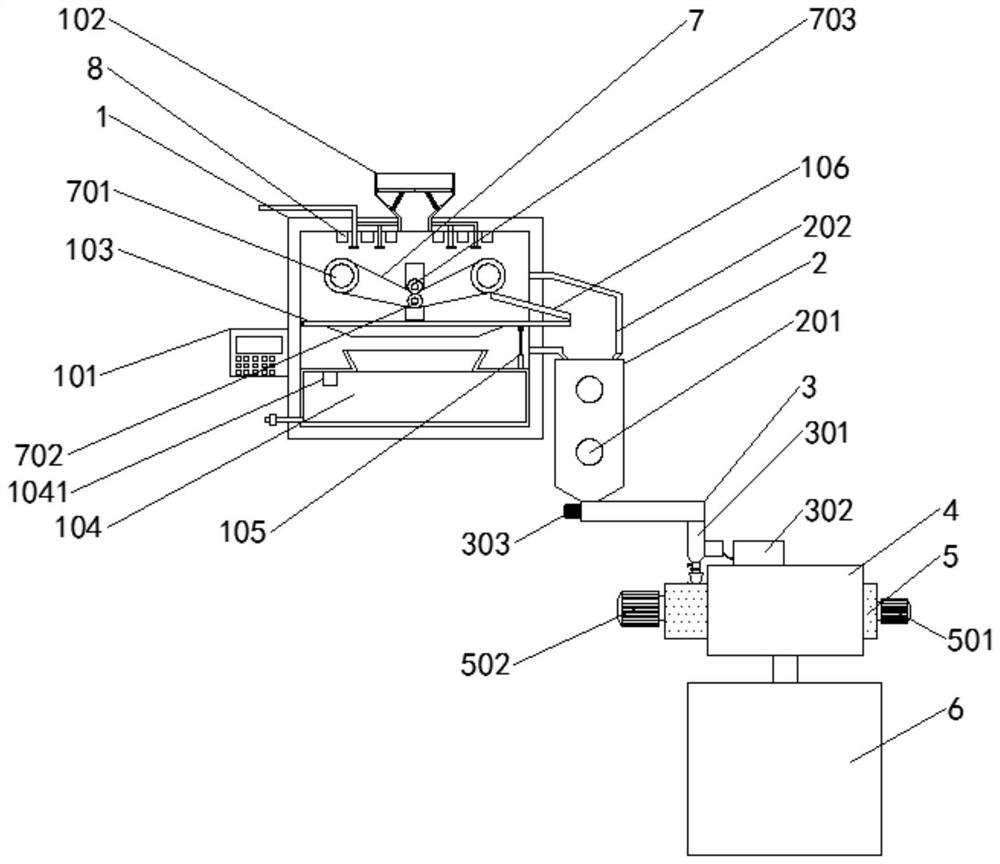

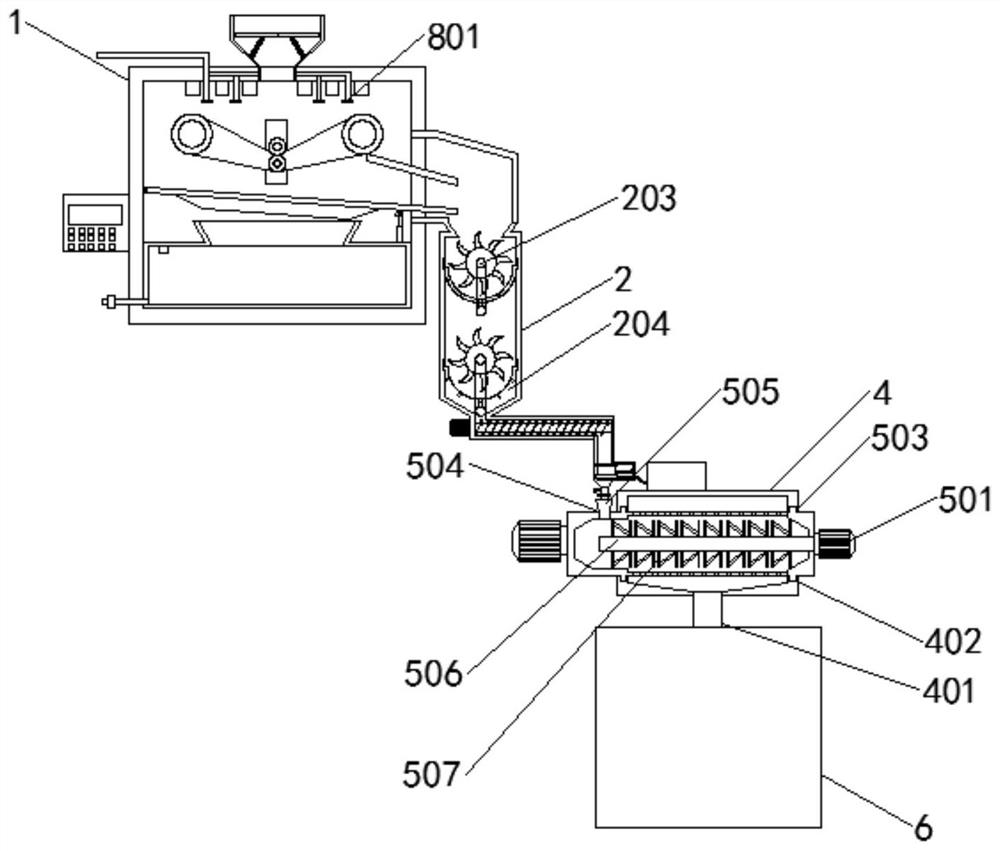

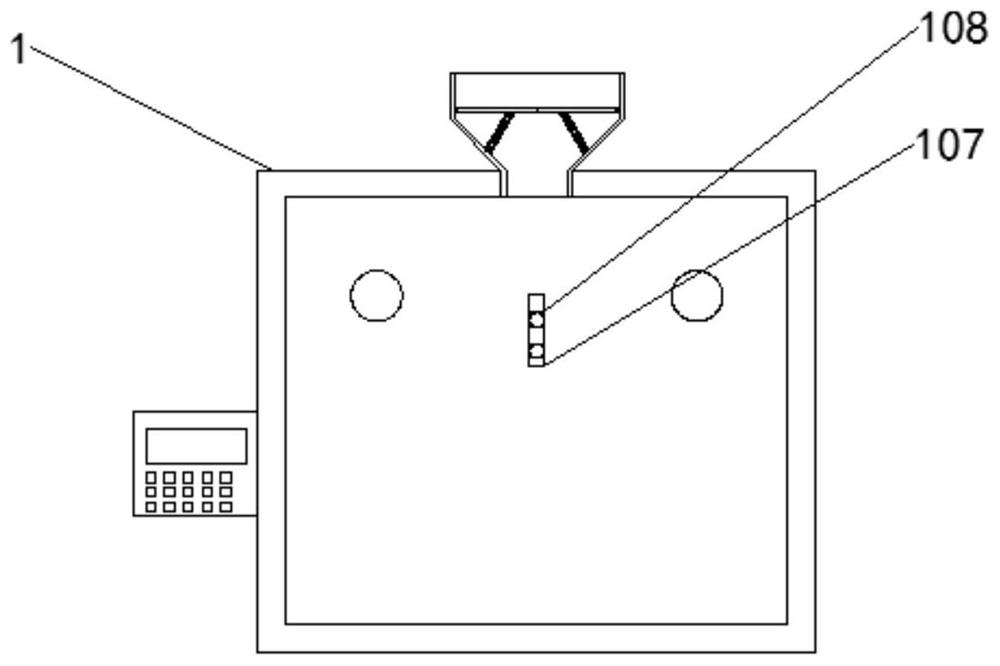

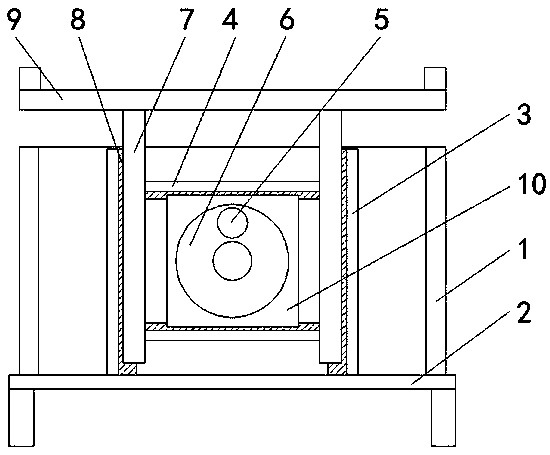

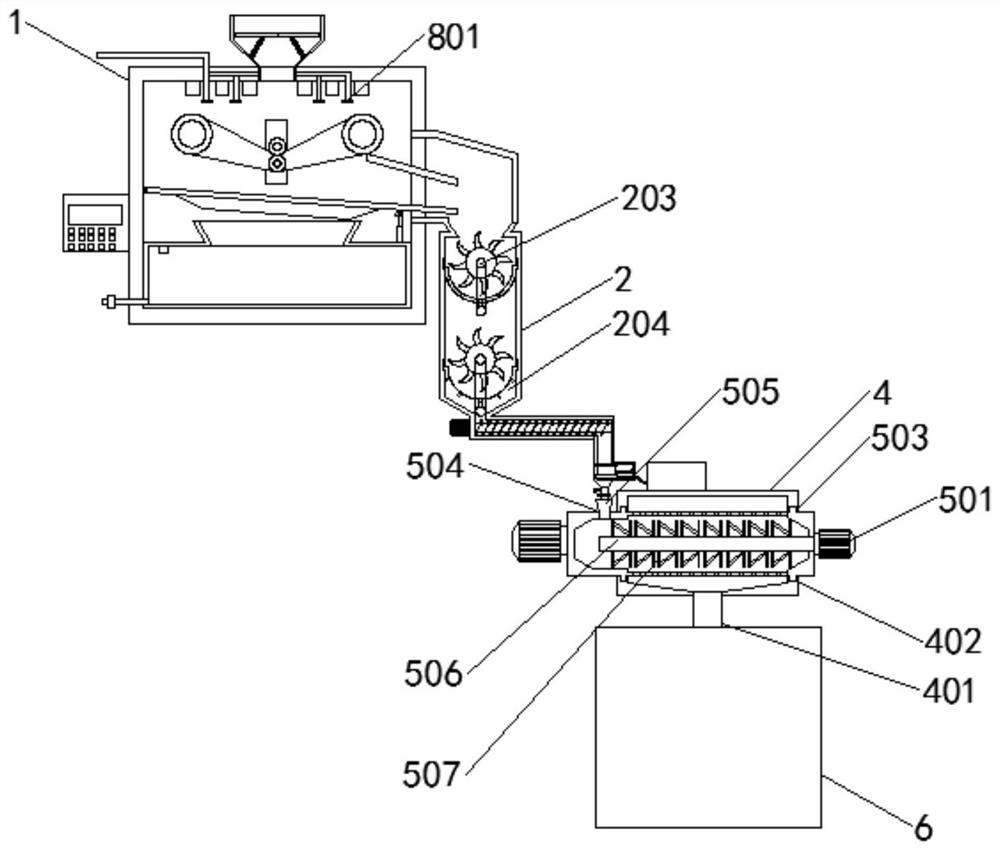

Fluidized drying granulator of pharmaceutical sealed linkage unit

ActiveCN113145012AAchieve vibration effectAvoid cloggingSievingDispersed particle filtrationEngineeringMechanical engineering

The invention relates to a fluidized drying granulator of a pharmaceutical sealed linkage unit, which comprises a filtering chamber, arc-shaped blocks are fixedly connected to the inner walls of the two sides of the filtering chamber, and a first filtering plate making contact with the two arc-shaped blocks is rotationally connected into the filtering chamber; the outer wall of the arc-shaped block located on the left side is fixedly connected with an impact block making contact with the lower side wall of the first filter plate, and the upper side wall of the first filter plate is fixedly connected with a fixing rod. The impact block is intermittently beaten by the filter plate I rotating in a reciprocating manner, so that the effect of vibrating the first filter plate is achieved, powder is prevented from blocking the first filter plate, the smoothness of the first filter plate is ensured, the powder filtering efficiency is ensured, and the pharmaceutical efficiency is improved; the hot air flow is driven by a stirring blade to fully impact and contact the rotating powder, and the powder is suspended and circularly flows in a fluidized state, so that uniform mixing is achieved, the granulation efficiency of the fluidized drying granulator is improved, and waste is reduced.

Owner:福州法莫优科机械科技有限公司

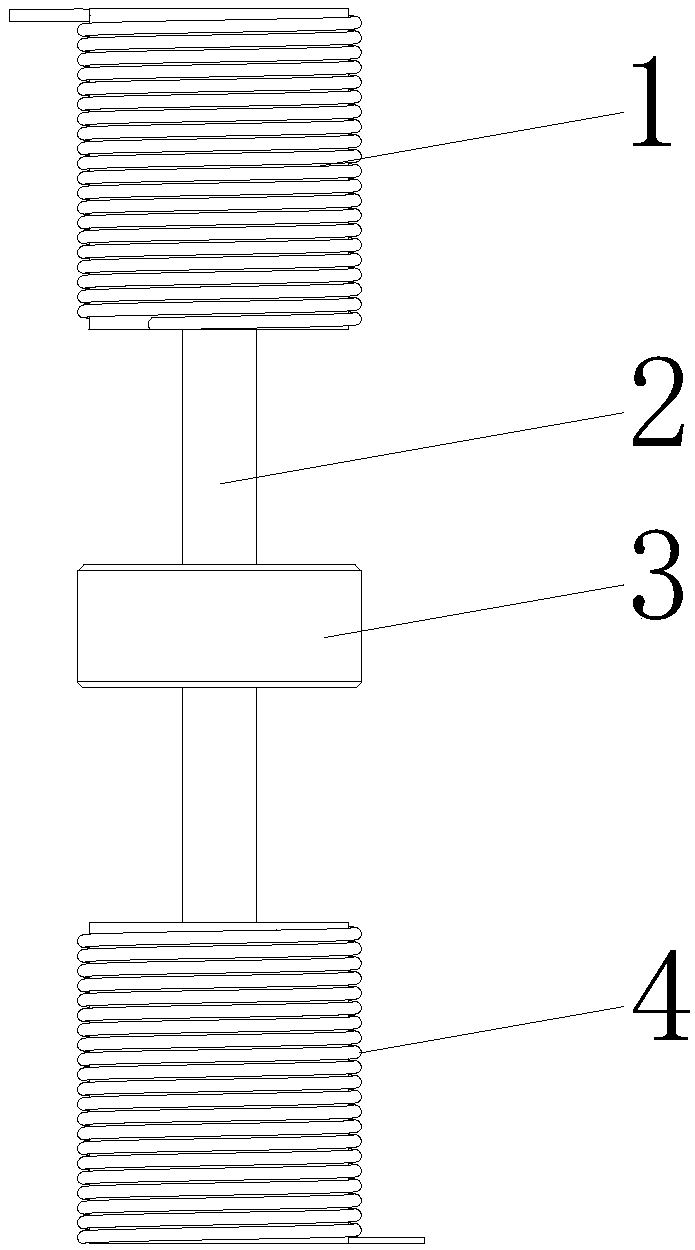

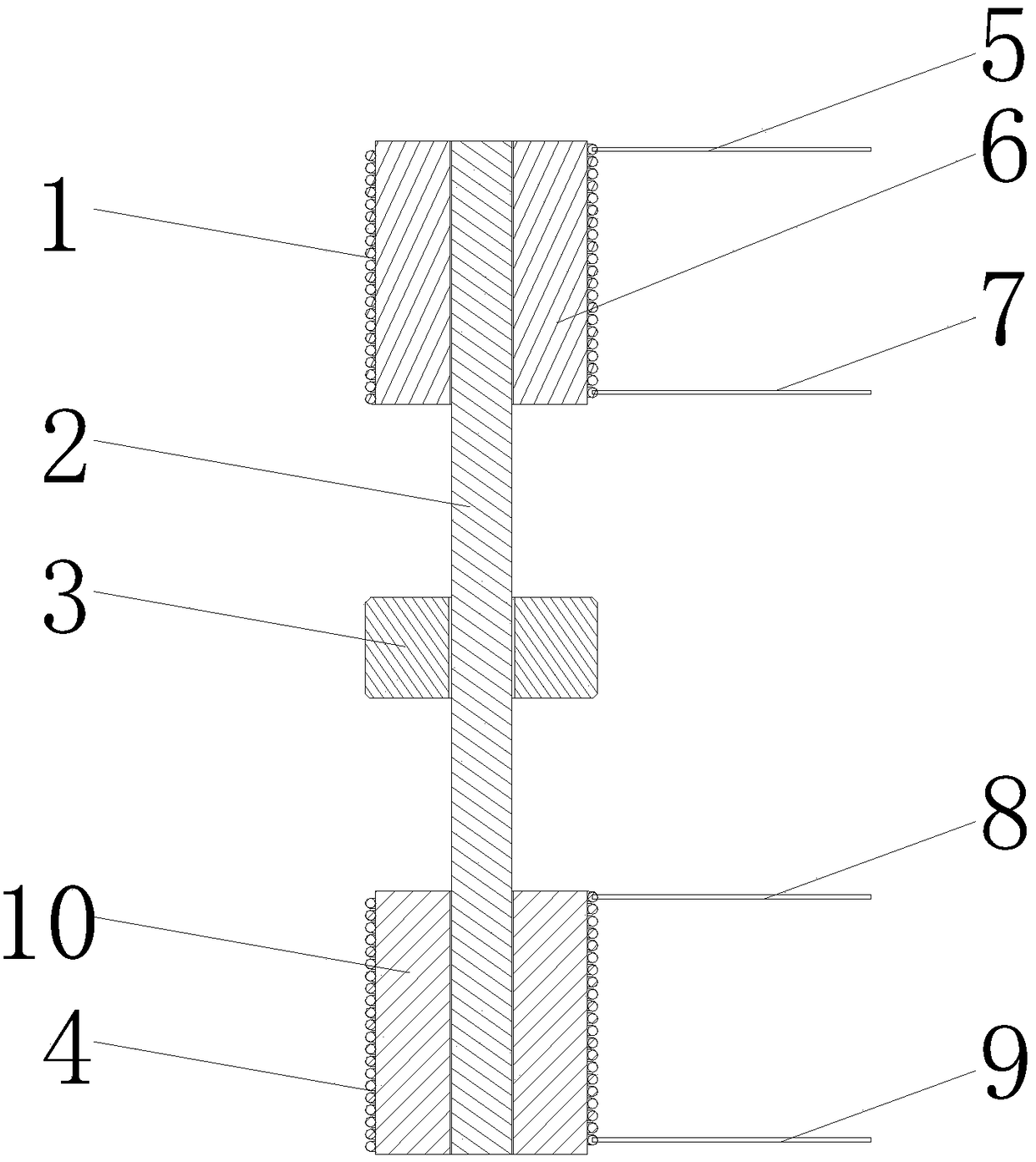

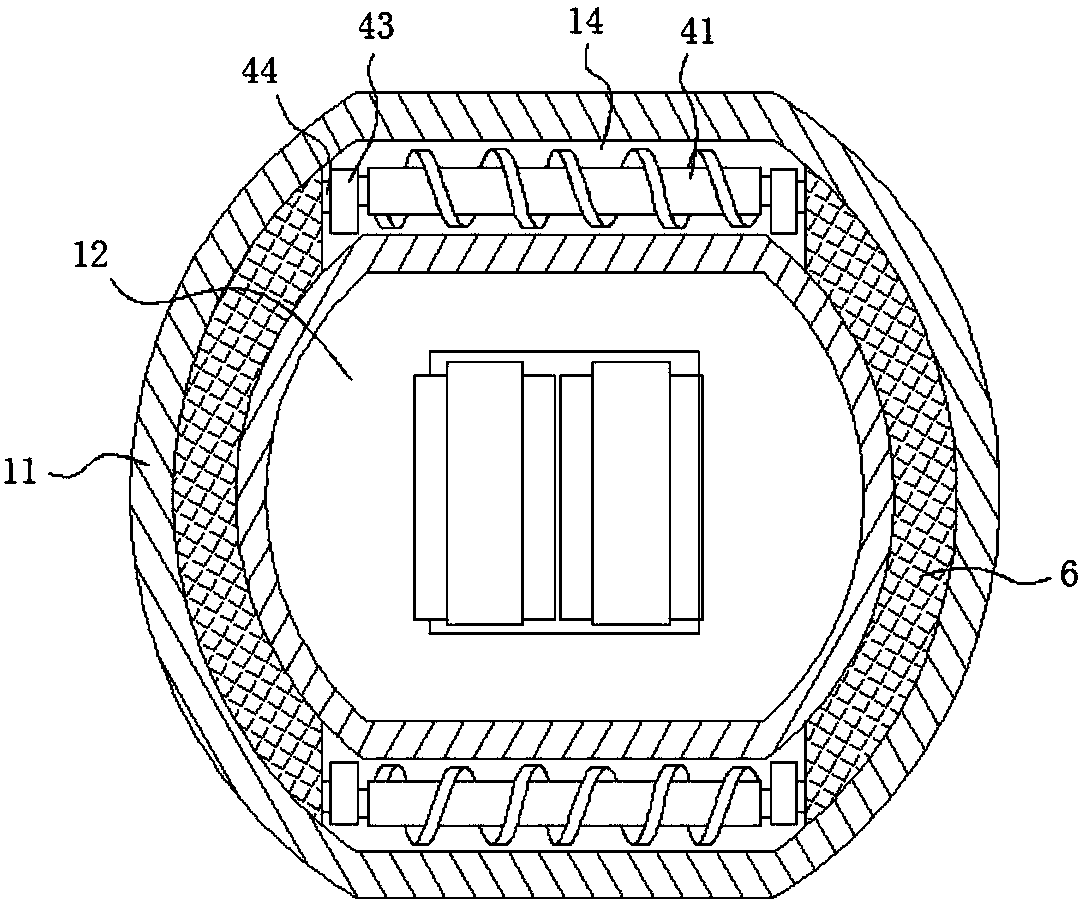

Magnetic attraction vibrator motion device

PendingCN108704826AAvoid functional failureAchieve vibration effectVibration massageMechanical vibrations separationLinear motionPower flow

The invention discloses a magnetic attraction vibrator motion device which comprises a guiding column and a magnet, wherein a first fixing part and a second fixing part correspondingly sleeve the upper and lower ends of the guiding column; a first coil is wound around the outer curved surface of the first fixing part; a second coil is wound around the outer curved surface of the second fixing part; and the magnet sleeves the middle of the guiding column. According to the magnetic attraction vibrator motion device disclosed by the invention, magnetic attraction force which continuously changesup and down can be generated by changing the current directions of the first coil wound around the first fixing part and the second coil wound around the second fixing part; the vibrating effect can be achieved when the magnet on the guiding column is adsorbed by the magnetic attraction force to perform reciprocating motion; the linear motion distance and strength can be changed by changing the current magnitude and the current direction changing frequency; and the permanent magnet regularly moves on the central guiding column, so that both the safety and the reliability can be achieved and the function failure caused by position deviation can be prevented.

Owner:宁海县集美特电器有限公司

Wet ball mill smooth to discharge

The invention relates to the technical field of wet ball mills and discloses a wet ball mill smooth to discharge. The wet ball mill comprises a wet ball mill body. A placing plate is arranged below the outer wall of the wet ball mill body, and the placing plate does not make contact with the outer wall of the wet ball mill body and is in an overhead state. According to the wet ball mill smooth todischarge, the problems that most incoming materials contain soil, unsmooth discharging at the inlet end is caused, and meeting of operation and energy saving requirements is not facilitated are solved; when a leather plug extrusion rod connected to the top of an air cylinder is subjected to downward low pressure from an upper welded hollow disc, the leather plug extrusion rod is pushed to do piston motionin the air cylinder, so that air is input into an air bag, and the air bag is inflated and deflated; and a spring connected to the outer wall of the air bag is in an arc state, after the airbag is inflated, the spring bends outwards, and after the air bag is deflated, the spring bends inwards, so that the vibration effect is achieved, and the materials in a feeding pipe are vibrated.

Owner:安徽国润电力有限公司

Medical waste disposal device

InactiveCN111998348AEasy to controlEasy to operateLavatory sanitoryMedical waste disposalRefuse DisposalsMechanical engineering

The invention discloses a medical waste disposal device. A crushing shaft is arranged in a rotating screen net, the outer sidewall of the crushing shaft is fixedly connected with a plurality of equally distributed crushing knives, a plurality of uniformly distributed screen holes are formed in the middle of the outer sidewall of the rotating screen net in a penetrating manner, and the screen holesare located in a fixed cylinder. The left side of a conveying cavity is fixedly connected with a conveying motor. The top end of the inside of a disposal box is fixedly connected with a plurality ofevenly distributed ultraviolet disinfection lamps, disinfectant spray heads are arranged between every two adjacent ultraviolet disinfection lamps, a filter belt is arranged below the multiple ultraviolet disinfection lamps, the fitter belt is in a V shape, the waste comes in from the disposal box and falls on the filter belt, the filter belt rotates to make the waste be turned over on the filterbelt constantly, the ultraviolet disinfection lamps are turned on, the disinfectant spray heads are opened, the disposal and disinfection of the turnover waste are further facilitated, when the wasteis turned over, the liquid waste flows to the lower side through the filter belt, and thus the effect of separating the liquid waste from solid waste is realized.

Owner:刘贵芳

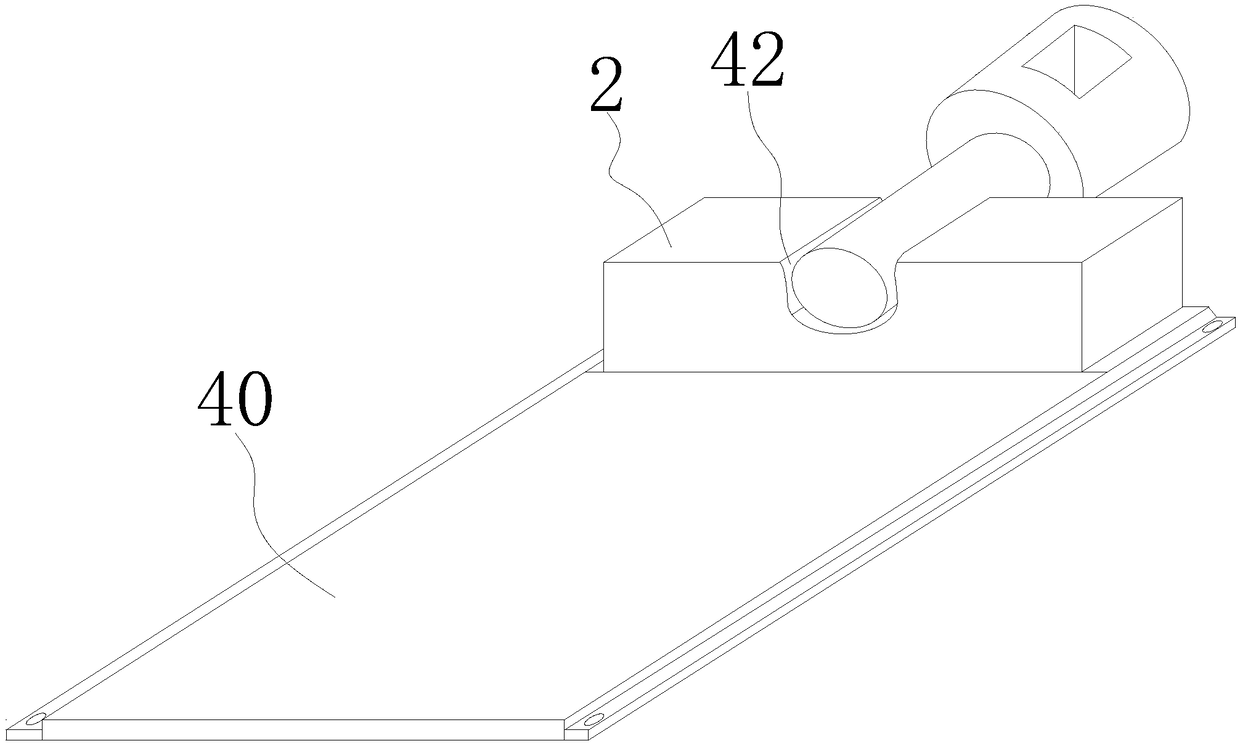

Simple and portable vibrating machine for construction site

InactiveCN108179882ASimple device structureReasonable designRoads maintainenceBuilding material handlingBuilding constructionSupport plane

The invention provides a simple and portable vibrating machine for a construction site, and belongs to the technical field of construction. The simple and portable vibrating machine comprises universal wheels; the top portions of the universal wheels are provided with support plates, and the top portions of the universal wheels are welded at the bottom portions of the support plates; the top portions of the support plates are provided with a support frame and a protective cavity; and the bottom of the support frame is welded to the top portions of the support plates. The simple and portable vibrating machine has the advantages of simple structure, reasonable design and convenient use; the universal wheels are arranged to facilitate movement of the simple and portable vibrating machine andis used for moving the simple and portable vibrating machine during the vibration process, the movement and the vibration of concrete are performed at the same time, thereby greatly improving the working efficiency; a drive device is arranged to facilitate the downward movement of a vibrating plate, thereby vibrating the concrete and improving the production quality of the concrete; and a resetting device is arranged to facilitate the resetting of the vibrating plate, and under the action of the drive device, the vibrating plate is moved up and down to achieve the vibration effect and improvethe production quality of the construction.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

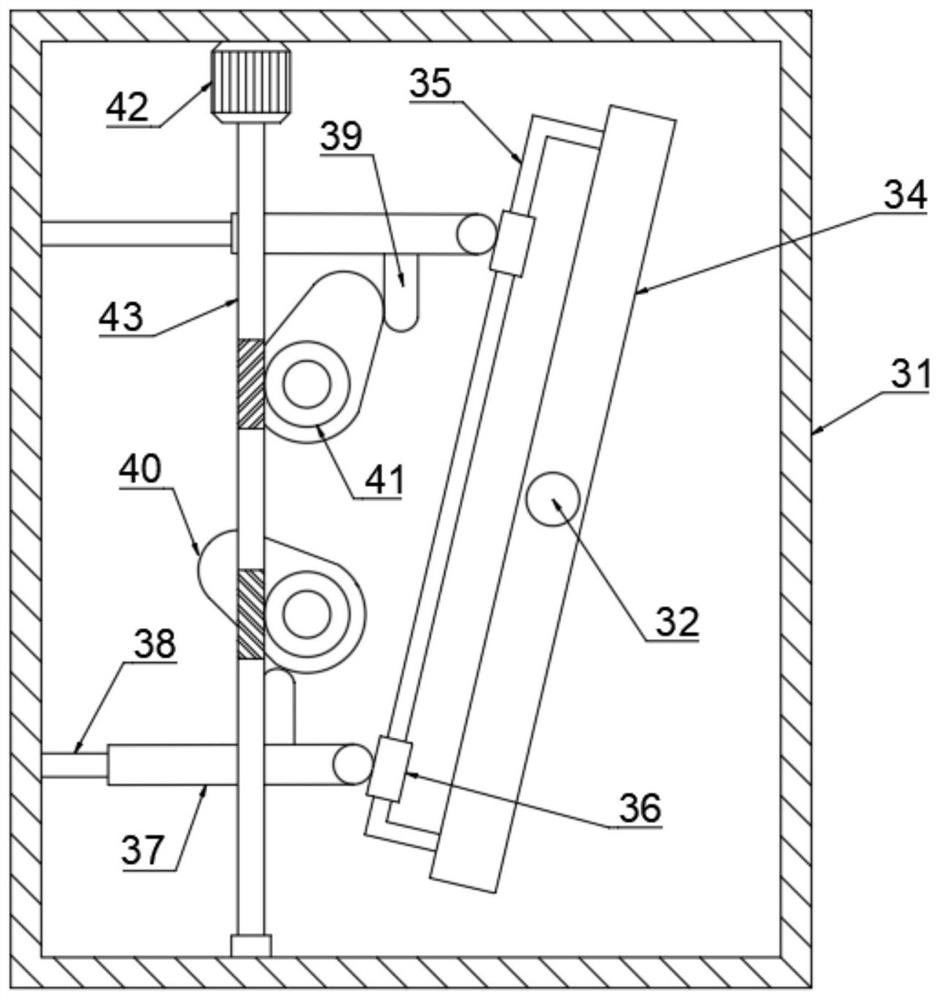

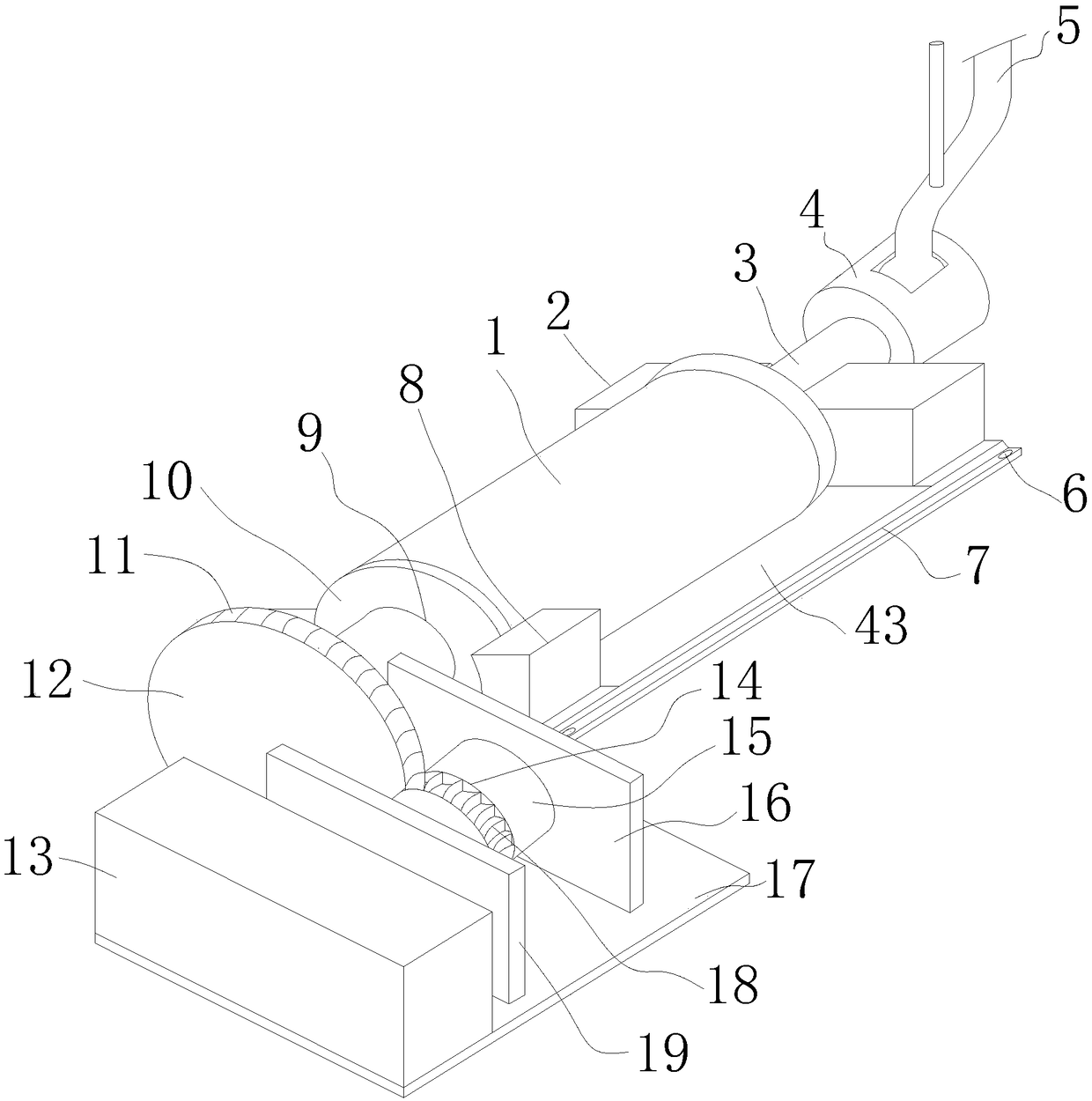

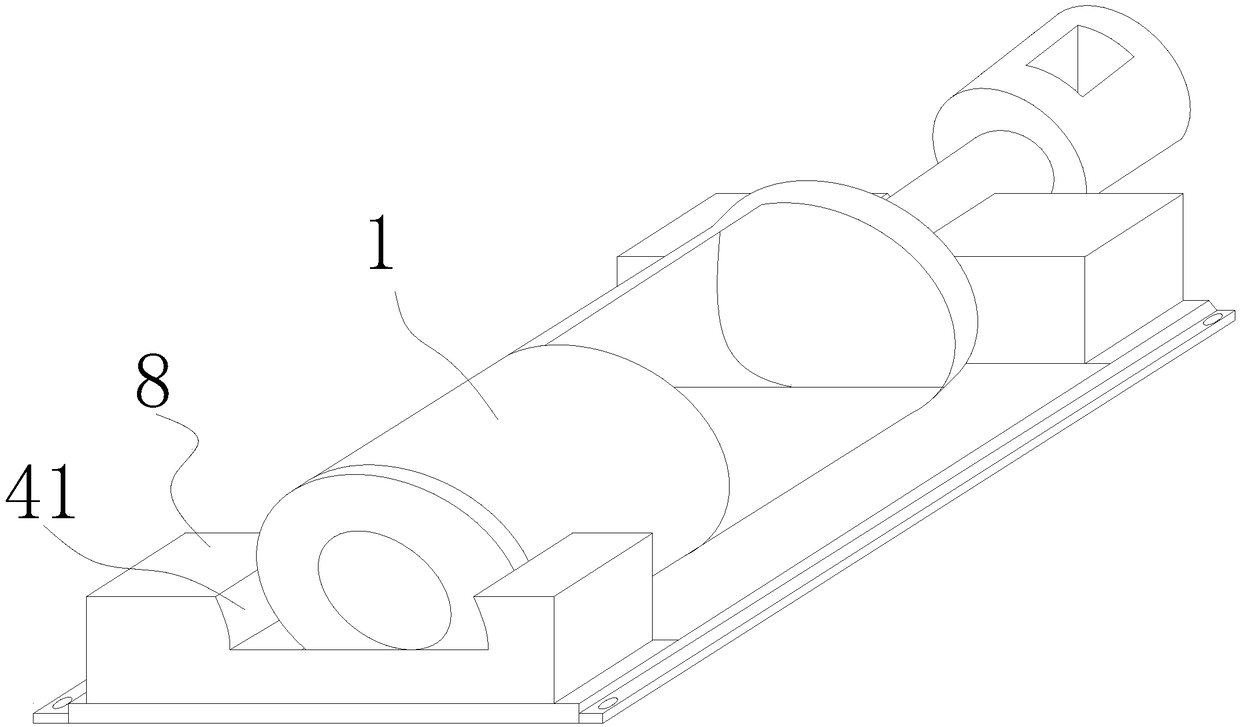

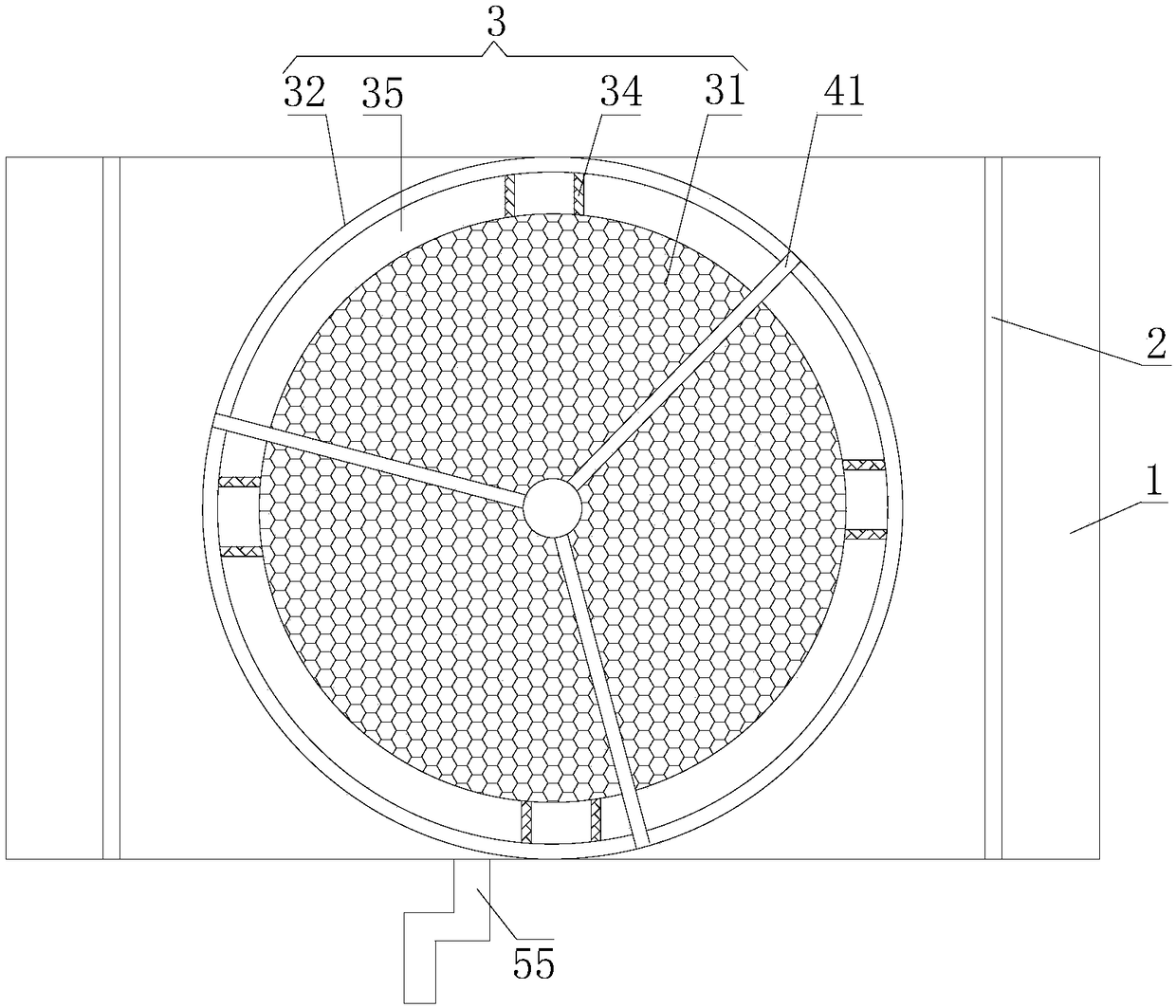

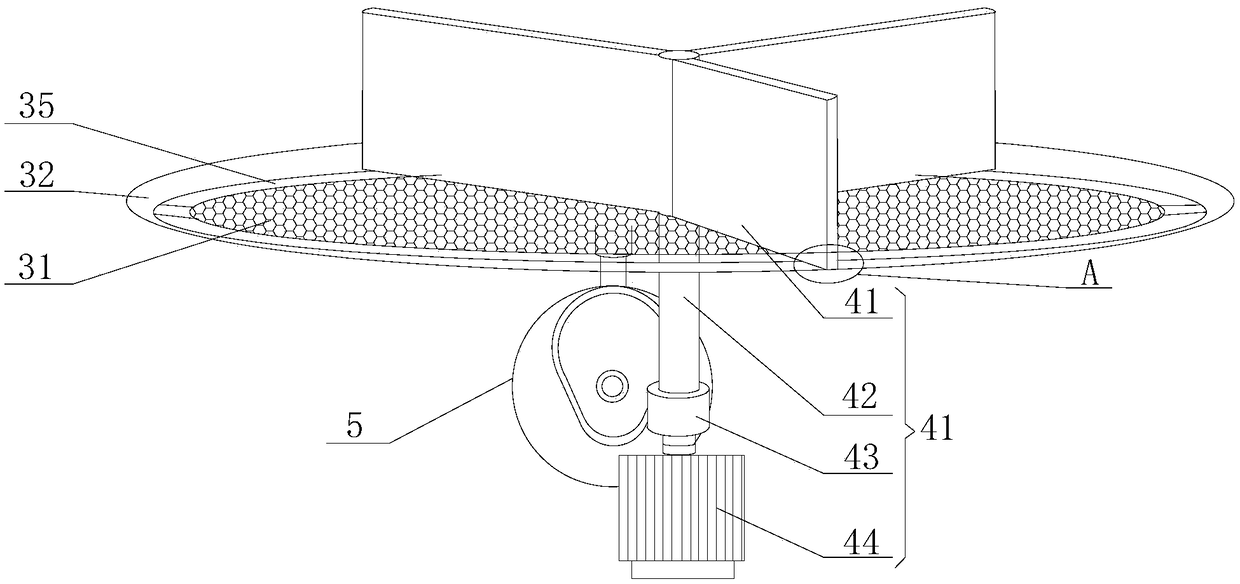

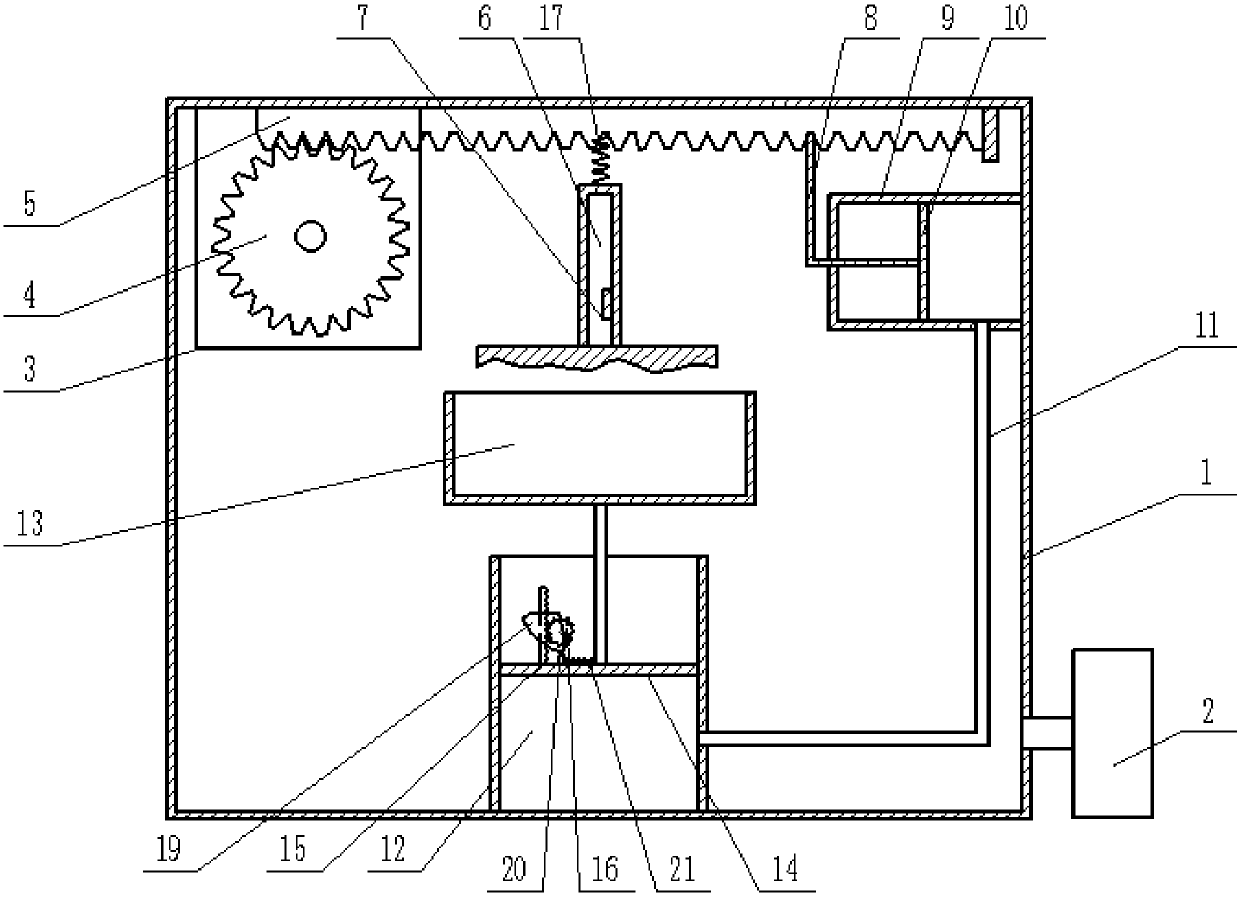

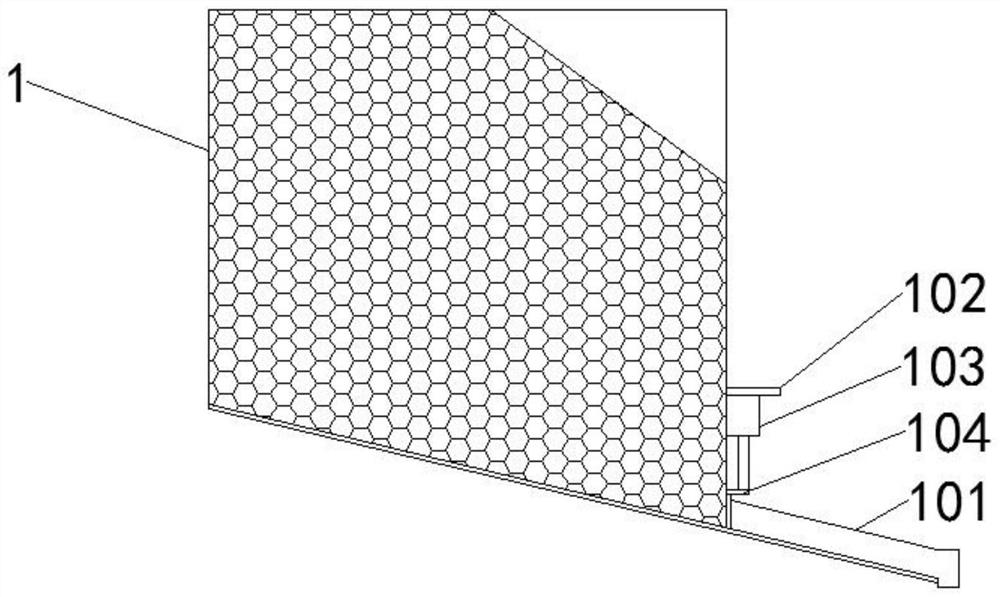

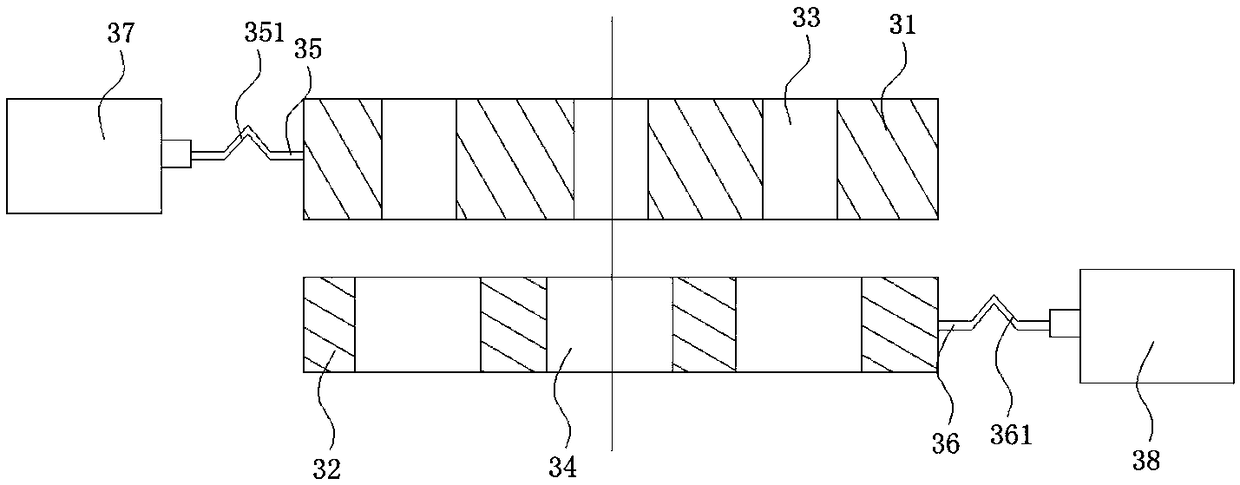

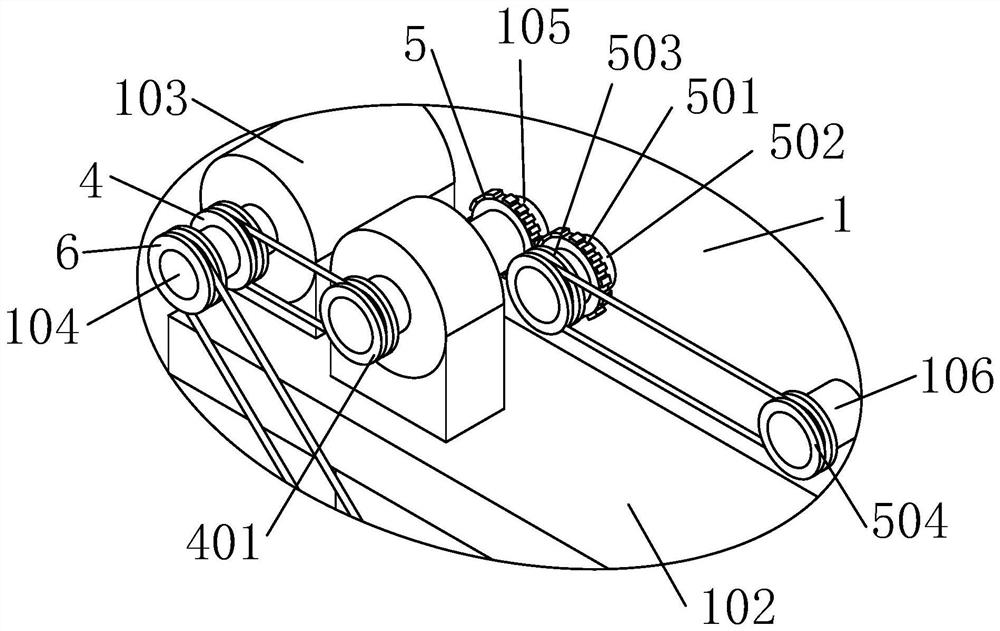

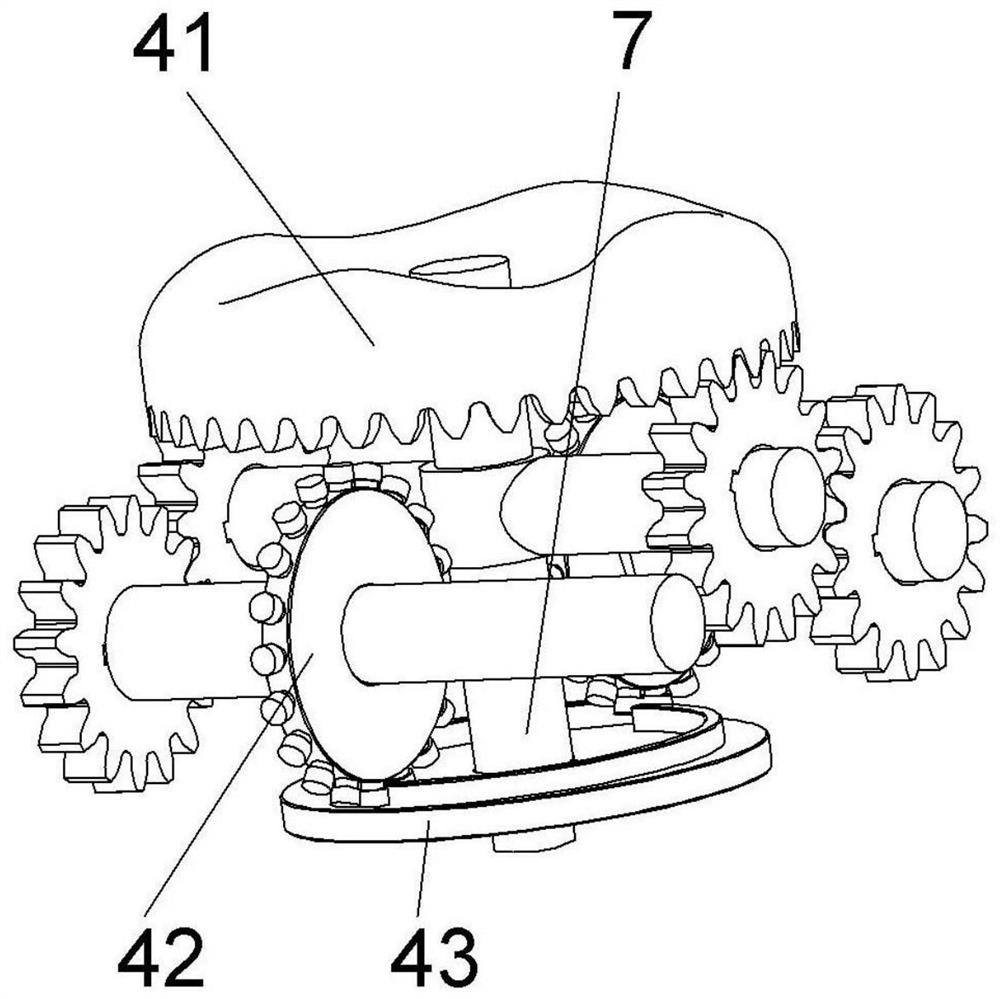

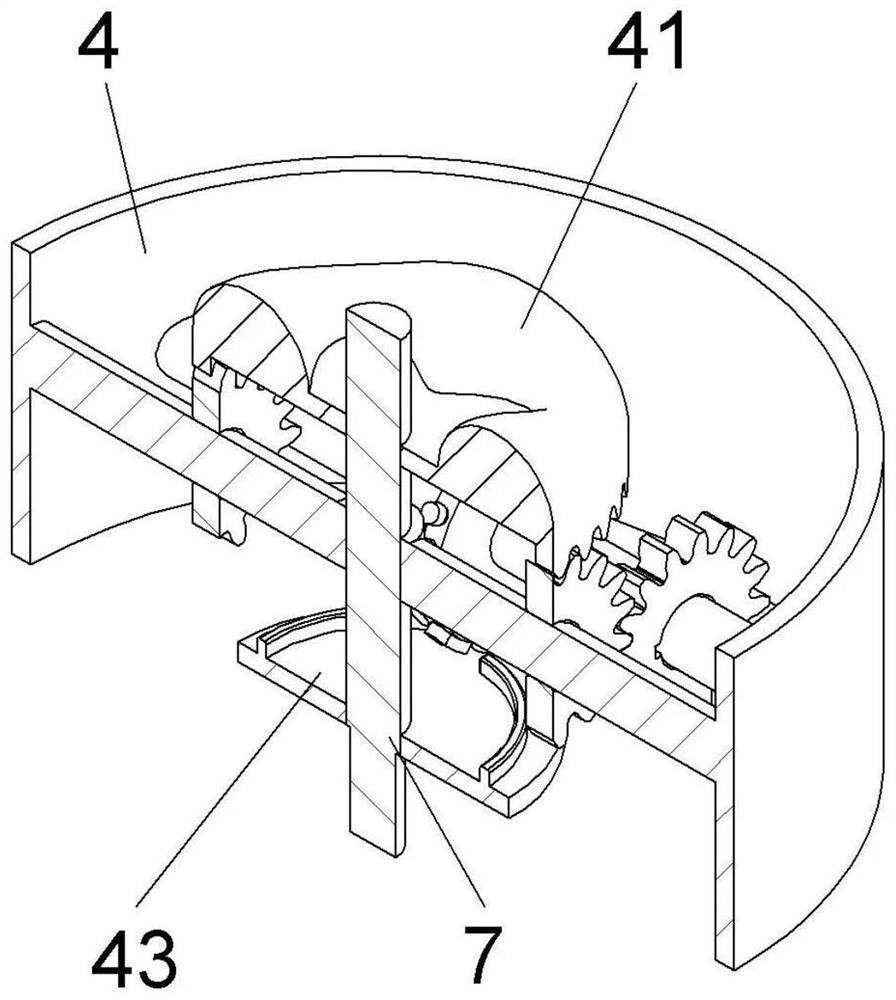

Material sieving device and operation method thereof

InactiveCN109078840ASimple transmissionAchieve vibration effectSievingScreeningCircular discCoupling

The invention discloses a material sieving device and an operation method thereof. The material sieving device comprises a rack. A protecting cover is mounted on the rack, and a material sieving mechanism and a material separating mechanism are mounted in the protecting cover. The material sieving mechanism comprises a material sieving net and a material sieving steel ring, and the material sieving net is connected to the material sieving steel ring through a stretching spring. A vibration mechanism is arranged below the material sieving net and comprises a transmission rod, a cam and a disc.The material separating mechanism comprises a three-blade material separating plate, a rotating shaft, a coupling and a motor. The motor is arranged on the lower portion of a material collecting box,and the interior of the material collecting box is divided into a finished material bin and a waste material bin which correspond to the material sieving net and a material filtering trough. Accordingto the material sieving device and the operation method thereof, building materials on the material sieving net are sieved and filtered through the material sieving mechanism and the vibration mechanism, the material sieving device is good in vibration effect, and the mechanism transmission mode is simple; and secondly, the situation that the large-particle materials remain on the material sieving net, and consequently, the sieving efficiency of the subsequent process is affected can be avoided through the material separating mechanism, the whole device treats the materials in a graded mode,the collecting effect is better, reutilization in the subsequent process is facilitated, and energy conservation and environmental protection are achieved.

Owner:ANHUI NVISION TECH DEV

Rice threshing device with drying function

InactiveCN108271536AReduce damageEasy to separateThreshersSeed preservation by dryingGrain storageEngineering

The invention discloses a rice threshing device with a drying function. The rice threshing device comprises a fixed plate, two supporting plates are fixedly connected to the upper portion of the fixedplate, a threshing box is rotatably connected to the supporting plates through a first bearing, a first motor is arranged at the right side of the threshing box, an output shaft of the first motor ishorizontal, and a first rotary shaft is fixedly connected to the output shaft of the first motor, penetrates through the threshing box and is provided with threshing blades; a second motor is fixedlyconnected to the left side of the threshing box through a second rotary shaft, and is fixedly connected with the left part of the fixed plate through a supporting pillar; a grain storage box is further arranged at the upper portion of the fixed plate, and a drying box is arranged inside the grain storage box and is internally provided with a heat exchange device. The rice threshing device has theadvantages that the structure design is reasonable, rice straw and rice can be completely separated, and the rice can be dried; the rice threshing device is suitable for threshing the rice.

Owner:杨露萍

Special-shaped glass powder feeding device

ActiveCN108031622AAvoid the problem of accumulation on the concave surface of special-shaped glassPowder evenlyLiquid surface applicatorsCoatingsReciprocating motionEngineering

The invention relates to the technical field of surface coating devices, and particularly discloses a special-shaped glass powder feeding device. The device comprises a box body, a vacuum pump, a power mechanism, a working mechanism and a transmission mechanism; the power mechanism comprises a motor, a first gear and a first rack meshed with the first gear, and the middle section of the first rackis provided with a paw for fixing special-shaped glass; the transmission mechanism comprises an L-shaped handle arranged on the first rack and a cylinder body, wherein a first piston is arranged inside the cylinder body in a sliding fit mode, and the free end of the handle is fixedly connected with the first piston; the working mechanism comprises a groove body communicating with the cylinder body and a bearing groove arranged above the groove body, the size of the bearing groove is larger than the size of the special-shaped glass, and the groove body is arranged at the bottom of the box body; and a second piston is arranged in the groove body in a sliding fit mode, and the second piston is fixedly connected with a crank sliding block mechanism for driving horizontal reciprocating motionof the bearing placing groove. According to the technical scheme, the surface of the special-shaped glass can be uniformly coated with powder, and therefore, the device can be widely applied to the powder feeding of the special-shaped glass.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

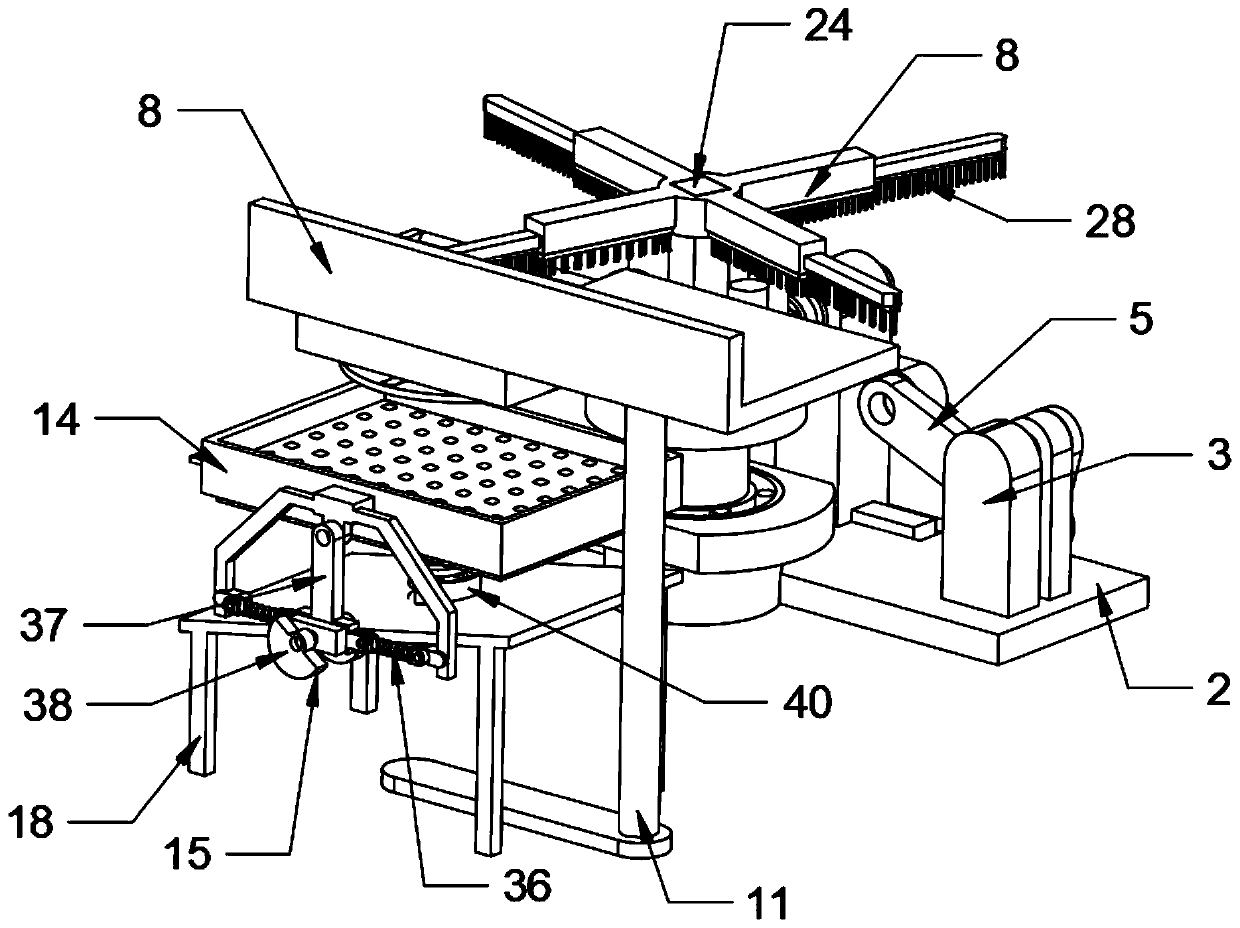

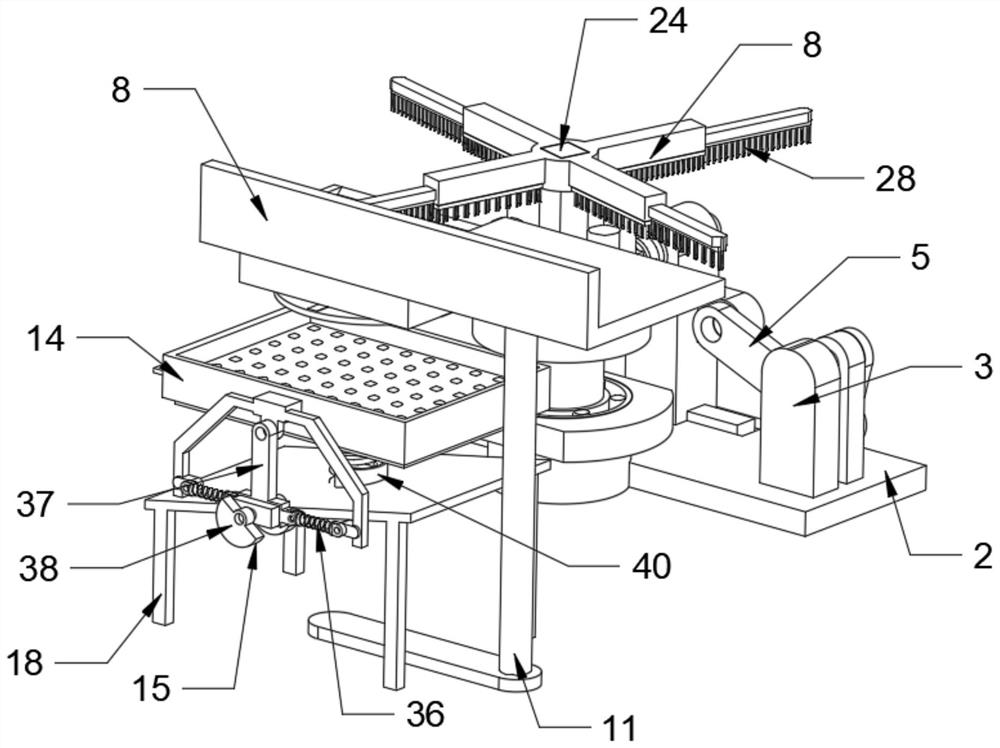

Automatic screening device for building gravel

The invention discloses an automatic screening device for building gravel. The automatic screening device comprises a screening disc and a rack. A first motor is mounted above the rack, and the outputend of the first motor is fixedly connected with a first transmission rod. The end, away from the first motor, of the first transmission rod is rotationally connected with a second transmission rod,and the end, away from the first transmission rod, of the second transmission od is rotationally connected with a sliding block. The sliding block is in sliding connection with the rack, and an intermittent mechanism is slidably connected in the sliding block. The upper portion of the intermittent mechanism is fixedly connected with a rotary frame, and the surface of the rotary frame is fixedly connected with a material brushing device. A baffle is arranged below the material brushing device, and the lower portion of a baffle is fixedly connected with a fixed column. The fixed column is fixedly connected with the ground, and a material falling hole is formed in the upper surface of the baffle. A conveying device is mounted in the material falling hole, a screening frame is arranged below the conveying device, and the surface of the screening frame is clamped with the screening disc. The automatic screening device has adaptability and is high in automation degree, the material screeningefficiency can be improved, the structure is simple, and high practicality is achieved.

Owner:湖南砼创物联科技有限公司

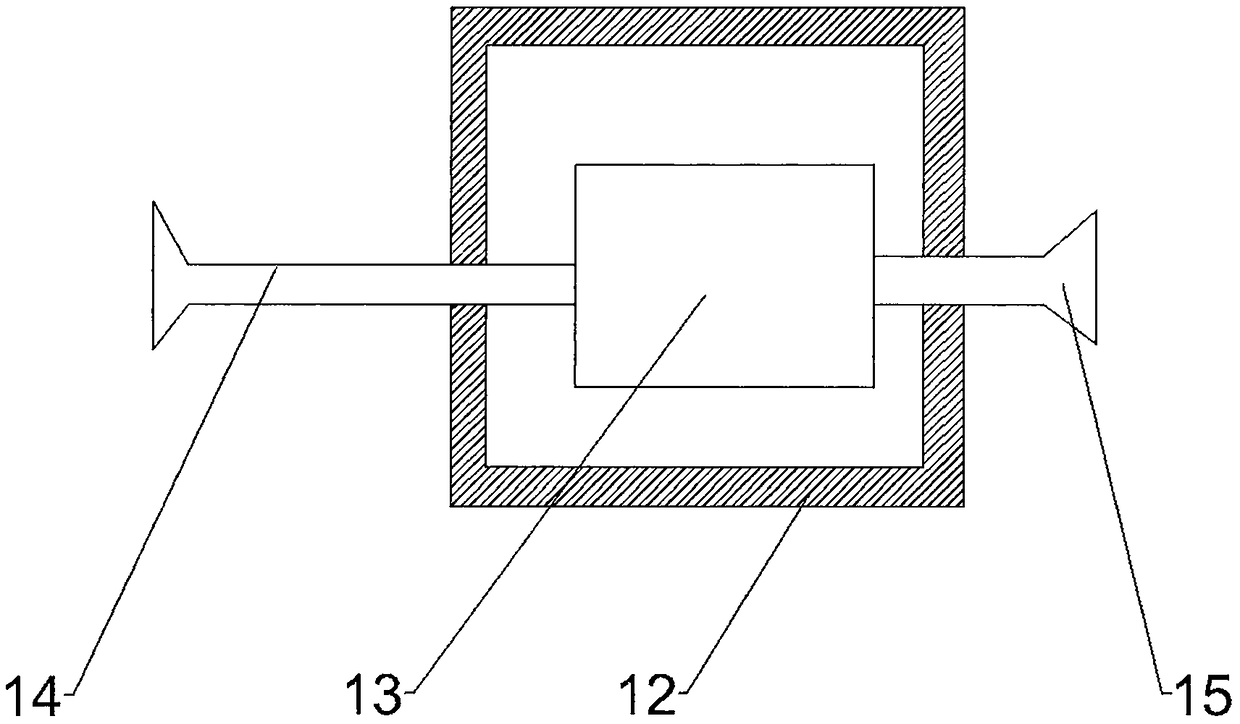

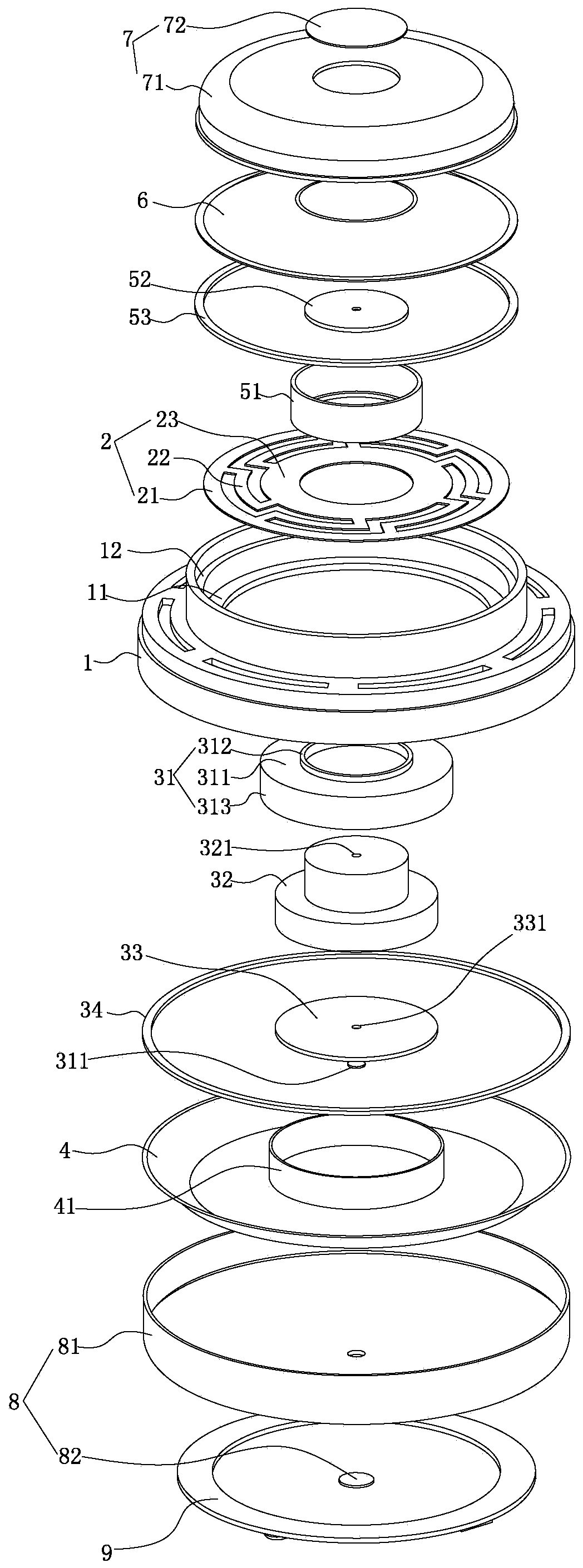

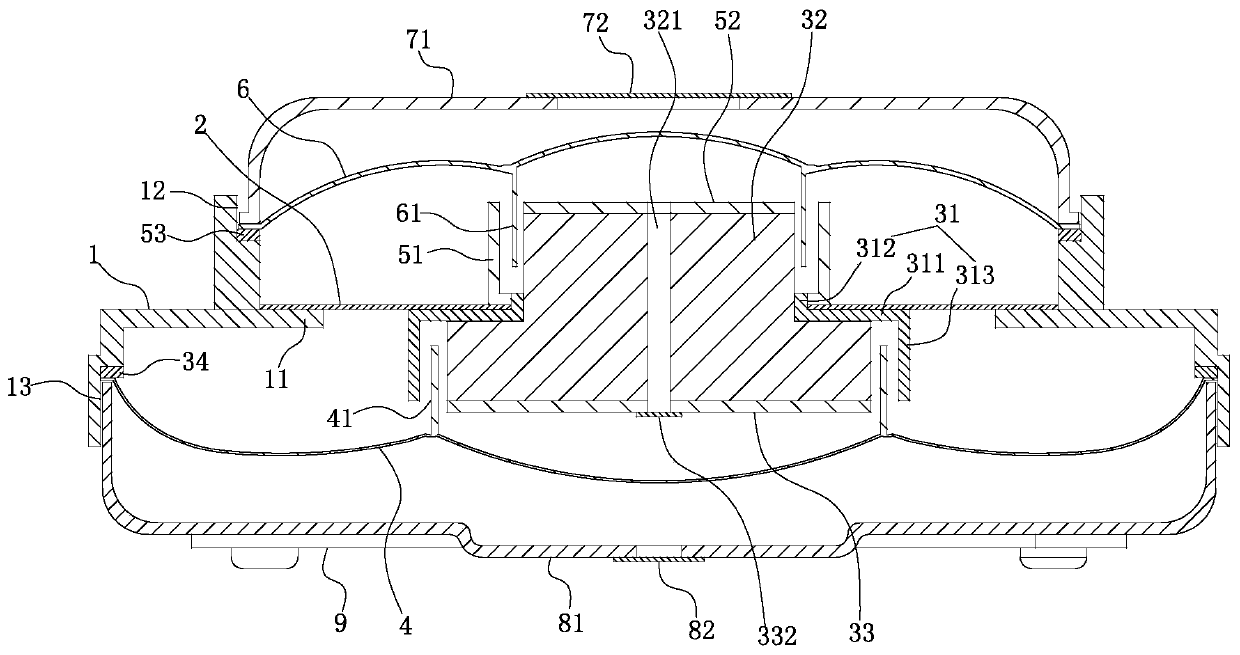

Double-diaphragm vibration horn system

ActiveCN111464926AMeet the use requirementsWith vibration effectEarpiece/earphone attachmentsDiaphragm constructionStructural engineeringWasher

The invention discloses a double-diaphragm vibration horn system. The double-diaphragm vibration horn system comprises a shell; a metal elastic sheet which comprises an outer ring body, an elastic body and an inner ring body which are fixed in the shell and are integrally connected; a large magnetic circuit assembly which comprises a large basin stand fixed in the inner ring body, a magnet, a large washer and a large copper ring, wherein the magnet, the large washer and the large copper ring are fixedly arranged in the large basin stand in a penetrating manner; a large voice diaphragm which isinstalled at the lower end of the large copper ring, wherein a large voice coil at the upper end of the large voice diaphragm extends into a gap between the large basin stand and the magnet; a smallmagnetic circuit assembly which comprises a small basin stand fixed at the upper end of the large basin stand, a magnet fixedly arranged in the small basin stand in a penetrating manner, a small washer and a small copper ring; a small voice diaphragm which is mounted at the upper end of the small copper ring, wherein a small voice coil at the lower end of the small voice diaphragm extends into a gap between the small cone frame and the magnet; a small protective cover assembly which is fixed at the upper end of the shell; and a large protective cover assembly which is fixed at the lower end ofthe shell. The large basin stand, the small basin stand, the magnet, the large washer, the small washer and the inner ring body are fixed together and can vibrate up and down along with up-down vibration of the large voice diaphragm and the small voice diaphragm.

Owner:DONGGUAN LIESHENG ELECTRONICS CO LTD

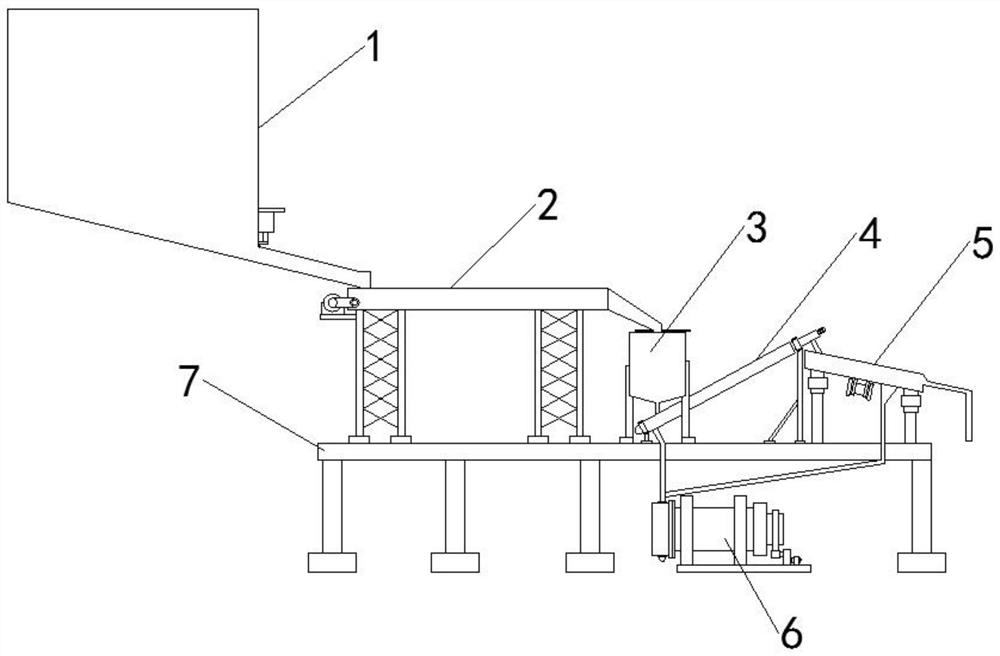

Combined type feeding device used in gravel production

InactiveCN113019547AEasy to transportEasy for preliminary screeningSievingScreeningElectric machineryVibration motor

The invention discloses a combined type feeding device used in gravel production, and belongs to the technical field of gravel production feeding equipment. According to the technical scheme, the combined type feeding device is characterized by comprising a supporting base, wherein a hopper is arranged above the left side of the supporting base, a feeding frame, a crushing cavity, a feeding barrel and a vibrating screen are sequentially arranged above the supporting base from left to right, a gravel washing machine is arranged below a supporting base, the crushing cavity is used for crushing processing, crushed gravel is completely separated from silt solidified on the gravel, a feeding motor is started, a spiral shaft rotates, the feeding barrel conveniently conveys the crushed gravel to the position above the vibrating screen to be screened, screening holes penetrate through the outer side wall of the feeding barrel, when the gravel is rotationally conveyed in the feeding barrel, the silt is screened out of the feeding barrel, preliminary screening of the gravel is facilitated, a vibration motor is started, screening operation of the gravel is facilitated, the purpose that the gravel and the silt are completely screened is achieved, and therefore, the production and processing quality of the gravel is improved.

Owner:甘肃建投矿业有限公司

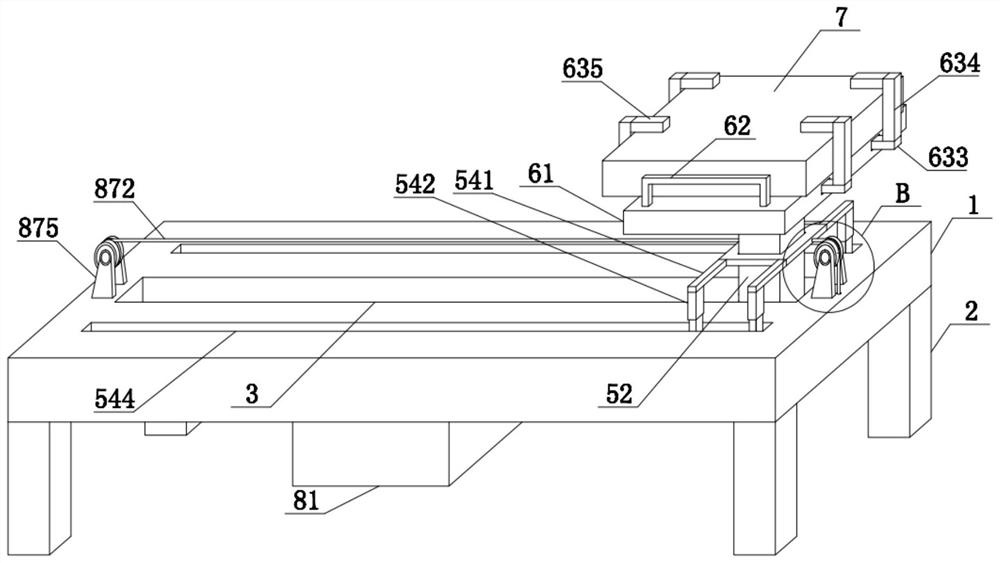

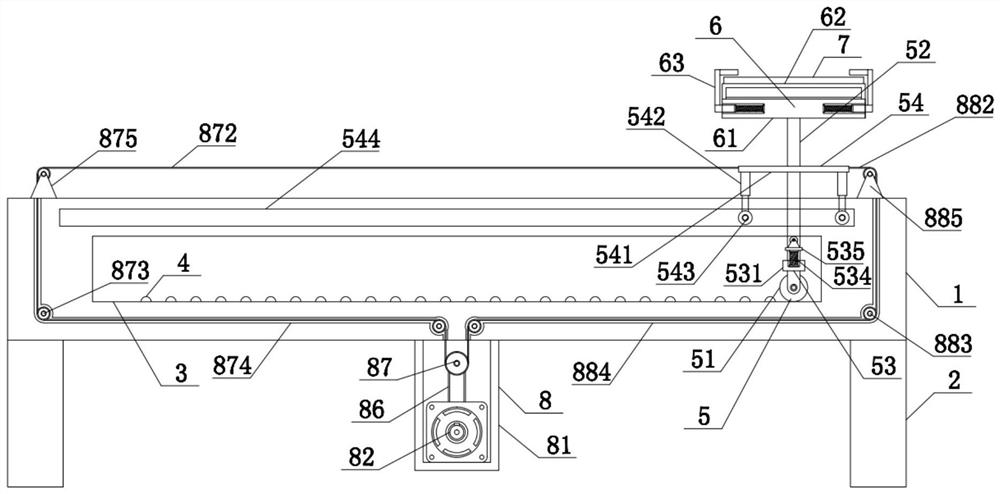

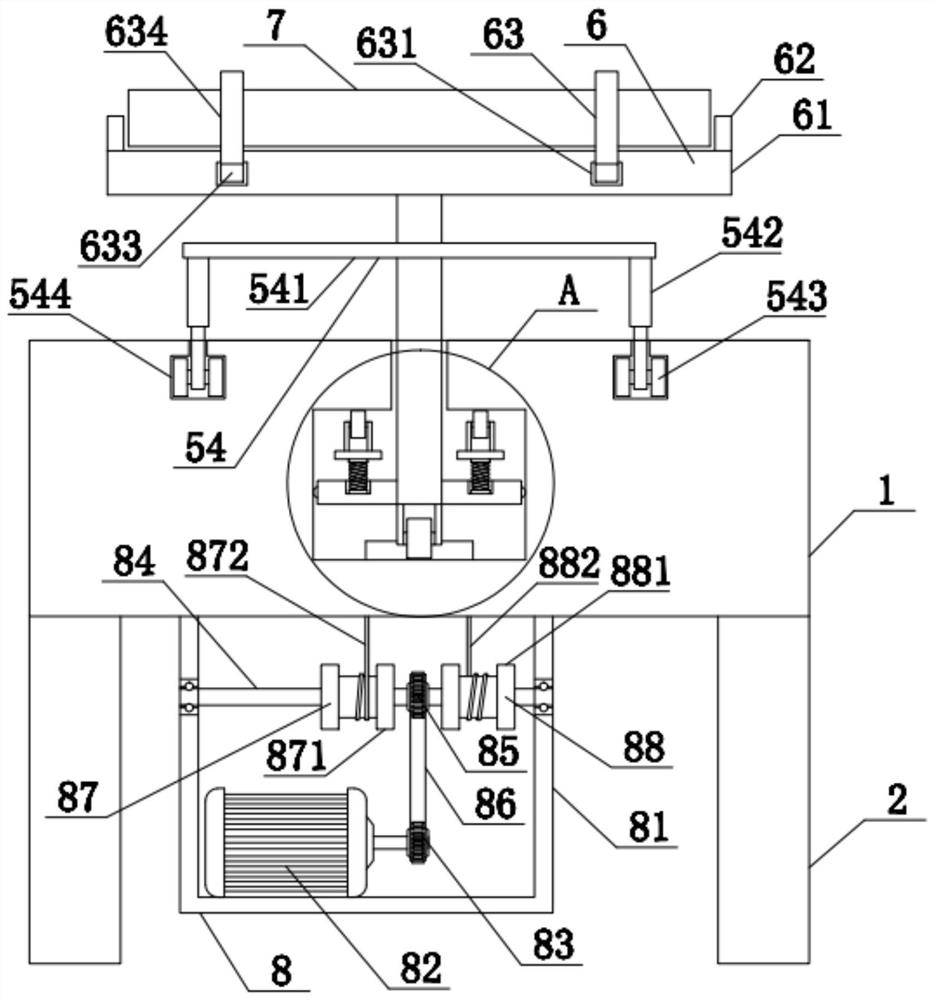

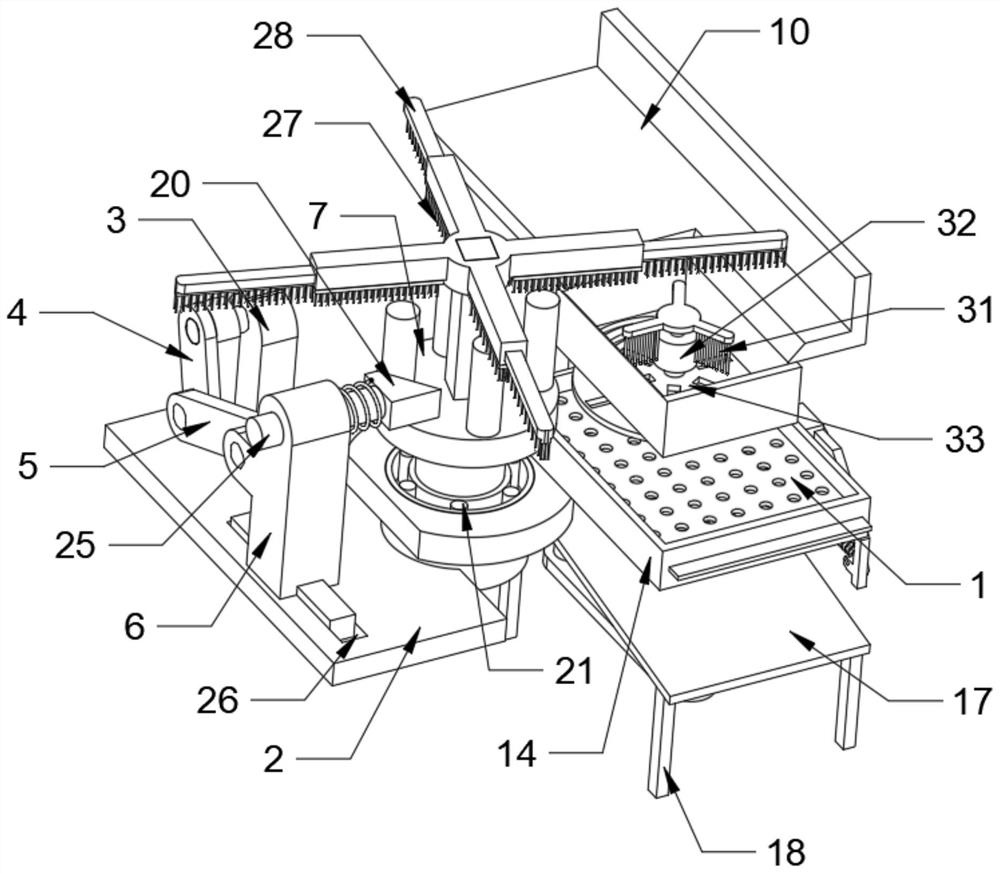

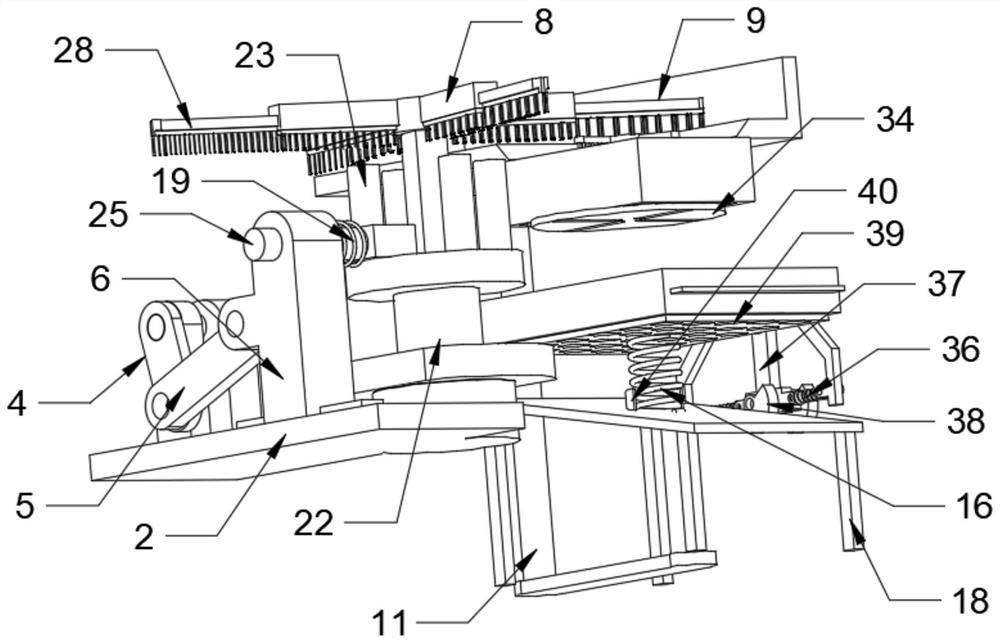

Automatic vibrating equipment for concrete in building angle plate combined mold

ActiveCN112428388AConvenient vibrating workAchieve vibration effectCeramic shaping apparatusArchitectural engineeringStructural engineering

The invention discloses automatic vibrating equipment for concrete in a building angle plate combined mold. The automatic vibrating equipment comprises a vibrating table, supporting legs are fixedly connected to chamfers at the lower end of the vibrating table, a first cavity is formed in the vibrating table, a vibrating protruding block is fixedly mounted in the first cavity, and a vibration mechanism is movably connected into the first cavity. The fixing mechanism can place and fix a combined die body, a transmission mechanism drives the vibration mechanism to move, and a first roller makescontact with the vibrating protruding block in the moving process; the first roller moves up and down by arranging the vibrating protruding block; the first roller rebounds rapidly through a limitingassembly, so that the vibration effect is achieved; and vibration is transmitted to the fixing mechanism through stand columns, so that the combined mold body movably connected into the fixing mechanism vibrates, and the vibration work of concrete in the mold is facilitated. The vibration work of the mold is facilitated, and rapid and batch production can be achieved.

Owner:江西华安建设集团有限公司

Equipment for building construction

InactiveCN108405123AShake out wellImprove filtering effectGrain treatmentsFault rateWaste management

The invention discloses equipment for building construction. The equipment comprises a primary processing chamber and a secondary processing chamber which communicates with the primary processing chamber; the primary processing chamber comprises a shell and an inner processing chamber arranged in the shell; the communication part of the primary processing chamber and the secondary processing chamber is provided with a filter component used for sieving a material; the primary processing chamber is internally provided with a recover device used for moving the material, accumulating on the filtercomponent, to the inner processing chamber; and the filter component comprises a first plate body which can move from left to right, a second plate body which can move from left to right, first sieveholes formed in the first plate body and second sieve holes formed in the second plate body. By adopting the equipment provided by the invention, the filter component is designed to be two plate bodies, and the two plate bodies can independently move back and forth, so that the condition that the plate bodies are blocked is effectively avoided, and the fault rate is low; and in addition, the blocked first plate body can be rapidly dredged without disassembling the filter component for independent cleaning, so that operation is simple and convenient, and the time and the labor are saved.

Owner:常成友

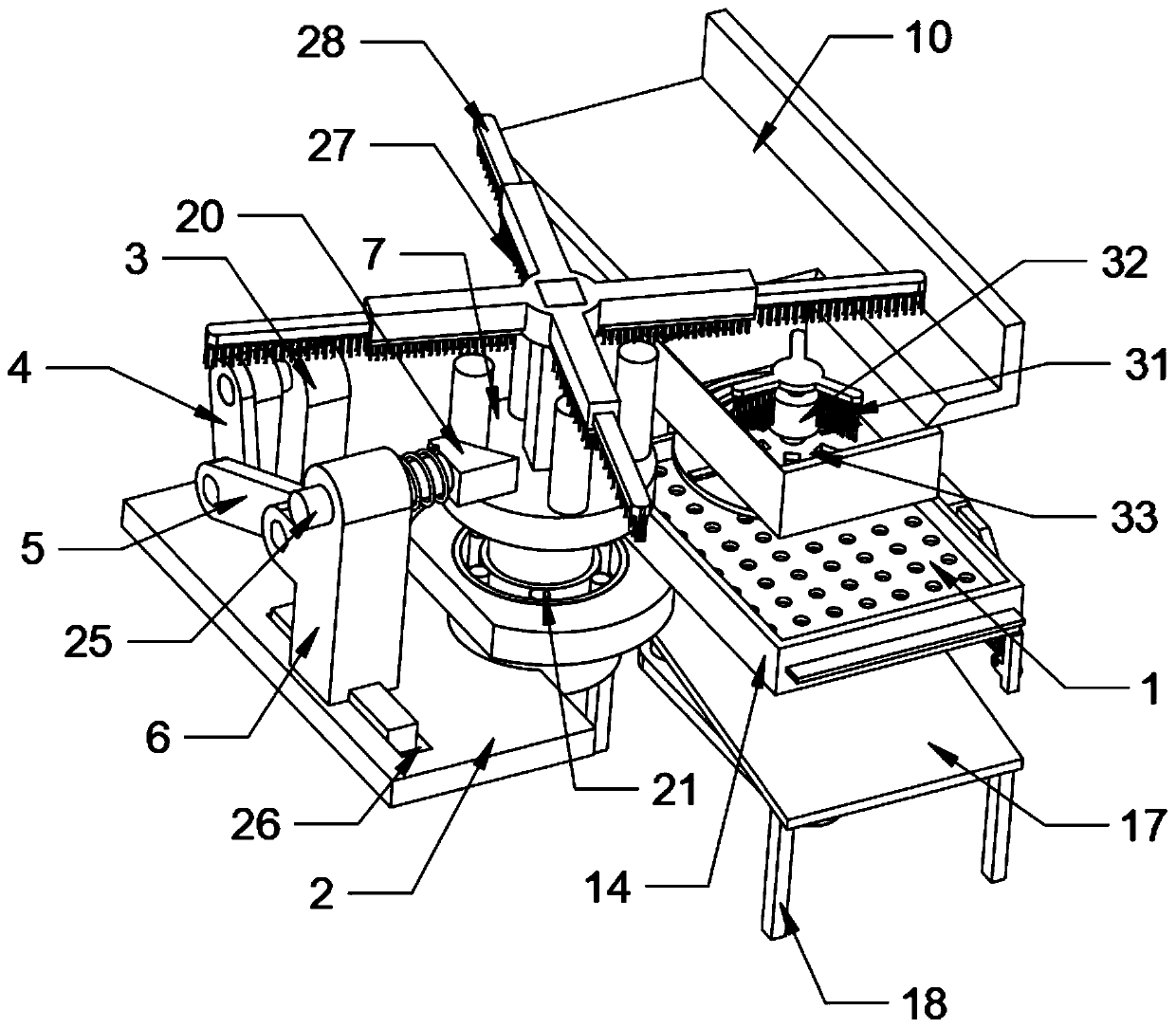

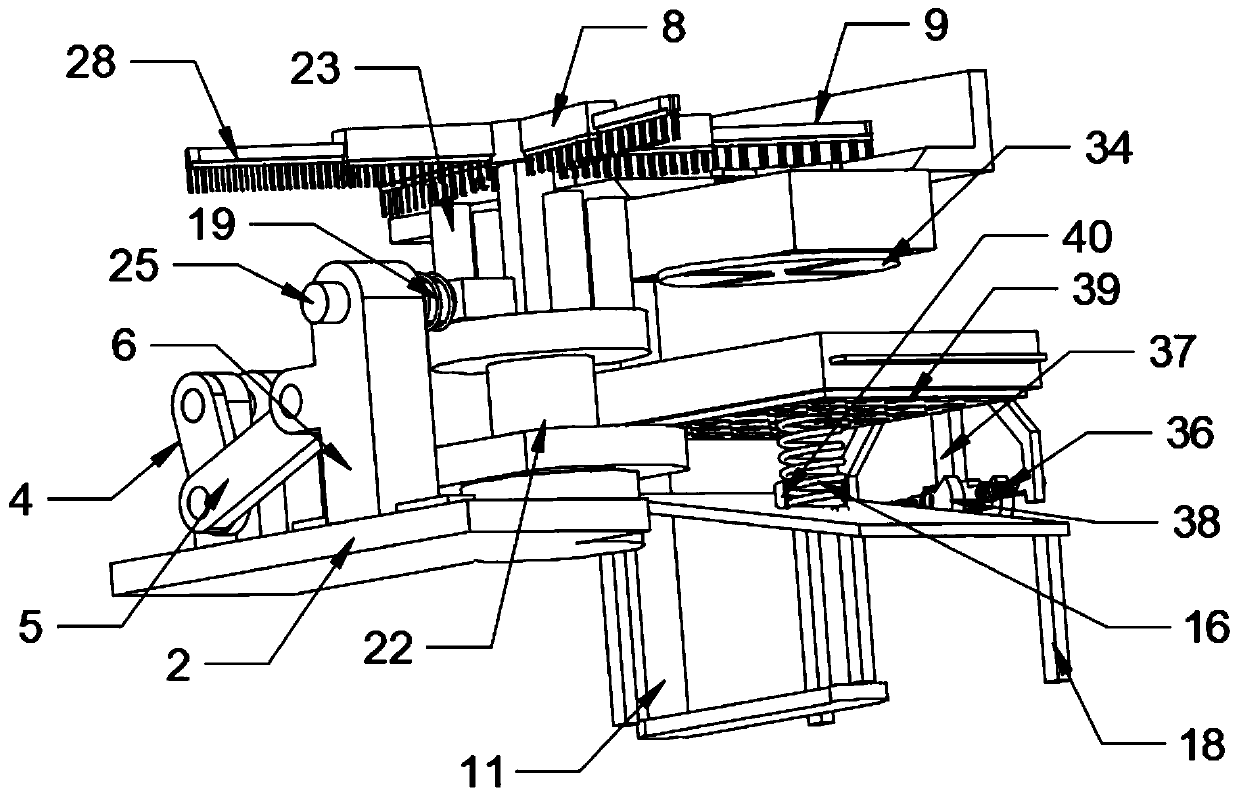

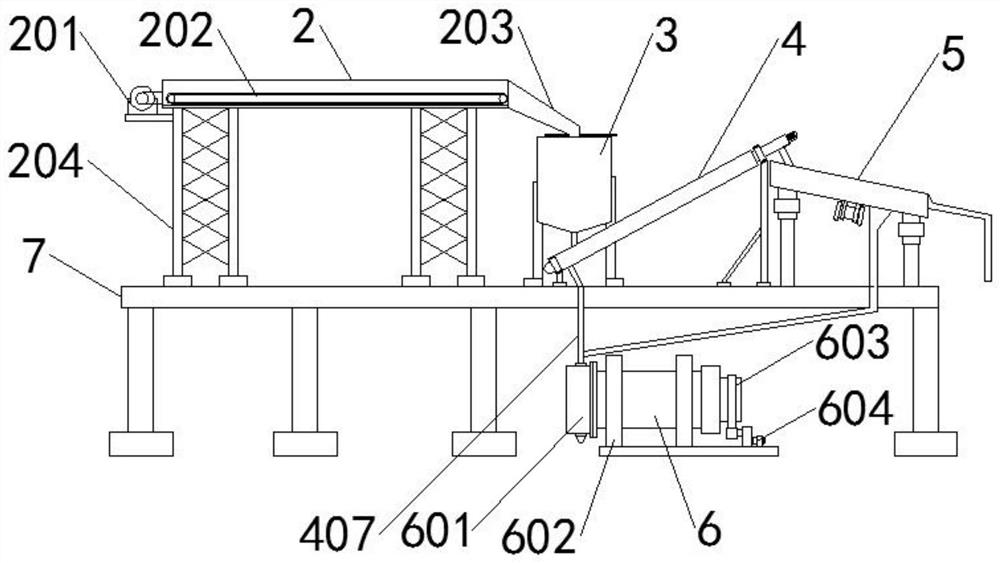

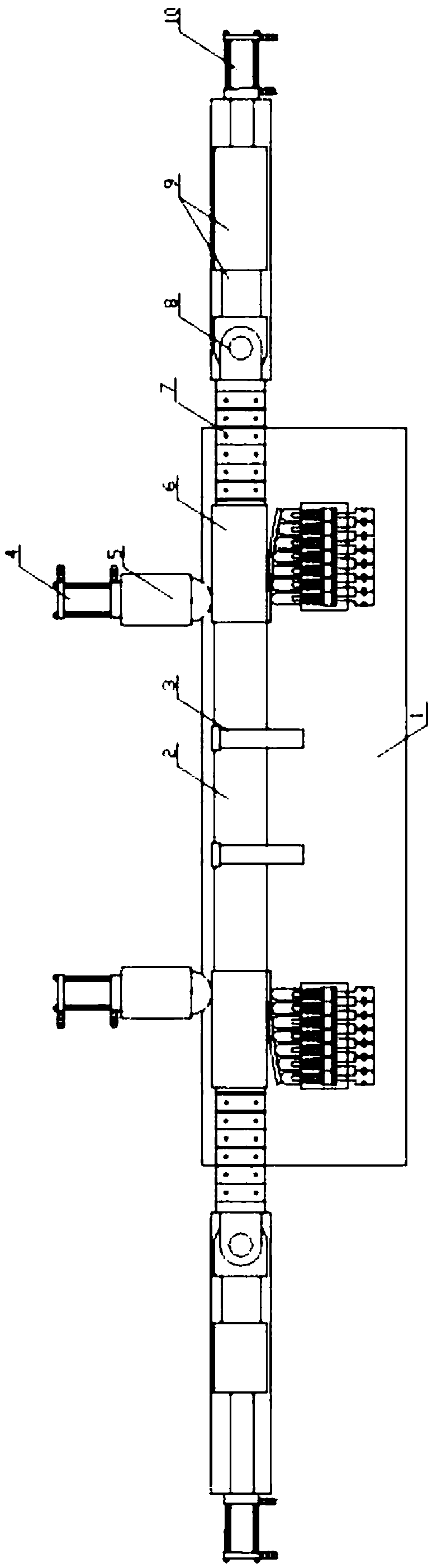

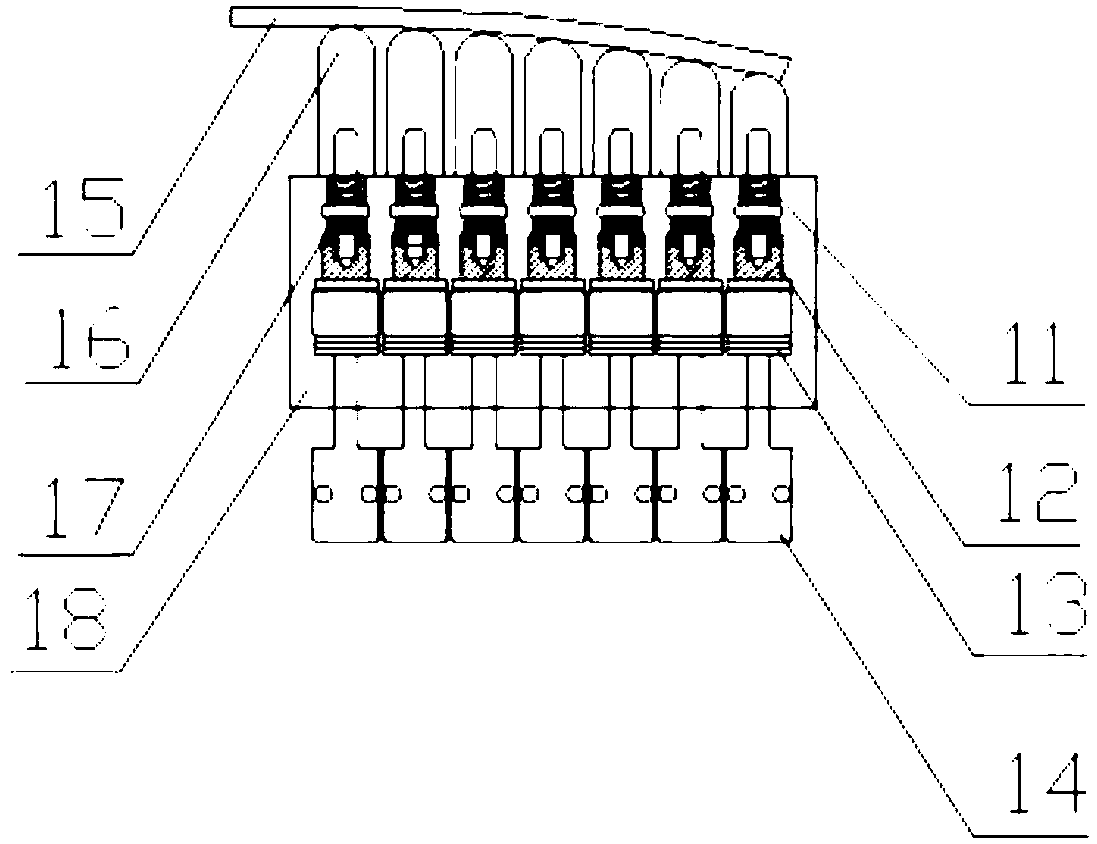

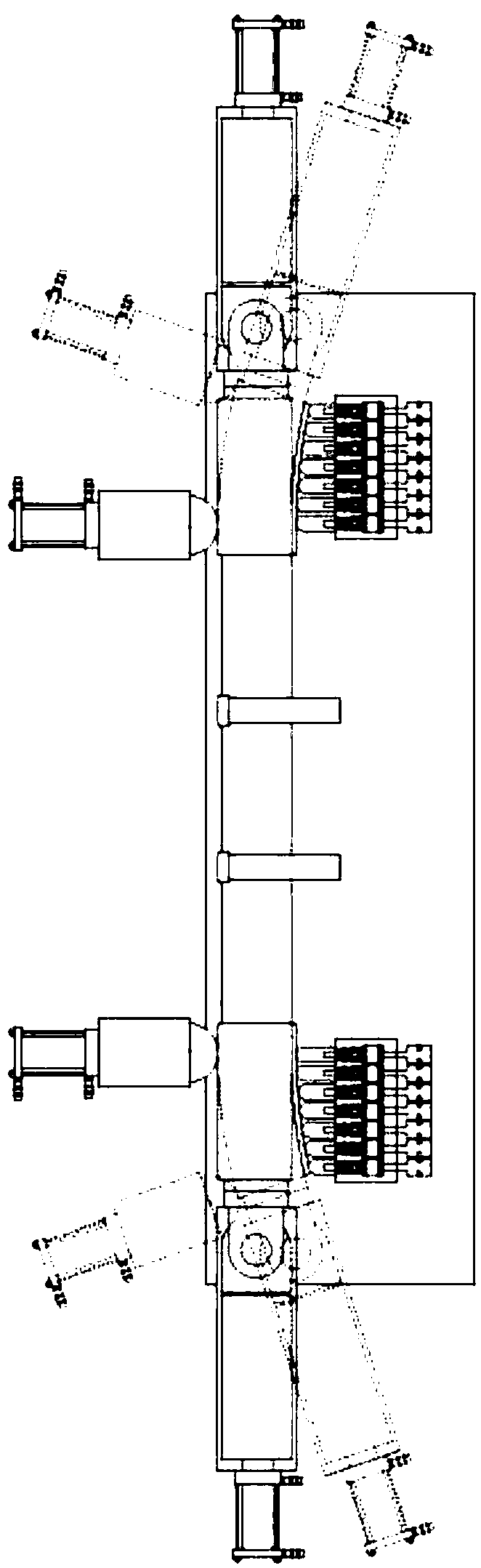

Ultrasonic-assisted vibration multi-point mold support rotary forming device

ActiveCN109465317AImprove stabilityRaise the forming limitShaping toolsVehicle componentsUltrasonic assistedTransducer

The invention discloses an ultrasonic-assisted vibration multi-point mold support rotary forming device and belongs to the technical field of metal profile bending forming technology. The device is mainly composed of a work table, a profile, a profile clamp, a pressure roller hydraulic transmission and force application device, a pressure roller, a guard plate, a core mold, a hinge device, a sleeve, a core mold hydraulic transmission device, a spring, an amplitude-change pole, a transducer, an ultrasonic wave generation device, an elastic pad, a mold-free multi-point mold, a spring damper anda mold base. The forming shape of the mold-free multi-point mold can be adjusted according to practical machining requirements, and the frequency and amplitude of the ultrasonic wave generator can beadjusted according to the materials and machining size of the practically-machined profile so as to achieve the purpose of assisted forming. A bending forming device and the ultrasonic-assisted vibration multi-point support mold technology are combined together, a traditional profile bending forming device is improved, the profile forming stability is improved, the forming range is expanded, and the product quality is improved.

Owner:吉林大学重庆研究院

Energy saving hot wind furnace heating equipment

InactiveCN109059295AAchieve vibration effectEliminate vibrationFluid heatersDispersed particle filtrationCombustion chamberFlue gas

The invention relates to an energy saving hot wind furnace heating equipment which includes a wind furnace shell body. A blower is fixedly installed on the outside of the wind furnace shell body, thetop of the blower is fixedly provided with a feeding port, the top of the feeding port is fixedly provided with an observation port, and a heat preservation board is fixedly installed with the insideof the wind furnace shell body. The heat preservation board is provided with a combustion chamber, one end of the combustion chamber is provided with a flue gas outlet, one side of the combustion chamber is fixedly provided with a shock absorption mechanism, one side of the shock absorption mechanism is fixedly provided with a dust removal device, the upper part of the wind furnace shell body is fixed with a smoke outlet, and one end of the wind furnace shell body is fixed with a hot wind outlet. According to the energy saving hot air furnace heating equipment, a dust removal net is used for absorbing dust generated by fuel combustion, after absorbing a certain amount of the dust, under action of a driving motor, and the dust removal net vibrates through the action of a eccentric wheel, aconnecting guide rod, a spring connecting plate and a telescopic spring to vibrate the dust removal net absorbed.

Owner:金双悦

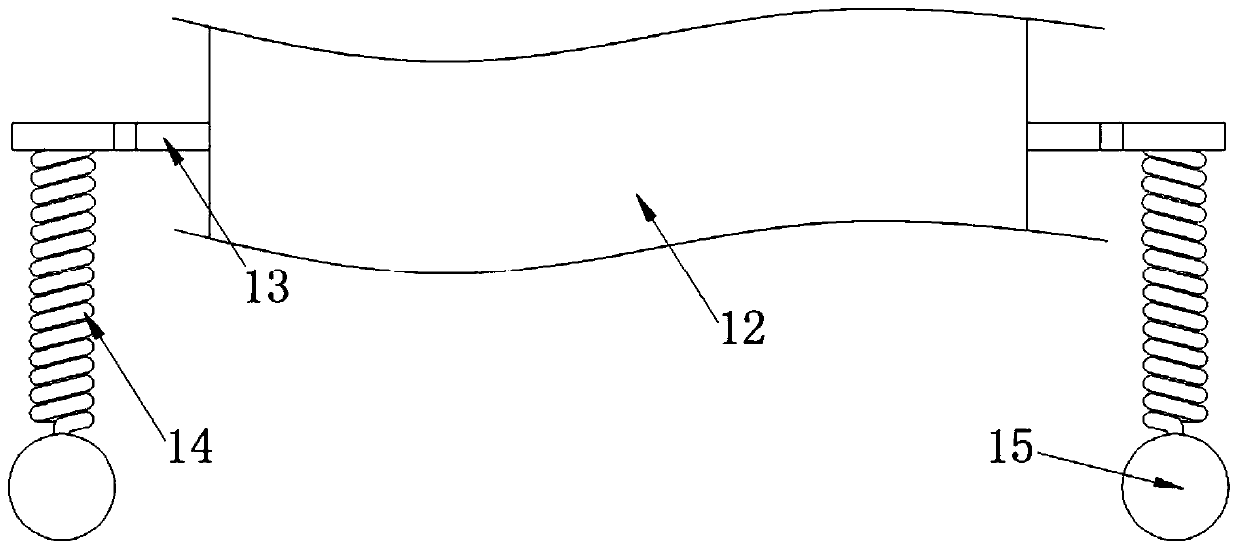

Straw briquetting machine material receiving table capable of vibrating

The invention discloses a straw briquetting machine material receiving table capable of vibrating. The straw briquetting machine material receiving table comprises a compression roller, a main shaft,a material receiving table, a first spring, a rack, a first movable rod, a fixing sleeve, a first piston, an abnormal-diameter U-shaped pipe, a second piston, a second movable rod, a motor, a tuning fork, a second spring and a pressing block. According to the straw briquetting machine material receiving table capable of vibrating, the tuning fork and the first movable rod are cooperated; when thestraw briquetting machine works, the motor vibrates, the vibration of the motor is transferred to the tuning fork, the tuning fork vibrates and drives the pressing block to vertically vibrate, and thepressing block beats the second movable rod; through the function of the abnormal-diameter U-shaped pipe, the first movable rod upwards moves to upwards support the material receiving table; when thematerial receiving table moves to a highest point, the material receiving table downwards moves due to the function of gravity; through one series of transmission, the second movable rod rises, and when the second movable rod rises to a certain height, the pressing block can beat the second movable rod; finally, the above action is carried out back and forth, the material receiving table carriesout vertical reciprocating vibration, and an effect of vibration can be achieved.

Owner:台州壹品工业设计有限公司

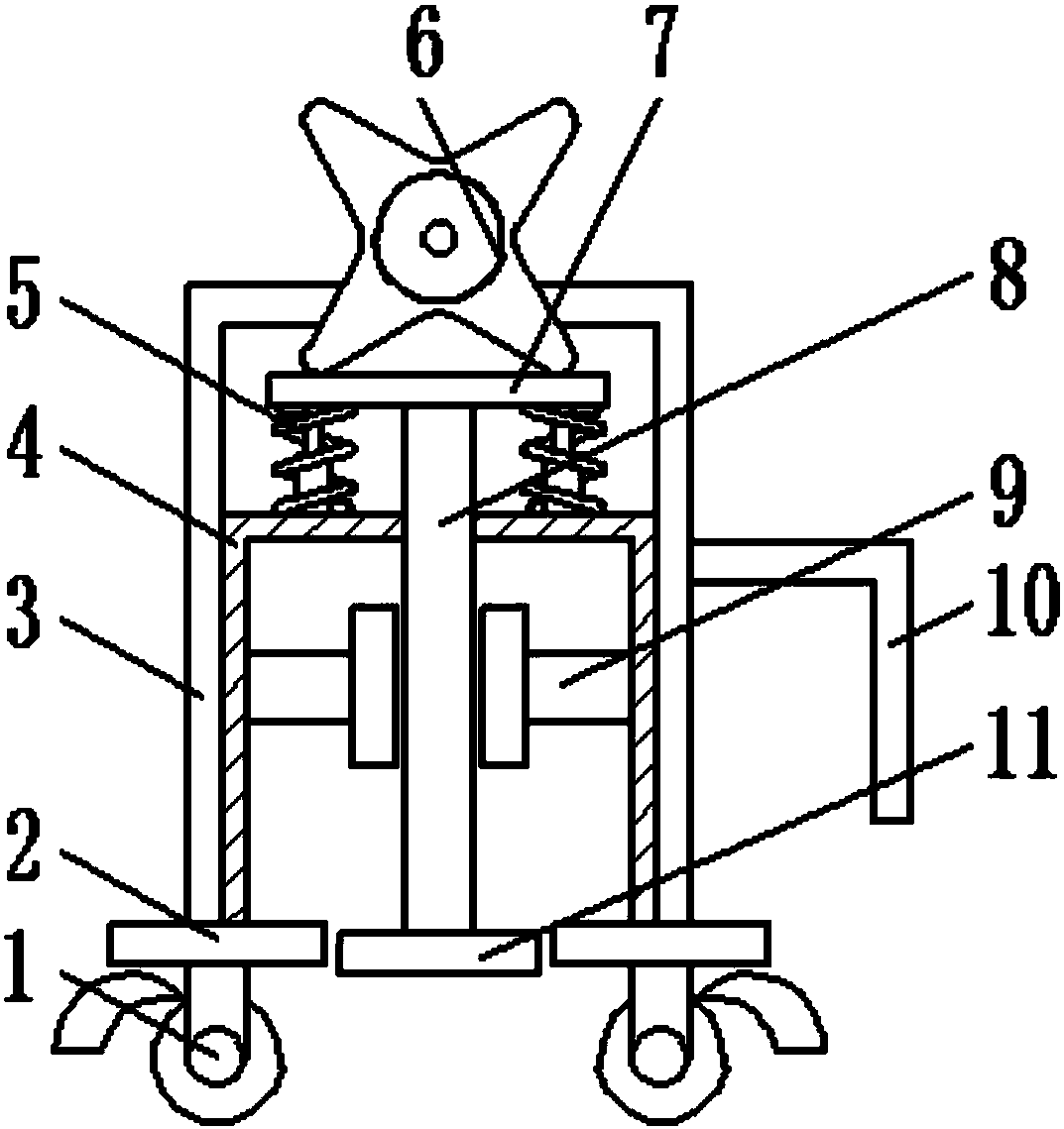

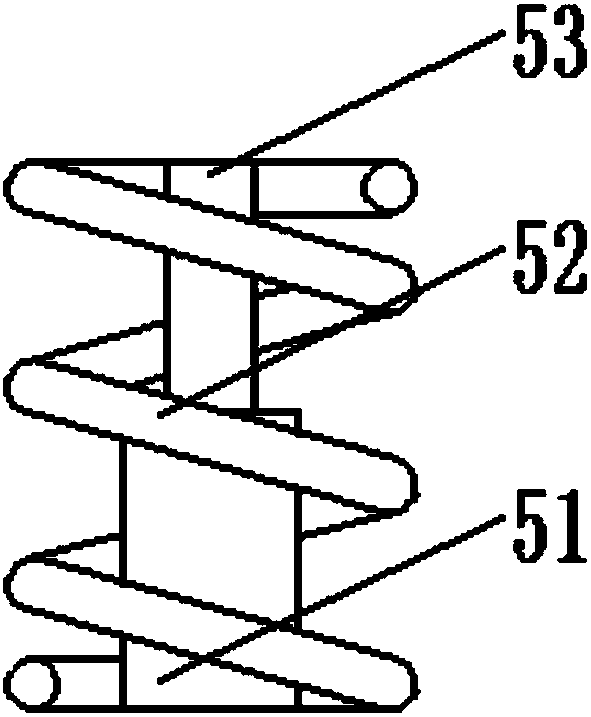

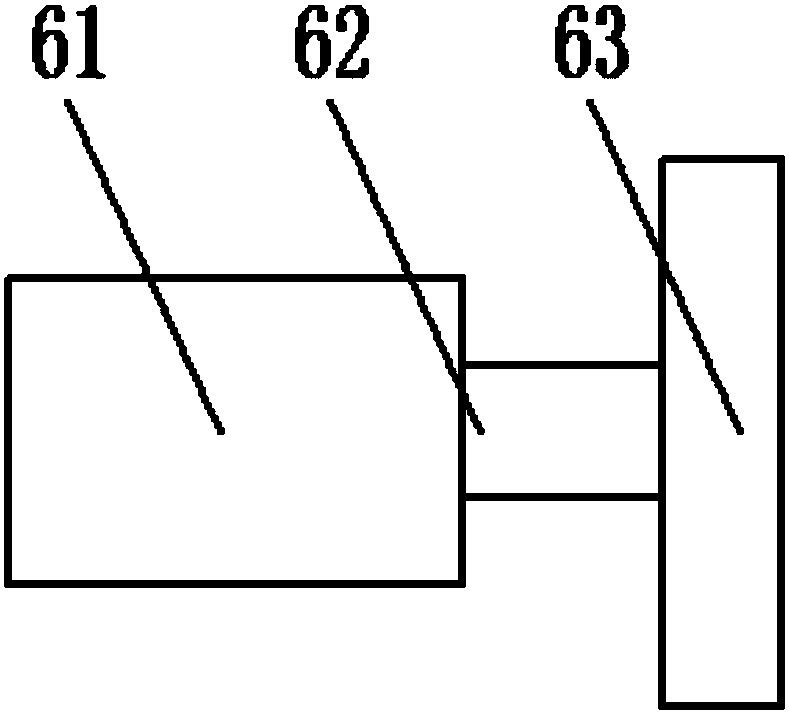

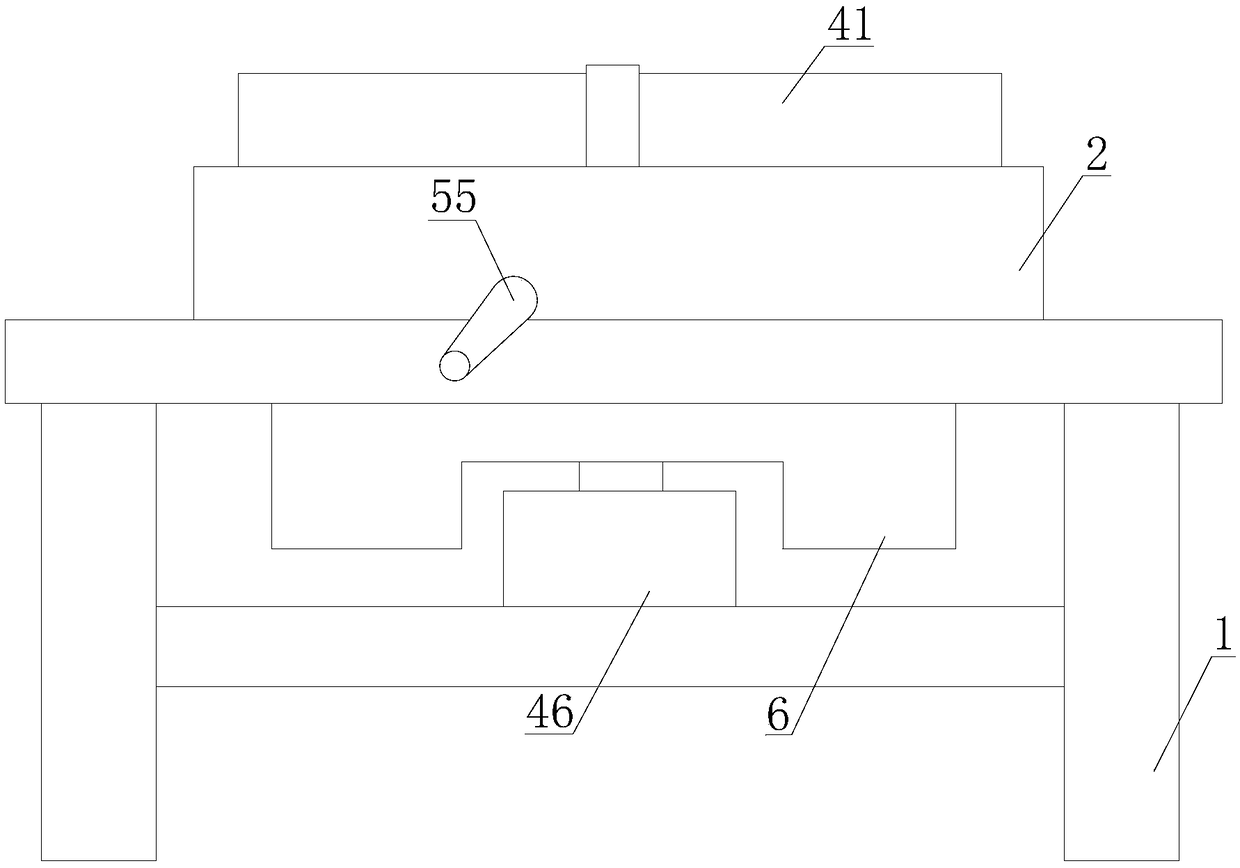

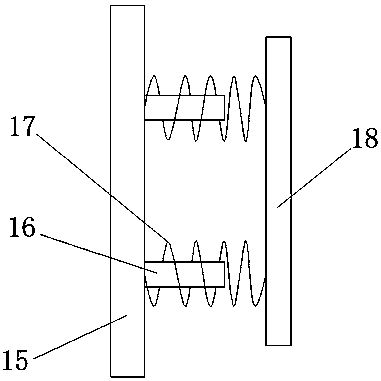

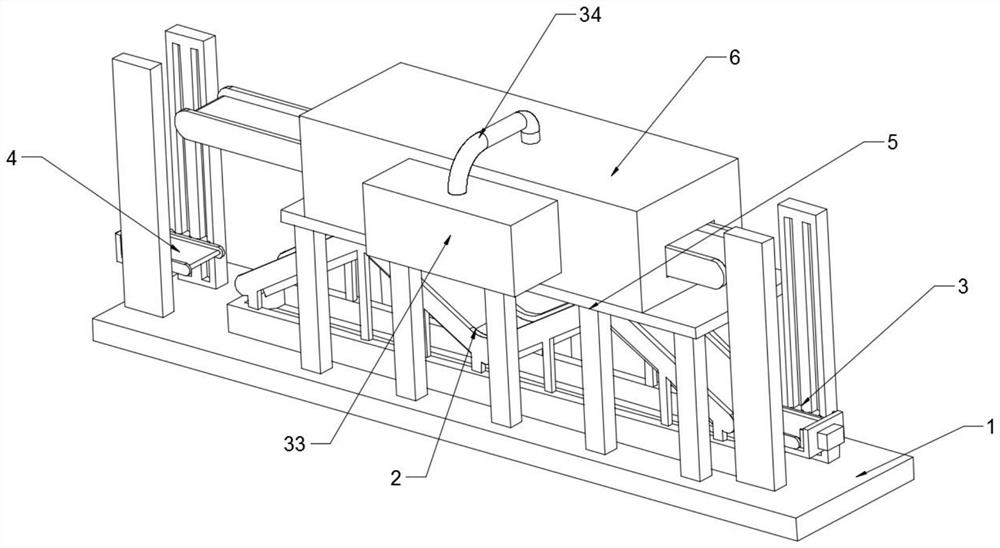

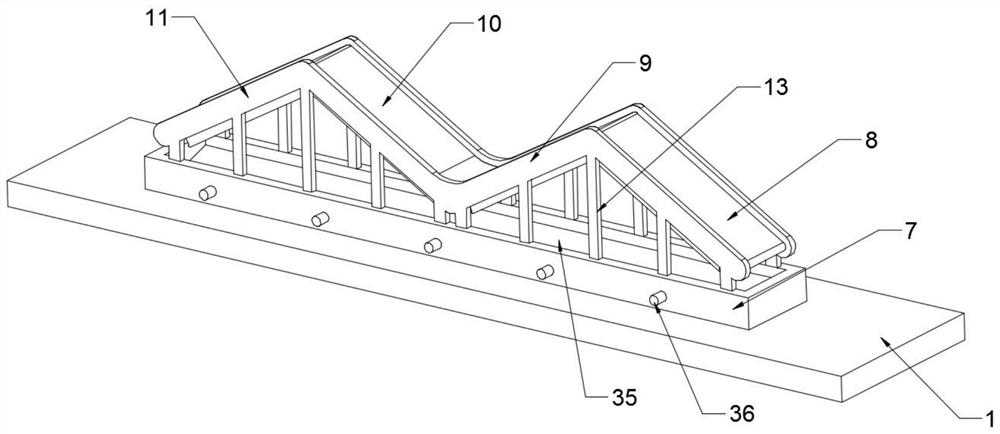

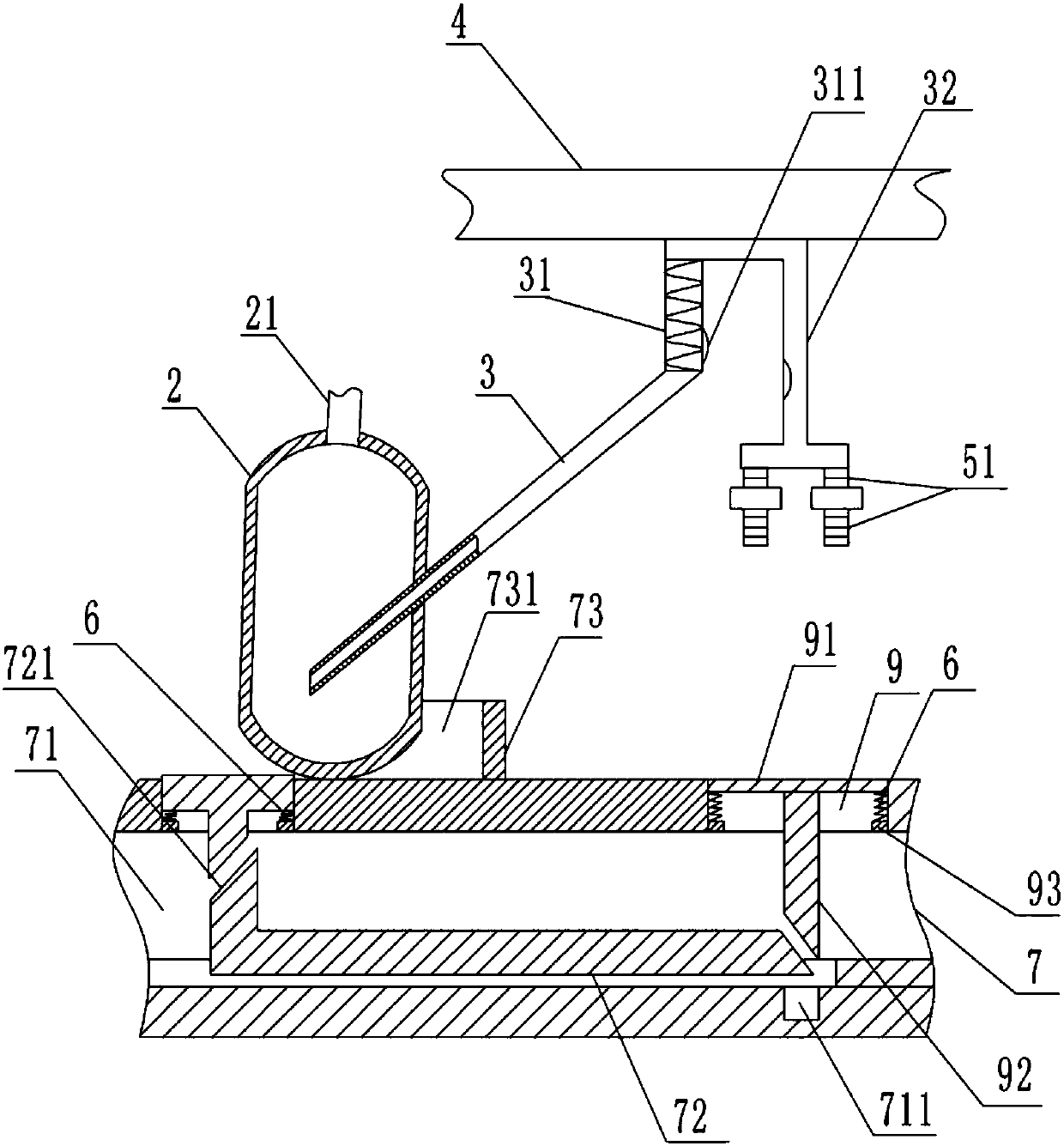

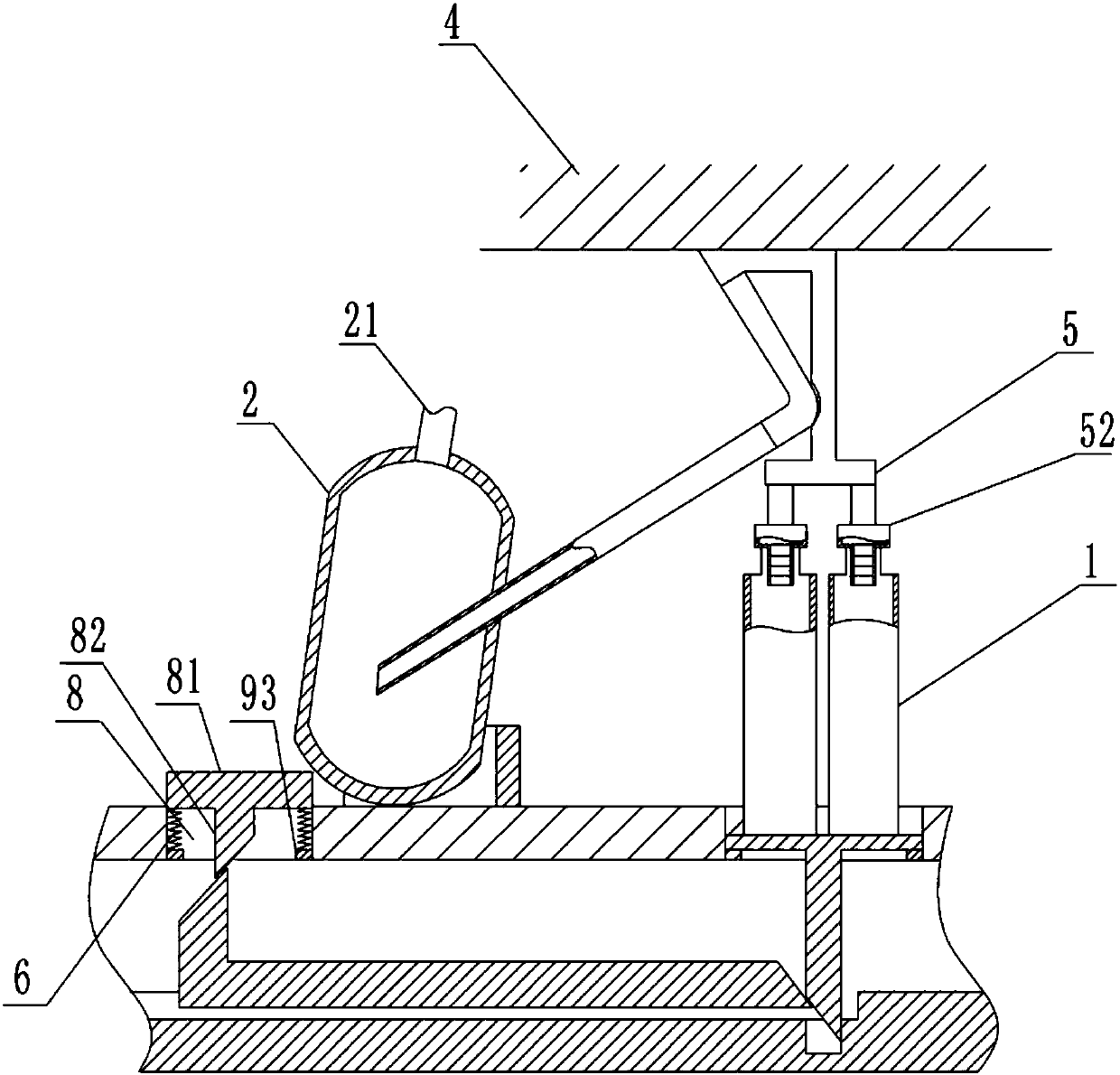

A device for martial arts single-leg balance force training

The invention belongs to the technical field of balance force training, and discloses a device for martial arts single-leg balance force training. The device comprises a bottom plate, the bottom plateis provided with a groove, a motor is installed in the groove, an output end of the motor is connected with a screw rod, the screw rod is in threaded connection with nuts, the top of each nut is fixedly provided with a connecting rod, each connecting rod is sleeved with a spring, the bottom of each spring is fixed on the corresponding connecting rod, a transverse plate is fixedly arranged at thetops of the springs, the connecting rods support the transverse plate in the free state of the springs, and the screw rod is fixedly provided with a cam for jacking the transverse plate from the connecting rods; an air cylinder is installed on the transverse plate, and an output end of the air cylinder is connected with a single-leg pile. The device additionally has a training function to meet therequirement for training difficulty of martial arts single-leg balance force.

Owner:JISHOU UNIVERSITY

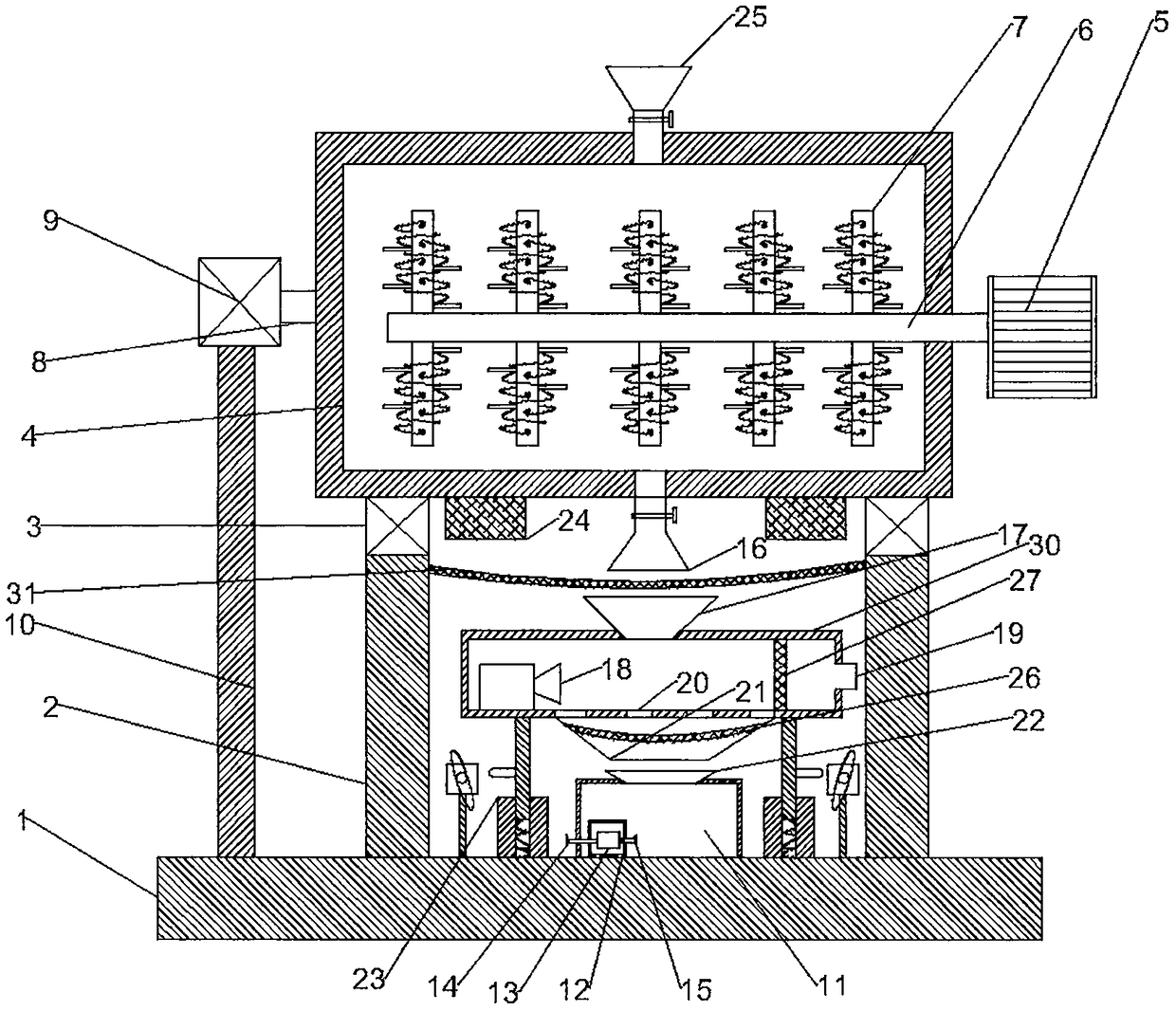

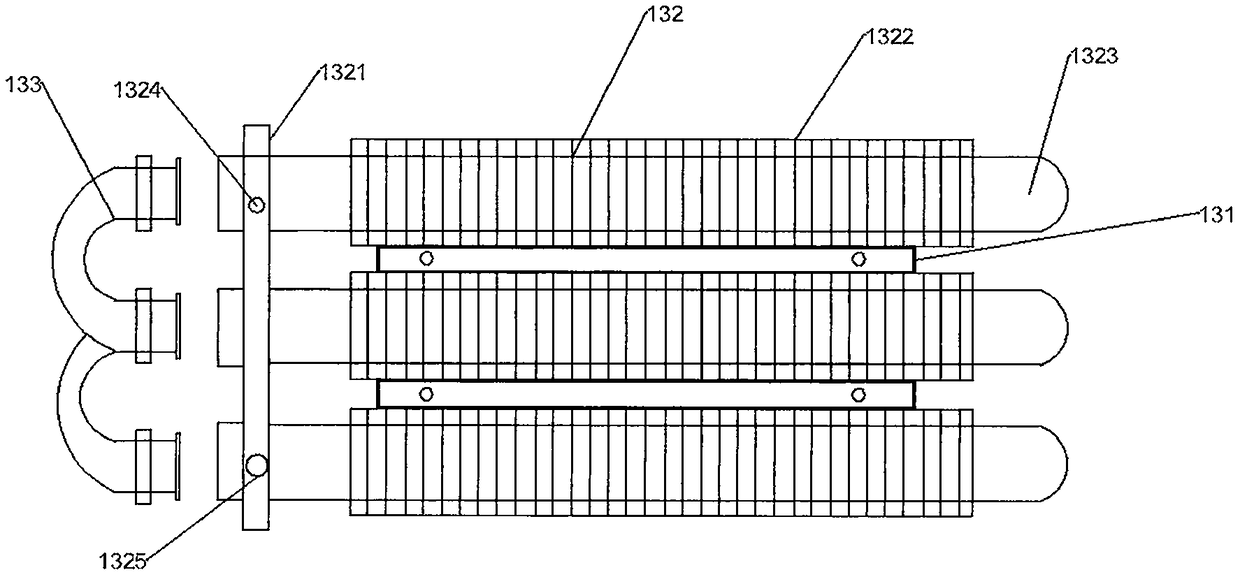

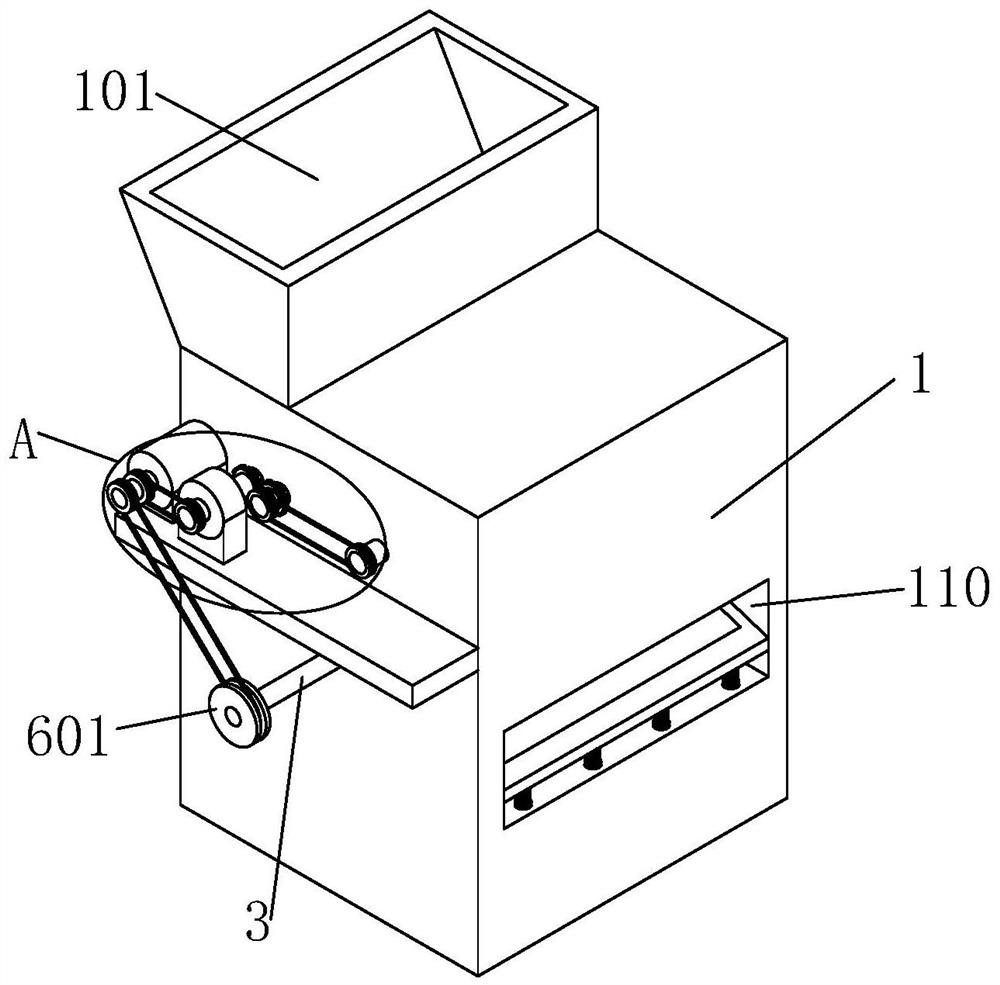

Coal fine crushing mechanism for coal-fired power generation system

InactiveCN111804380AImprove screening effectPrevent stackingSievingScreeningElectric machineDrive shaft

The invention discloses a coal fine crushing mechanism for a coal-fired power generation system. The mechanism comprises a box body, wherein the top of the box body is provided with a feed inlet, a support plate is welded on the side wall of the box body, a motor is fixedly connected to the top of the support plate, the output end of the motor is fixedly connected with a main shaft, the outer surfaces of a first drive shaft and a second drive shaft are respectively fixedly connected with a first crushing roller and a second crushing roller, the front of the box body is provided with a first discharge port, a fixed frame is arranged obliquely inside the box body, a screen is fixedly connected to the inner wall of the fixed frame, the outer surface of the main shaft is provided with a thirdtransmission assembly and is in transmission connection with two vibration blocks through the third transmission assembly, and the back of the box body is provided with a second discharge port. The coal fine crushing mechanism for the coal-fired power generation system has the beneficial effect that the provided third transmission assembly drives the vibration blocks to move up and down, and drives the screen to vibrate up and down, thereby avoiding the accumulation of coal on the upper surface of the screen.

Owner:陈秋梅

An automatic screening device for construction sand and gravel

ActiveCN111451127BAvoid stackingSpeed up the fallSievingScreeningElectric machineryStructural engineering

The invention discloses an automatic screening device for construction sand and gravel, which includes a sieve plate and a frame, a first motor is installed above the frame, and a first transmission rod is fixedly connected to the output end of the first motor. The end of the first transmission rod away from the first motor is rotatably connected with a second transmission rod, and the end of the second transmission rod away from the first transmission rod is rotatably connected with a slider, and the slider is slidably connected with the frame, and the slider An intermittent mechanism is slidably connected inside the block, and a turret is fixedly connected above the intermittent mechanism, and a brushing device is fixedly connected to the surface of the turret, and a baffle is placed below the brushing device, and the baffle is The lower part is fixedly connected with a fixed column, and the fixed column is fixedly connected with the ground. The upper surface of the baffle plate is provided with a blanking hole, and a feeding device is installed inside the blanking hole. There is a sieve frame, and the surface of the sieve frame is clamped with a sieve plate. This automatic screening device has adaptability, high degree of automation, can improve the efficiency of screening materials, and has a simple structure and strong practicability.

Owner:湖南砼创物联科技有限公司

Machine tool capable of realizing rapid vibration

The invention relates to the technical field of machinery, and discloses a machine tool capable of realizing rapid vibration. The machine tool capable of realizing rapid vibration comprises an outer box, wherein a base is fixedly installed at the bottom of the outer box; two fixed rods are fixedly installed at the top of the base and in the outer box; movable columns are arranged at the opposite sides of each fixed rod; a vibration plate is fixedly installed at the tops of the movable columns; two fixed plates are connected to the opposite sides of the movable columns; a movable groove is formed in the opposite sides of the two fixed plates and the opposite sides of the two fixed rods separately; and a movable block is clamped between the two fixed plates. According to the machine tool capable of realizing rapid vibration, through arrangement for a fixing ring on a first rotary shaft, the first rotary shaft can be supported; and through arrangement for a vertical gear on the first rotary shaft and engaged with a cross gear, the rotation of the vertical gear can be driven during the rotation of a motor, so that the problem that the efficiency of screening goods and materials cannotbe increased due to a too low speed of the vibration motor utilizing a spring, is effectively solved.

Owner:李丽倩

Snail meat processing and quick-freezing device facilitating clearing of inner wall ice

PendingCN113970223AAvoid stickingImprove quick freezing effectLighting and heating apparatusStationary refrigeration devicesAnimal scienceWater storage tank

The invention discloses a snail meat processing and quick-freezing device facilitating clearing of inner wall ice. The device comprises a base, a water filtering mechanism mounted above the base, a first lifting mechanism and a second lifting mechanism, wherein the first lifting mechanism and the second lifting mechanism are respectively arranged on two sides of the water filtering mechanism. A supporting seat is arranged on the outer side of the water filtering mechanism. A quick-freezing mechanism is fixedly arranged on the supporting seat, the quick-freezing mechanism is arranged above the water filtering mechanism, and a water storage tank is fixedly arranged on the base. The water filtering mechanism is arranged on the base, the water storage tank is arranged at the bottom of the water filtering mechanism, the quick-freezing mechanism is fixedly arranged above the water filtering mechanism, and due to the special structure of a bent wave crest shape of a chain scraper conveyor in the water filtering mechanism, when a containing vessel with snail meat passes through the water filtering mechanism, the dehydration work of the snail meat and the containing vessel is completed to a certain extent, and the situation that the snail meat and the containing vessel are tightly attached and bonded in the subsequent quick-freezing process of the snail meat, and consequently the snail meat is inconvenient to take in the subsequent process can be avoided.

Owner:高邮市健龙蜗牛养殖科技有限公司

Vacuum pump buffer tank

ActiveCN107939647AImprove buffering effectEasy to bendPositive displacement pump componentsPumpsBuffer tankEngineering

The invention relates to the technical field of vacuum pumps, in particular to a vacuum pump buffer tank. The vacuum pump buffer tank comprises buffer pipelines and a buffer tank body which inclines downwards facing gas tanks under the gravity of the gas tanks, the upper portion of the buffer tank body is provided with a gas outlet pipe, the buffer pipelines comprise a first pipeline, a second pipeline and a third pipeline, one end of the first pipeline inclines downwards and stretches into the buffer tank body, the second pipeline is an elastic extension pipe, the side wall of the elastic extension pipe is provided with a first magnet, the other end of the first pipeline is connected with one end of the elastic extension pipe, the other end of the elastic extension pipe is connected withone end of the third pipeline, the upper end of the third pipeline is provided with a fixing portion used for fixing the third pipeline, the side, close to the elastic extension pipe, of the third pipeline is further provided with a second magnet which is in mutual attraction with the first magnet, and the second magnet is further provided with vibrating pieces used for stretching into the third pipeline. By means of the vacuum pump buffer tank, gases can be mixed in the process of vacuuming the gas tanks, and the gases can further be buffered for many times.

Owner:NANTONG BEIKE VACUUM MACHINERY CO LTD

Multistage crushing type medical waste disposal device

InactiveCN111998355AEasy to controlEasy to operateMedical waste disposalIncinerator apparatusUv disinfectionMedical waste

The invention discloses a multistage crushing type medical waste disposal device, and belongs to the technical field of medical waste disposal. The technical scheme is that the device comprises a treatment box, a crushing cavity, a conveying cavity, a fixed cylinder and a rotary screen, wherein the top end of the interior of the treatment box is fixedly connected with a plurality of uniformly distributed ultraviolet disinfection lamps; disinfectant nozzles are arranged between every two adjacent ultraviolet disinfection lamps, a V-shaped filter belt is arranged below the multiple ultraviolet disinfection lamps, garbage enters the treatment box and falls above the filter belt, and the filter belt rotates, so that the garbage is continuously turned over above the filter belt; and the ultraviolet disinfection lamps and the disinfectant nozzles are started, thereby facilitating the overturned garbage for disinfection; and when the garbage is overturned, liquid garbage flows to the lower portion through the filter belt, so that the liquid garbage and solid garbage are separated, and the garbage disinfection treatment efficiency and quality are improved.

Owner:刘贵芳

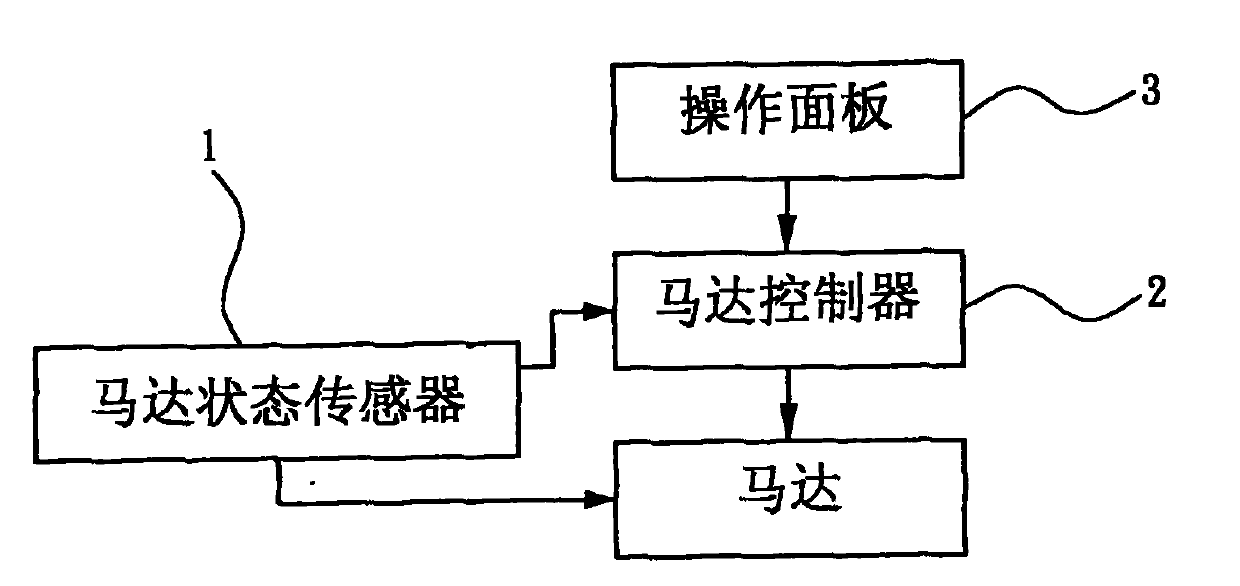

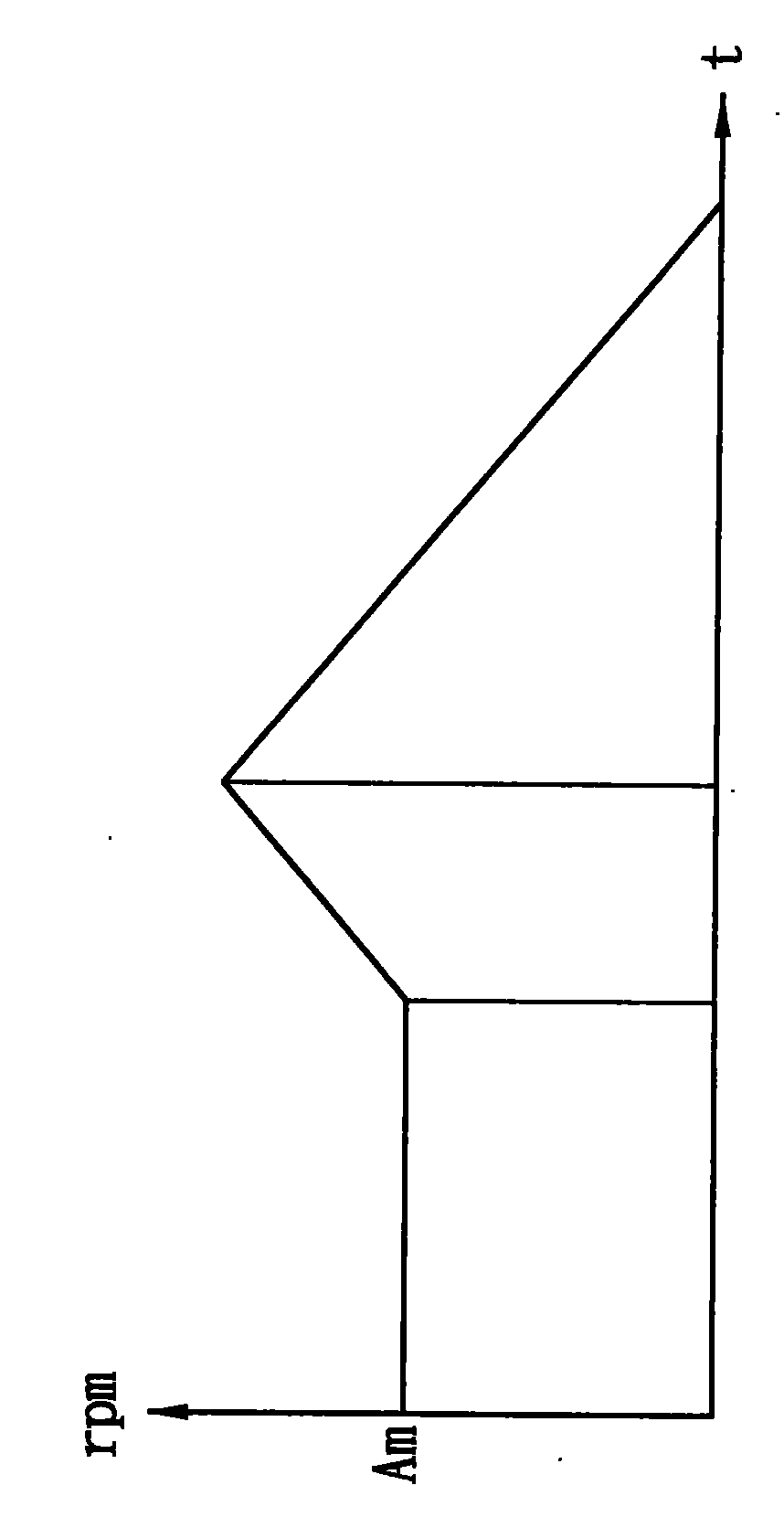

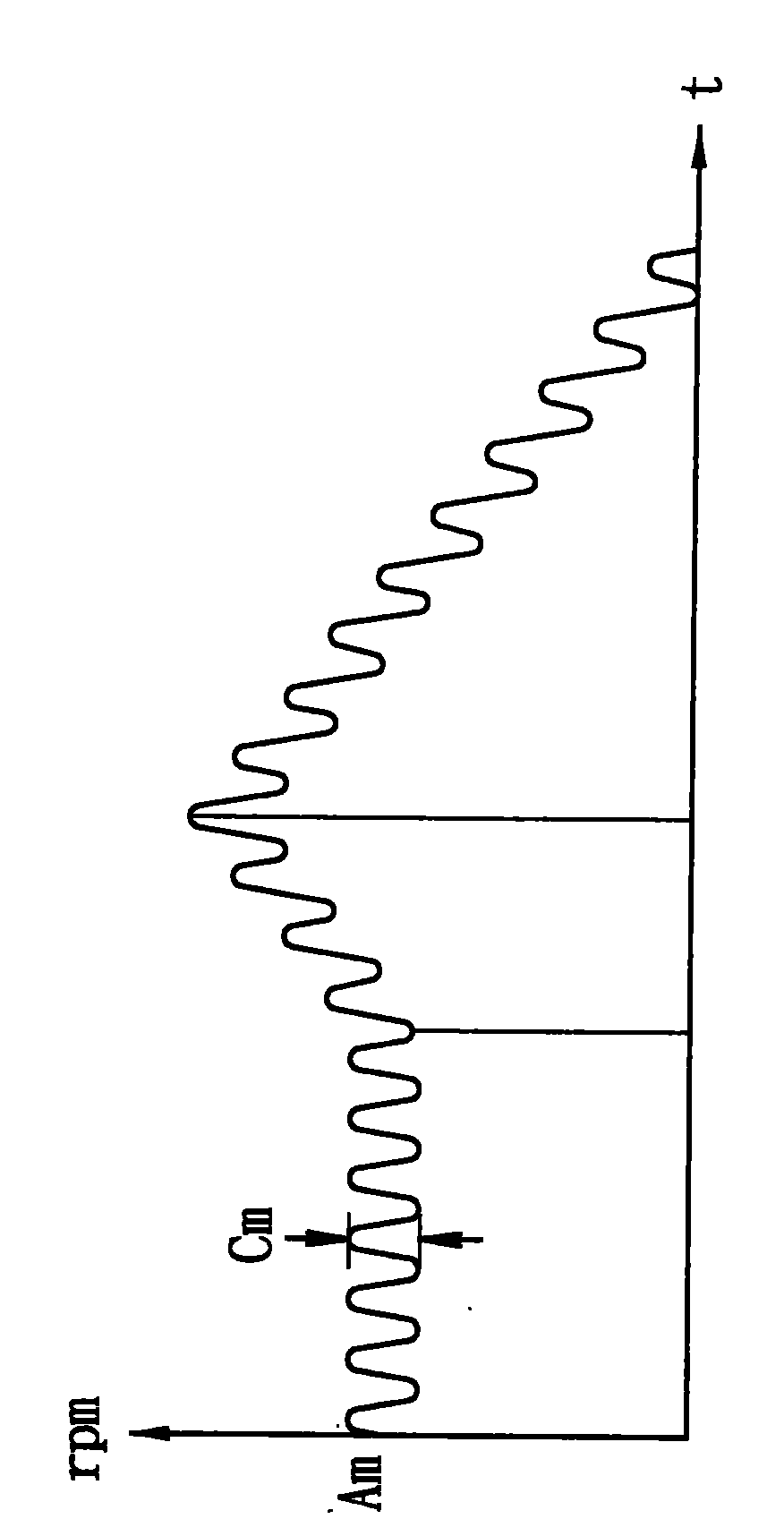

Connecting rod type reciprocating vibration control system

InactiveCN102088267AAchieve vibration effectWith vibration effectDC motor speed/torque controlElectric motor controlVibration controlReciprocating motion

The invention discloses a connecting rod type reciprocating vibration control system. The system comprises a motor state sensor, a motor controller and an operation panel, wherein the motor state sensor is pivoted at a proper position of a motor and is used for sensing the rotation speed of the motor; the motor controller is electrically connected with the motor state sensor and the motor; the motor controller is used for controlling the rotation speed of the motor; and the operation panel is used by a user to set data of the motor controller. Therefore, the motor controller controls the rotation speed of the motor according to the data set by the operation panel; a speed ripple is added when the rotation speed of the motor is set; the rotation speed is affected by means of the speed ripple, so that a speed difference is generated when the motor runs and then the motor has a vibration effect when driving the connecting rod type reciprocating machine table.

Owner:欣麟科技股份有限公司

Shaped glass powder feeding device

ActiveCN108031622BAvoid the problem of accumulation on the concave surface of special-shaped glassPowder evenlyLiquid surface applicatorsCoatingsReciprocating motionEngineering

The invention relates to the technical field of surface coating devices, and particularly discloses a special-shaped glass powder feeding device. The device comprises a box body, a vacuum pump, a power mechanism, a working mechanism and a transmission mechanism; the power mechanism comprises a motor, a first gear and a first rack meshed with the first gear, and the middle section of the first rackis provided with a paw for fixing special-shaped glass; the transmission mechanism comprises an L-shaped handle arranged on the first rack and a cylinder body, wherein a first piston is arranged inside the cylinder body in a sliding fit mode, and the free end of the handle is fixedly connected with the first piston; the working mechanism comprises a groove body communicating with the cylinder body and a bearing groove arranged above the groove body, the size of the bearing groove is larger than the size of the special-shaped glass, and the groove body is arranged at the bottom of the box body; and a second piston is arranged in the groove body in a sliding fit mode, and the second piston is fixedly connected with a crank sliding block mechanism for driving horizontal reciprocating motionof the bearing placing groove. According to the technical scheme, the surface of the special-shaped glass can be uniformly coated with powder, and therefore, the device can be widely applied to the powder feeding of the special-shaped glass.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

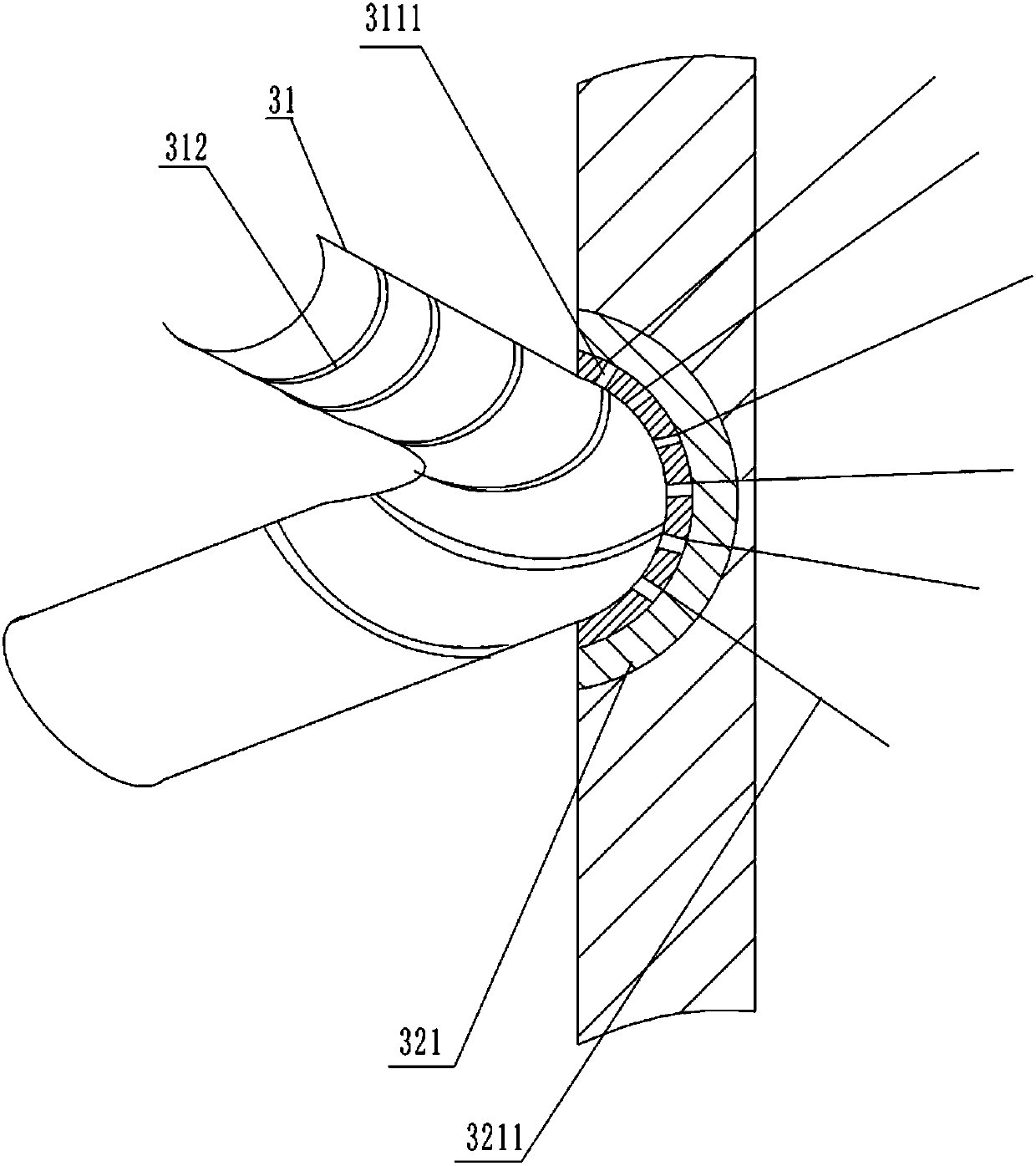

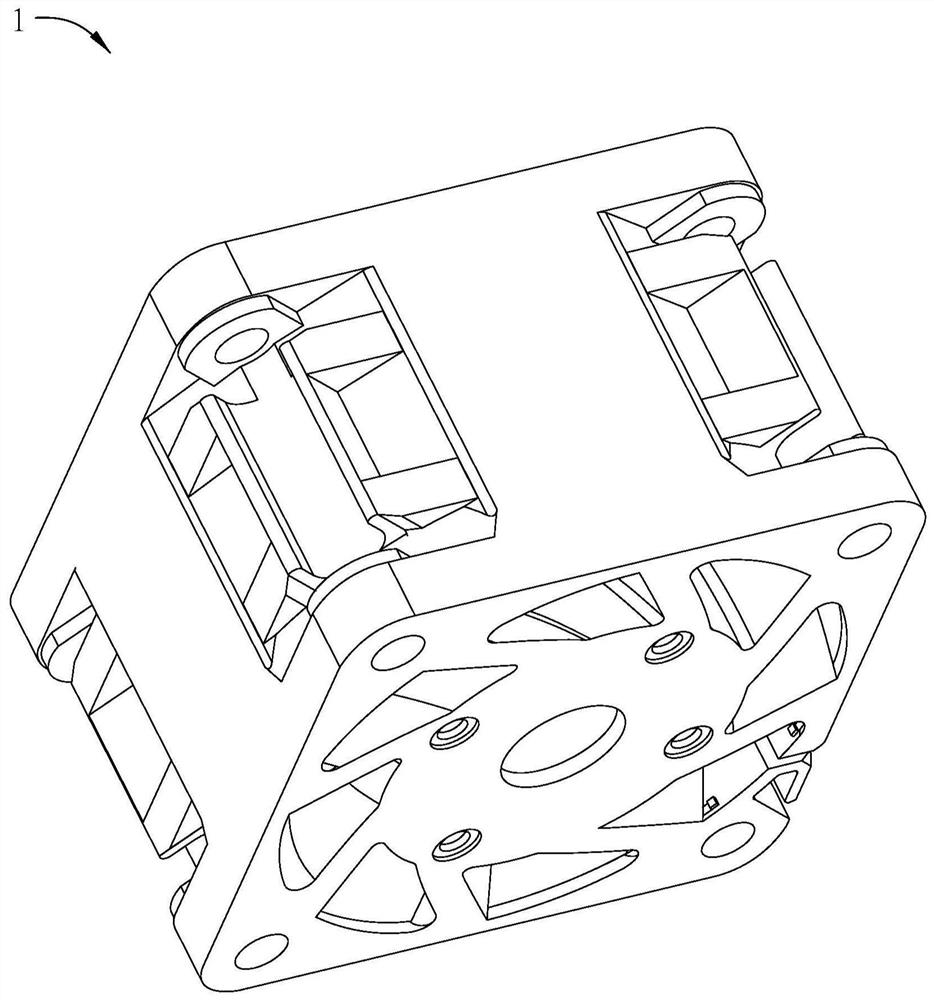

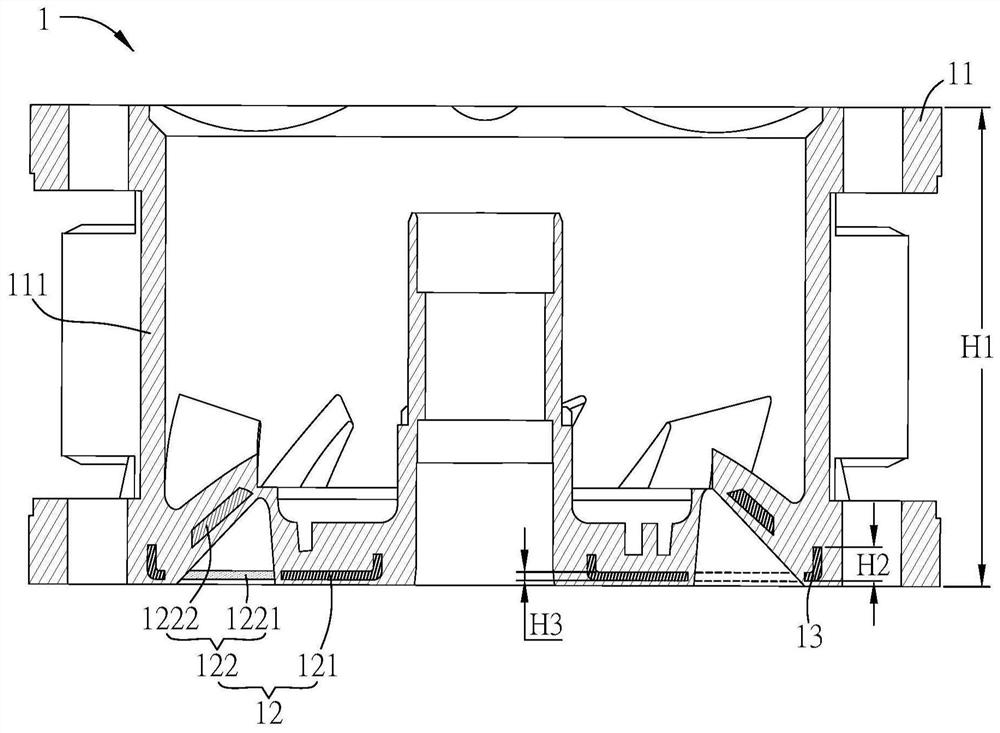

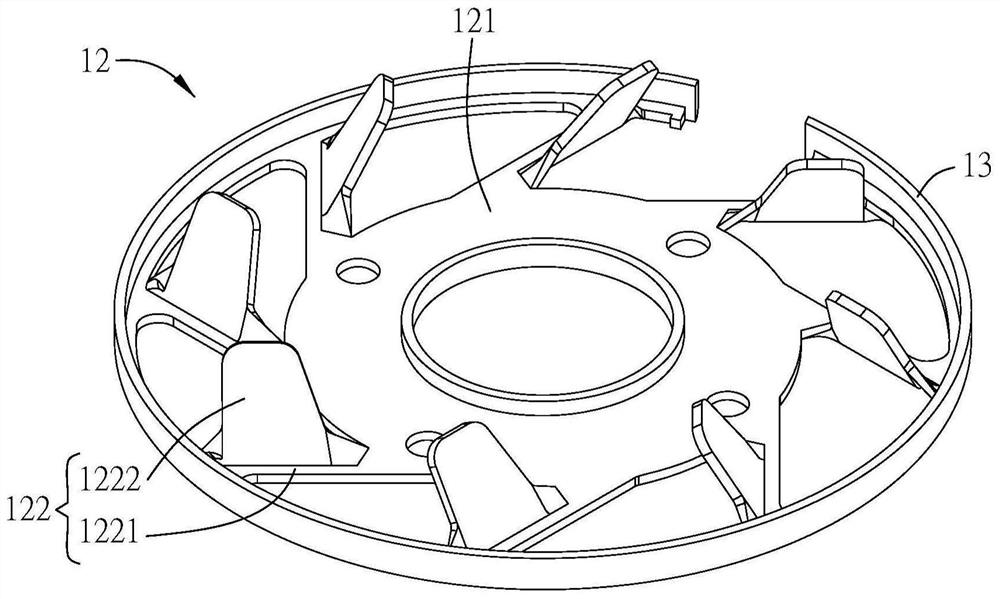

fan frame

ActiveCN109424587BAchieve vibration effectTo achieve the effect of dispersing vibrationPump componentsDigital data processing detailsClassical mechanicsStructural engineering

The invention discloses a fan frame, which comprises a frame body and a metal base. The frame body includes a frame wall, and the metal base includes a central part and a plurality of stator blades. The plurality of vanes extend radially from the center and are connected to the frame wall, and the material of the frame body is different from that of the vanes. The invention also discloses a fan frame, which includes a base and a frame body. The frame body includes a metal frame wall and a plurality of stationary vanes. The plurality of stationary vanes extend radially inward from the metal frame wall and are connected to the base, and the material of the frame body is different from that of the stationary vanes. The invention also discloses a fan frame, which includes a frame body, a base and a plurality of stator blades. The frame body includes frame walls. One end of the plurality of stationary vanes is connected to the base, and the other end is connected to the frame wall, wherein at least a part of the plurality of stationary vanes is made of metal, and the material of the frame body is different from that of the stationary vanes.

Owner:DELTA ELECTRONICS INC

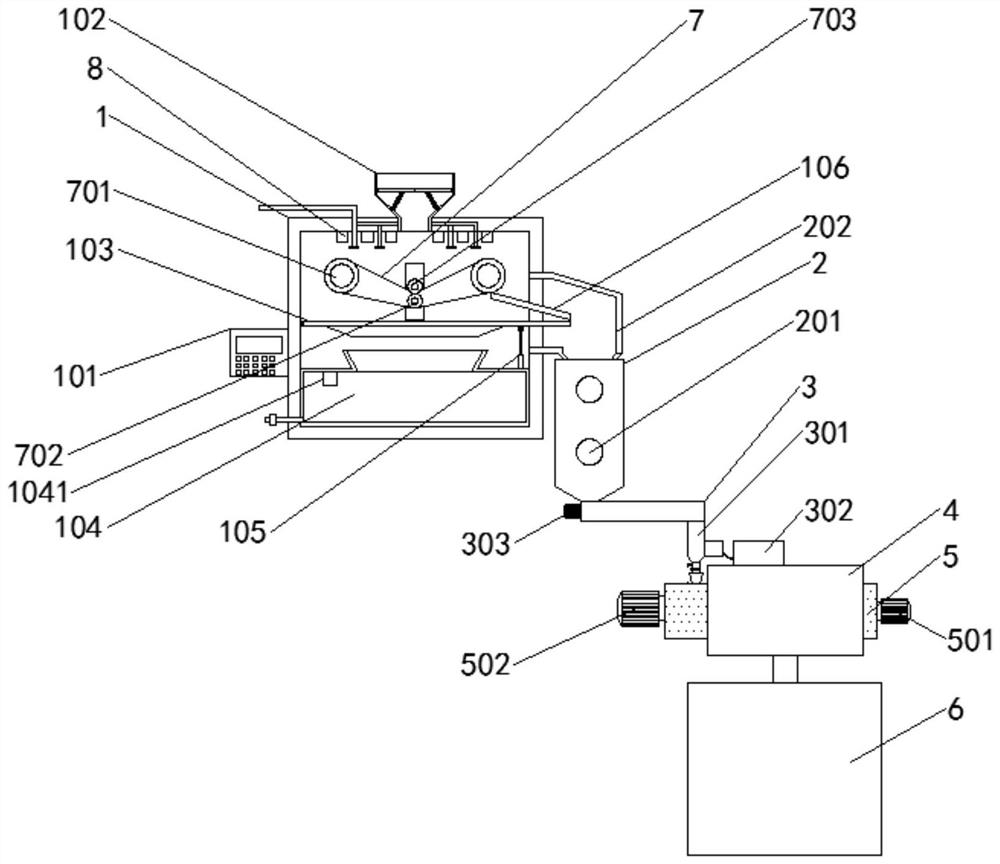

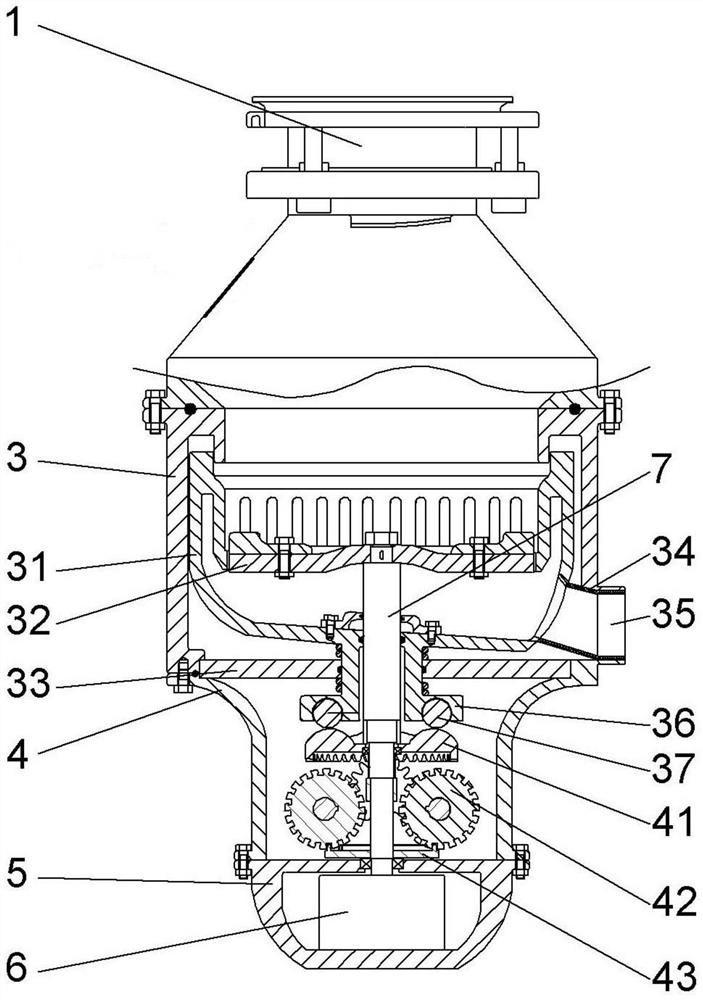

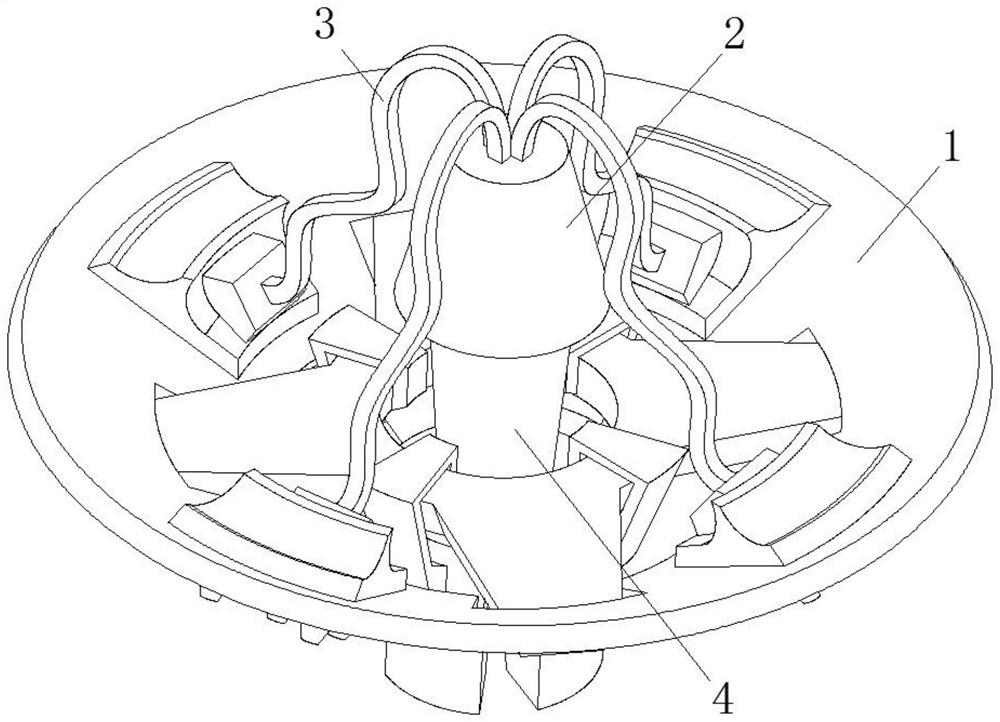

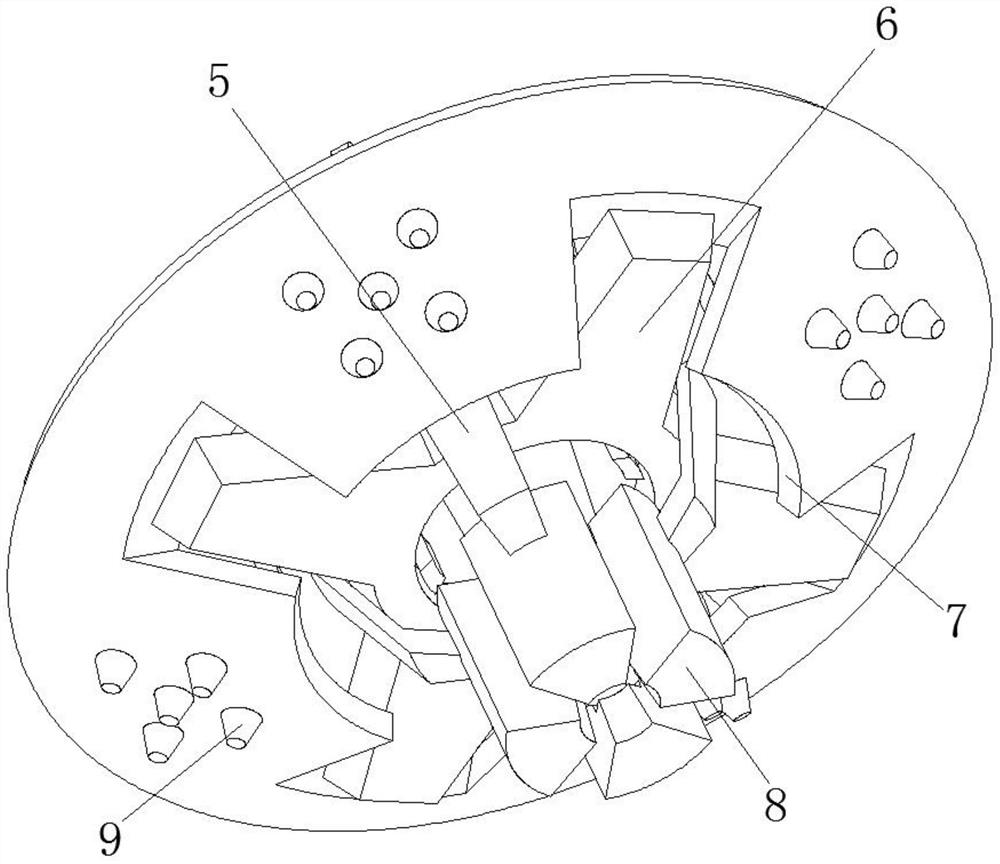

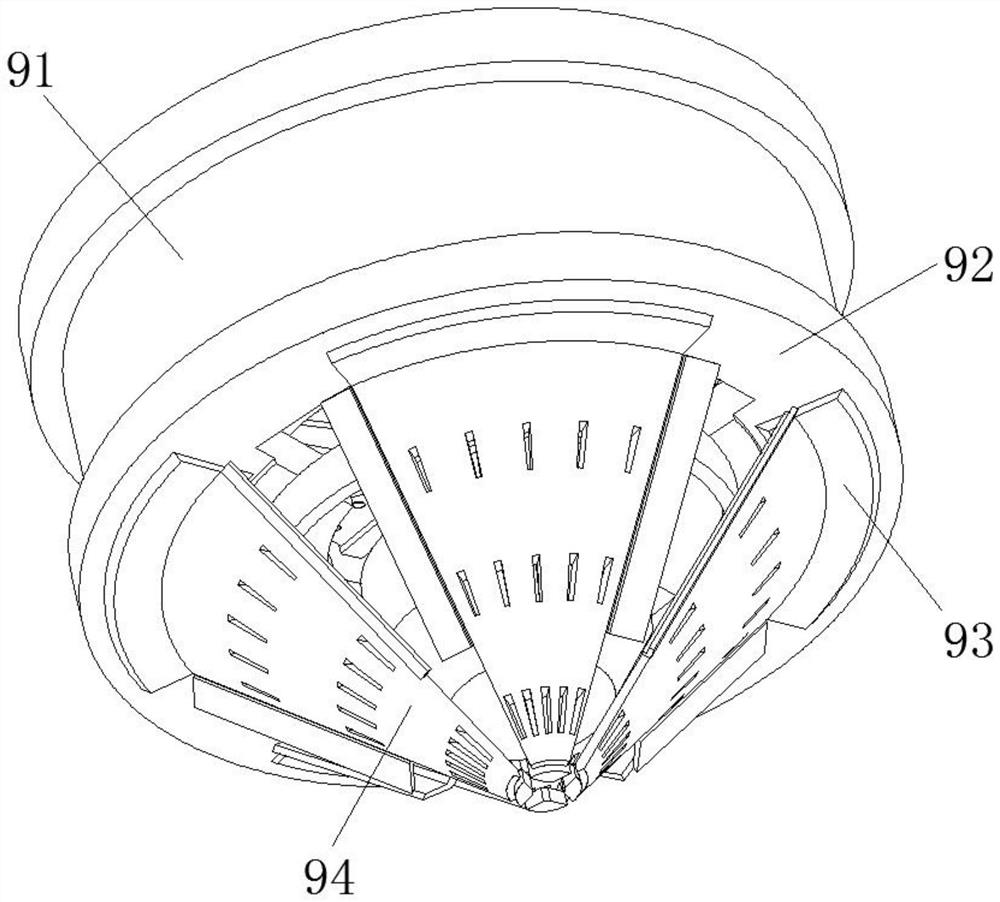

Environment-friendly kitchen waste processor with self-cleaning capacity and vibration device

ActiveCN112871349AAchieve vibration effectSelf-cleaning abilityClimate change adaptationGrain treatmentsEngineeringRefuse Disposals

The invention relates to the field of kitchen waste disposers and vibration devices, in particular to an environment-friendly kitchen waste disposer with self-cleaning capacity and a vibration device. The environment-friendly kitchen waste processor with the self-cleaning capacity comprises a shell, a shaft sleeve, a grinding mechanism and a vibration device, wherein a grinding space is formed in the shell; the grinding mechanism is arranged in the grinding space and comprises a grinding frame and a grinding disc; the vibration device comprises a speed change assembly, a vibration assembly and a differential assembly; the vibration assembly comprises a vibration block and a rotating disc; the vibration block is fixedly connected to the grinding frame; the upper surface of the rotating disc is a concave-convex surface, and when the rotating disc rotates, the concave-convex surface drives the vibration block to move up and down; the differential assembly is configured to transfer two rotational outputs to the rotating disc. The grinding frame is driven by the vibration device to vibrate, the kitchen garbage is separated in a vibrating mode and is prevented before being adhered, so that the self-cleaning capacity is achieved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Intensive fishery breeding device

PendingCN113826575AOptimize baitImprove feeding effectClimate change adaptationPisciculture and aquariaInternal cavityEngineering

The invention discloses an intensive fishery breeding device. The intensive fishery breeding device comprises a protection plate, a limiting hole is formed in the bottom of the protection plate, a bottom supporting plate is fixedly connected to the bottom of the inner cavity of the limiting hole, the surface of the bottom supporting plate is sleeved with a limiting rod, and a floating air bag is fixedly connected to the bottom of the limiting rod. The upper surface of the protection plate is fixedly connected with an output pipe, the top end of the output pipe is fixedly connected with a first pressurizing shell, the bottom of the first pressurizing shell is sleeved with a second pressurizing shell, the second pressurizing shell is matched with the upper surface of the floating air bag, and the lower surface of the protection plate is fixedly connected with a material scattering device. The invention relates to the technical field of fishery breeding. According to the intensive fishery breeding device, the breeding device is placed on a water surface, when a worker needs to operate the breeding device, the worker pressurizes the one-way floating air bag, the floating air bag conducts one-way air extrusion, and spraying and scattering are automatically conducted on an one-way water surface area.

Owner:李春生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com