Vacuum pump buffer tank

A buffer tank and vacuum pump technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of inability to mix gas, increase the time of gas mixing, and inability to buffer gas multiple times, achieving a good buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

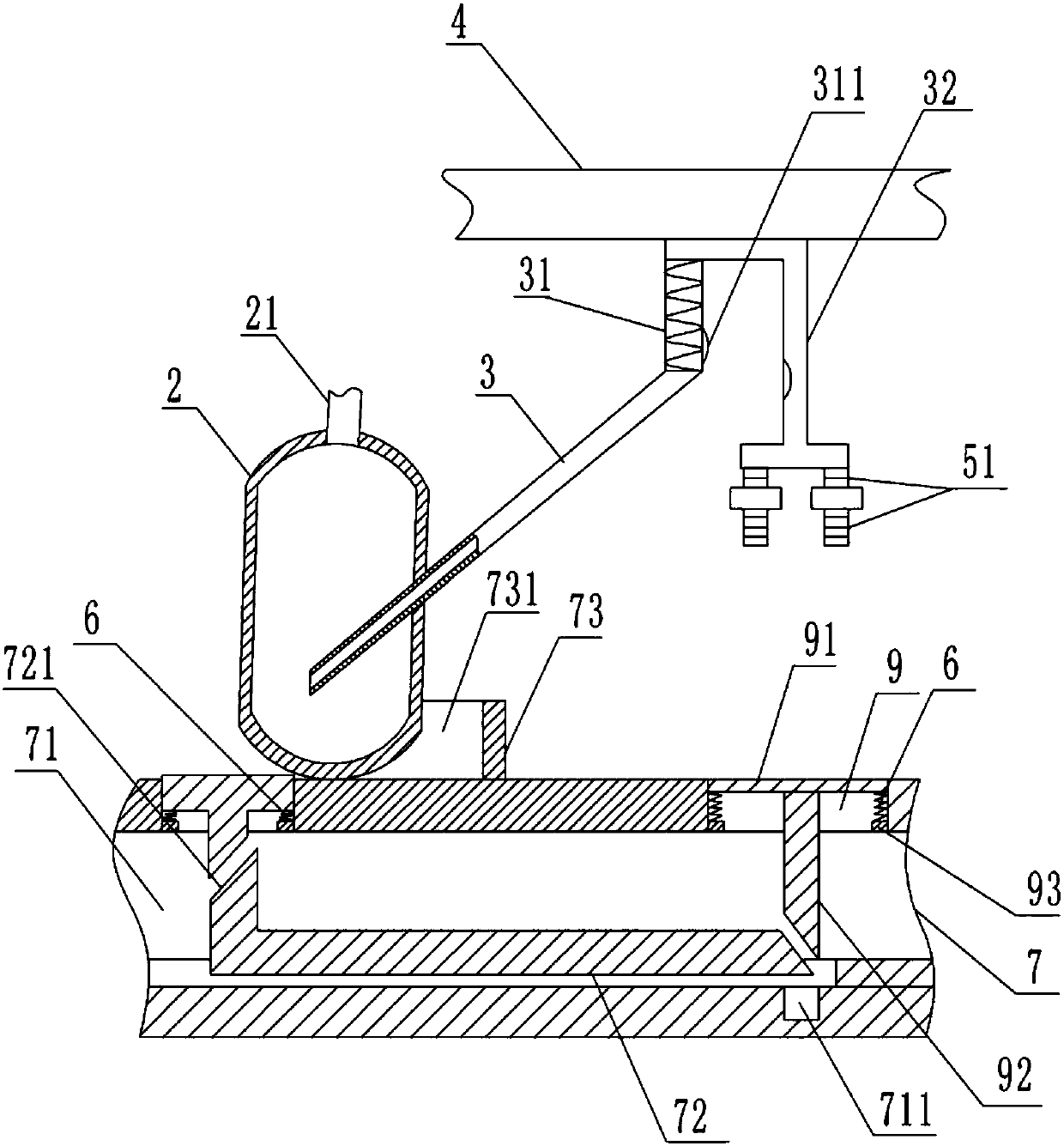

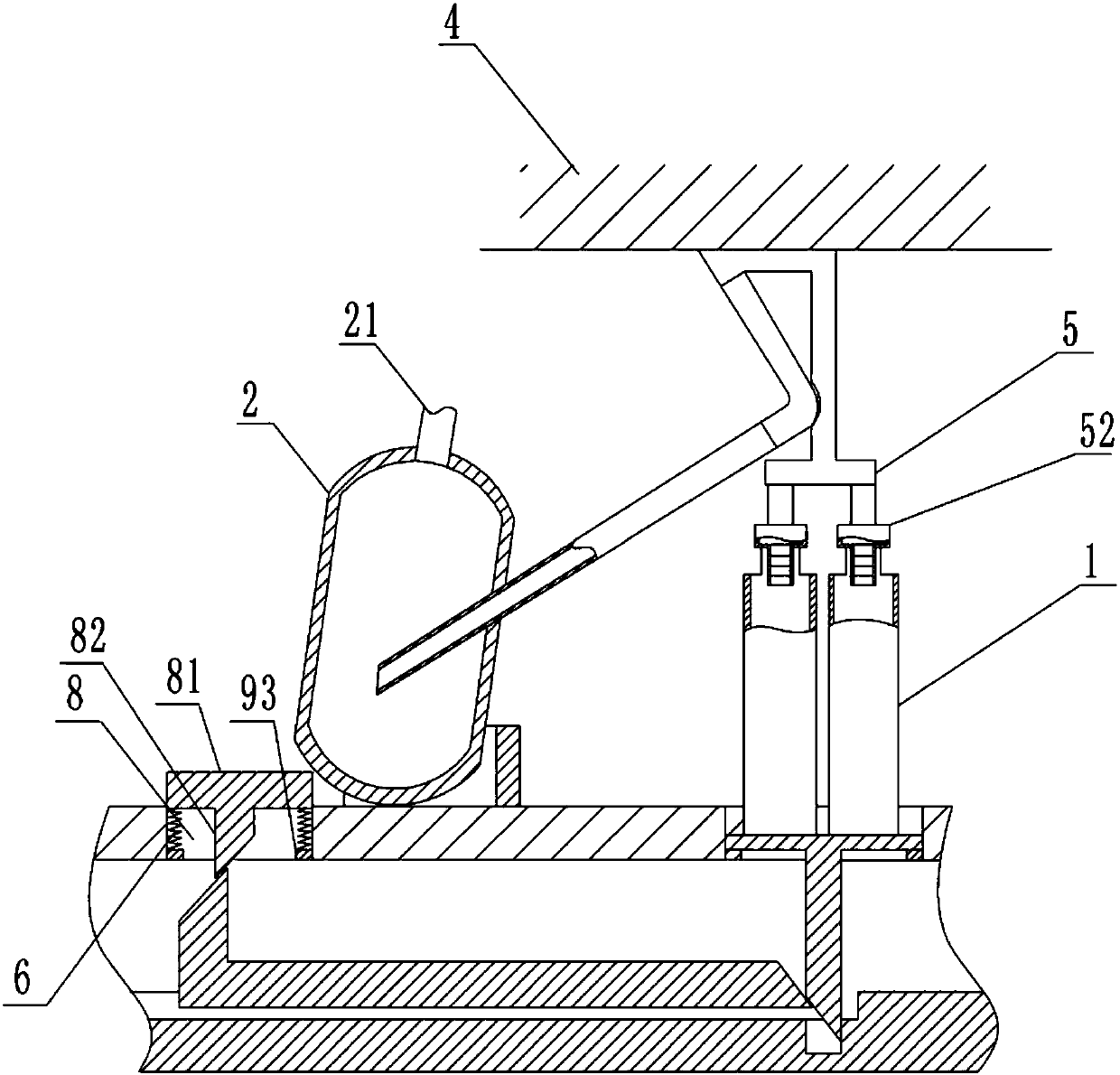

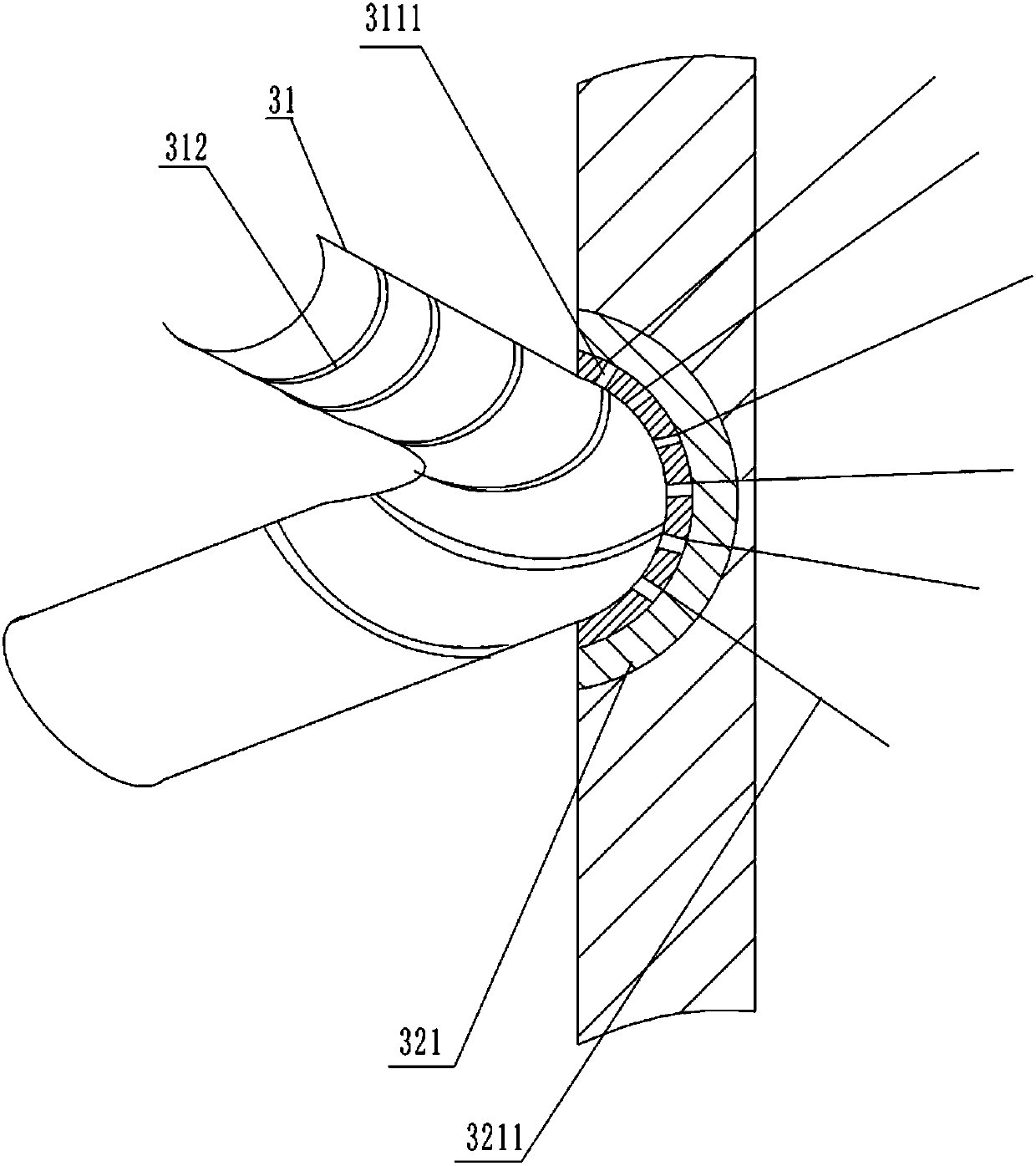

[0022] The reference signs in the drawings of the description include: gas tank 1, buffer tank body 2, air outlet pipe 21, first pipe 3, elastic telescopic tube 31, first magnet 311, through hole 3111, sheet-shaped protrusion 312, third Pipeline 32, second magnet 321, vibrating plate 3211, fixed part 4, suction plate 5, elastic tube 51, chuck 52, return spring 6, placement plate 7, sliding chamber 71, slot 711, sliding rod 72, top Out rod 721, positioning block 73, arc mouth 731, push cavity 8, push block 81, push rod 82, place cavity 9, place block 91, place bar 92, retaining ring 93.

[0023] In order to achieve the above object, the basic scheme of the present invention is as follows:

[0024] like figure 1 , figure 2 and image 3 As shown, a buffer tank for a vacuum pump includes a buffer pipeline and a buffer tank body 2 inclined downward toward the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com