Equipment for building construction

A construction and equipment technology, applied in the field of mortar manufacturing, can solve the problems of large particles, low work efficiency, and long sand making time, and achieve the effect of avoiding excessive damage, high work efficiency and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

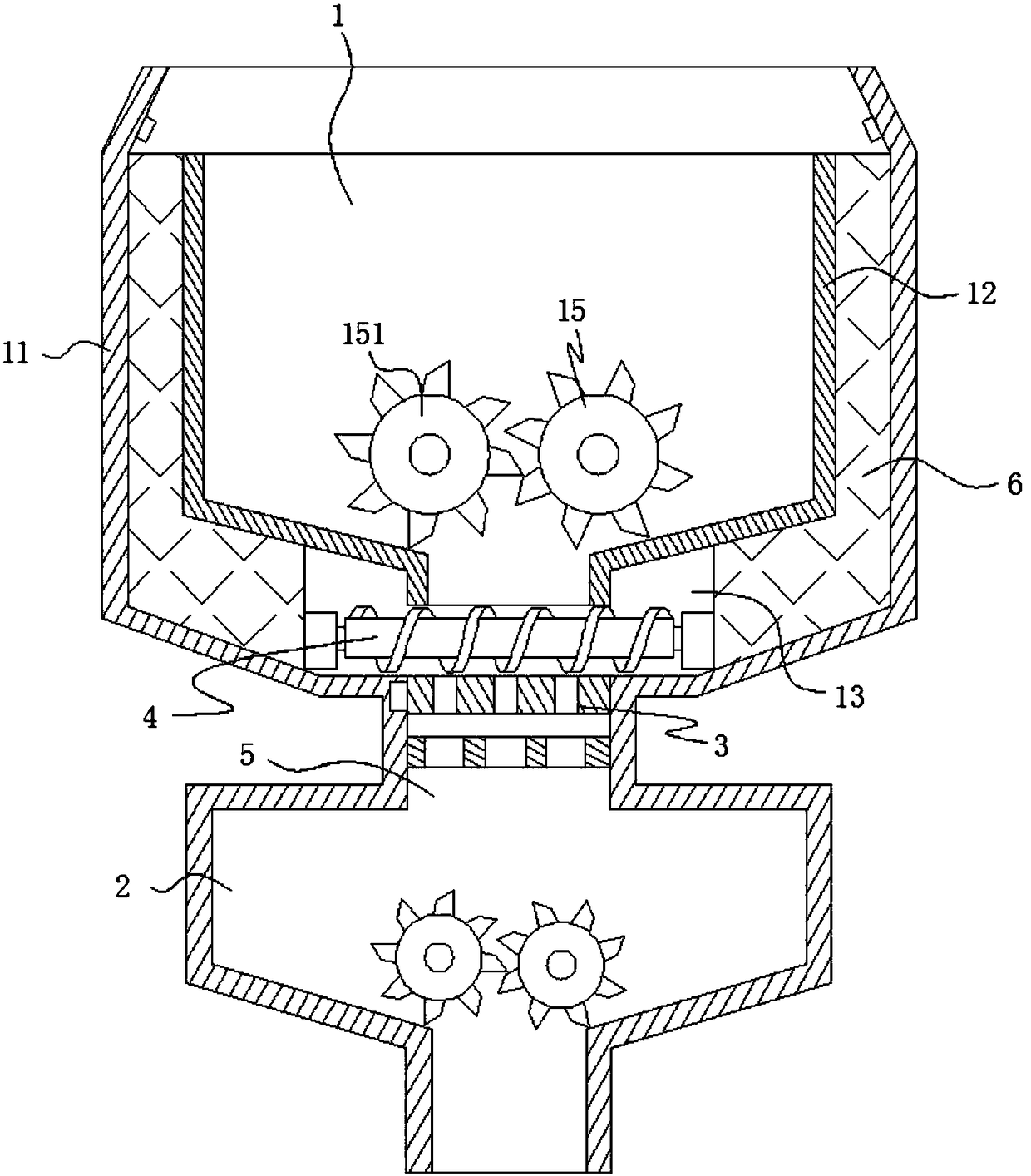

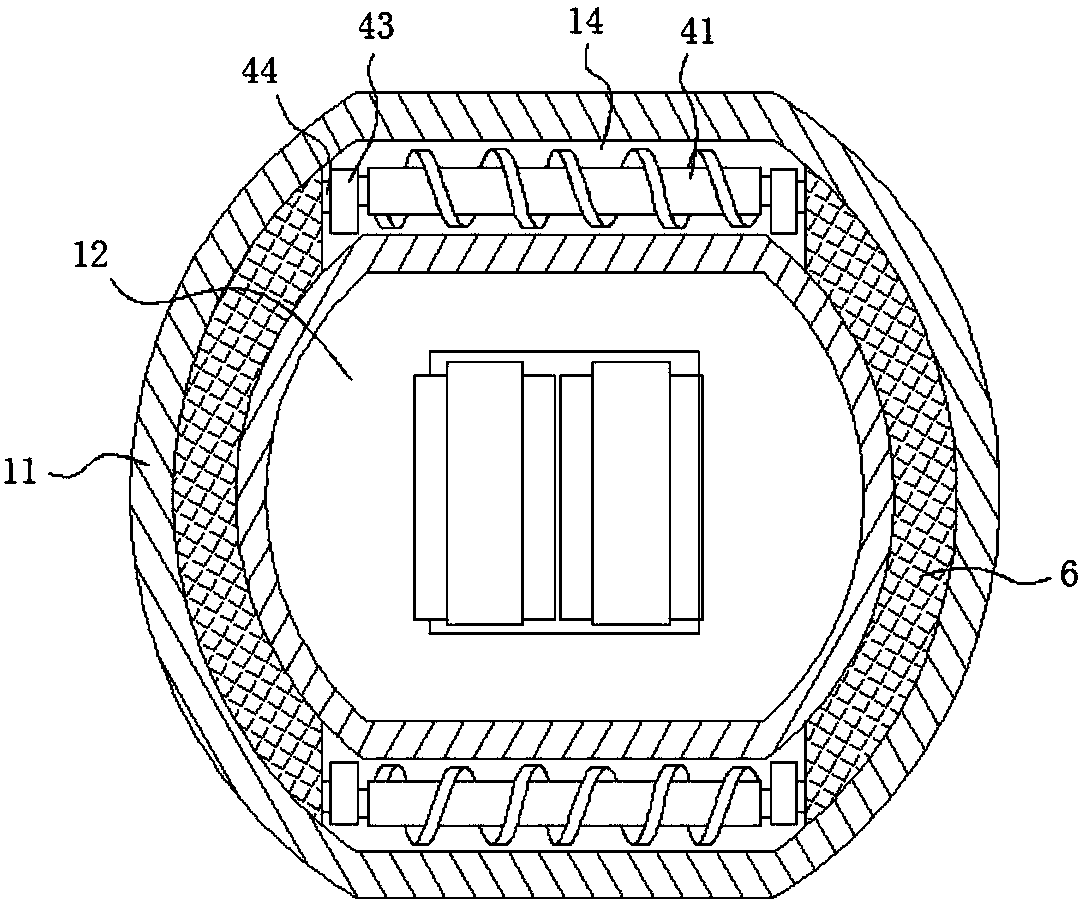

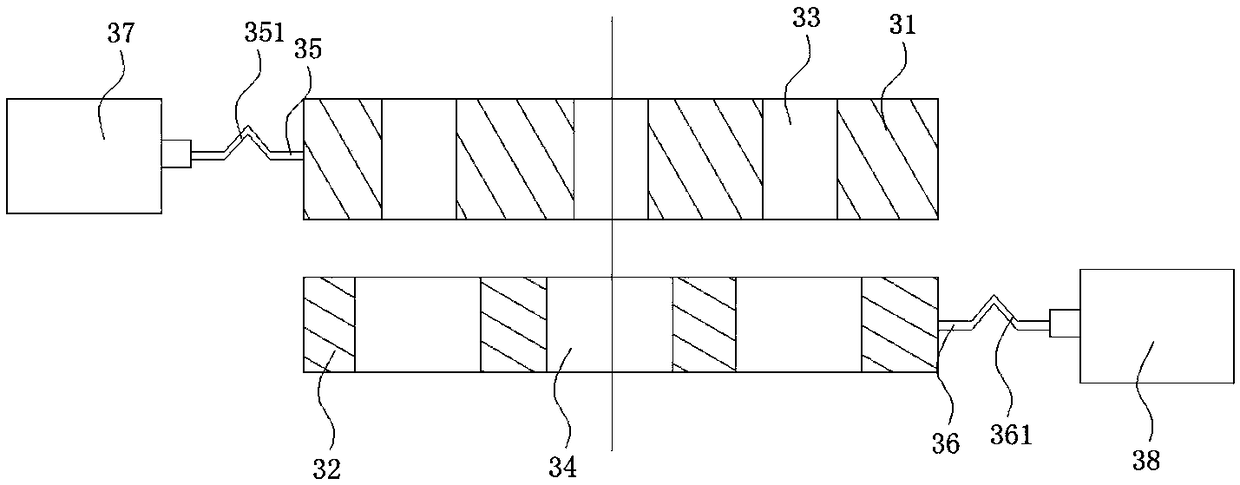

[0020] Such as Figure 1-5 As shown, a kind of equipment for building construction is used for mortar preparation, including a primary processing chamber 1 and a secondary processing chamber 2, and the secondary processing chamber 2 communicates with the primary processing chamber; the primary processing chamber 1 includes The housing 11 and the inner processing chamber 12 arranged in the housing, a recovery channel 13 is formed between the inner processing chamber 12 and the housing 11; specifically, the left and right sides of the inner processing chamber 12 are respectively provided with There is a connecting part 6, and the two connecting parts 6 are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com