Ultrasonic-assisted vibration multi-point mold support rotary forming device

An auxiliary vibration, multi-point mold technology, used in forming tools, manufacturing tools, transportation and packaging, etc., can solve the problems of high scrap rate, low production efficiency, surface defects of profiles, etc., to reduce surface wrinkles and improve product quality Quality, the effect of extending the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

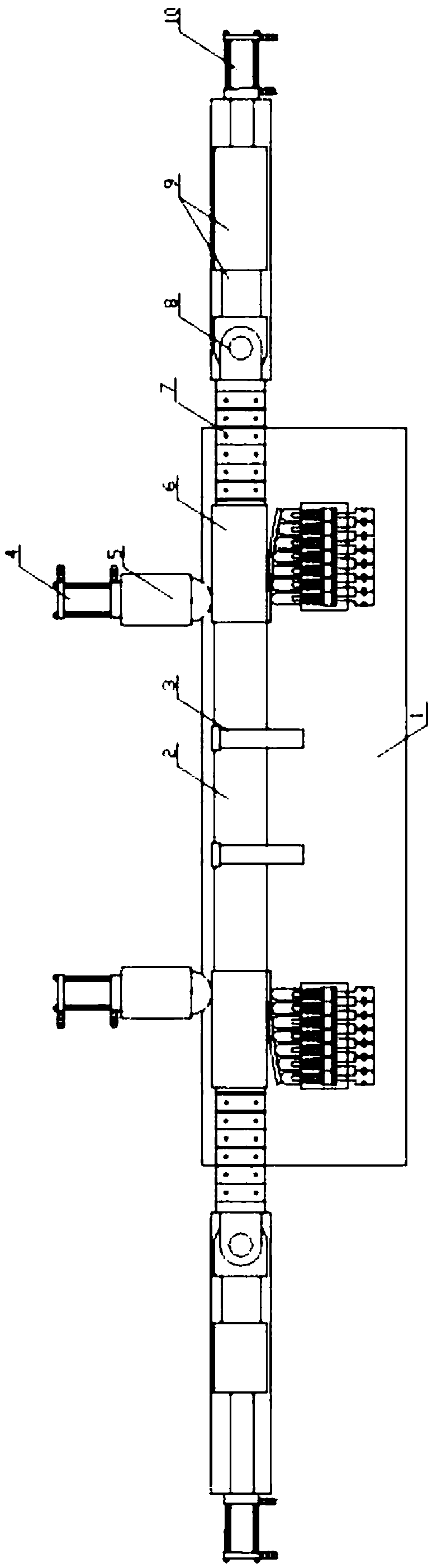

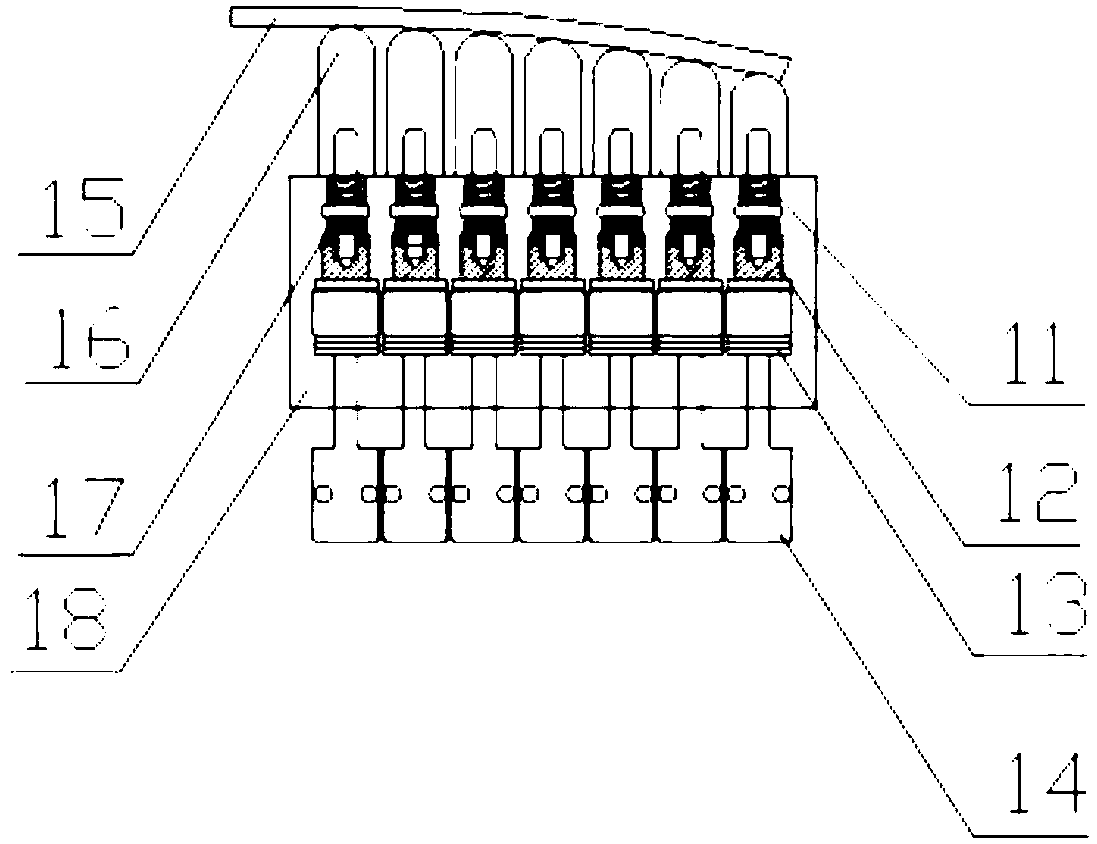

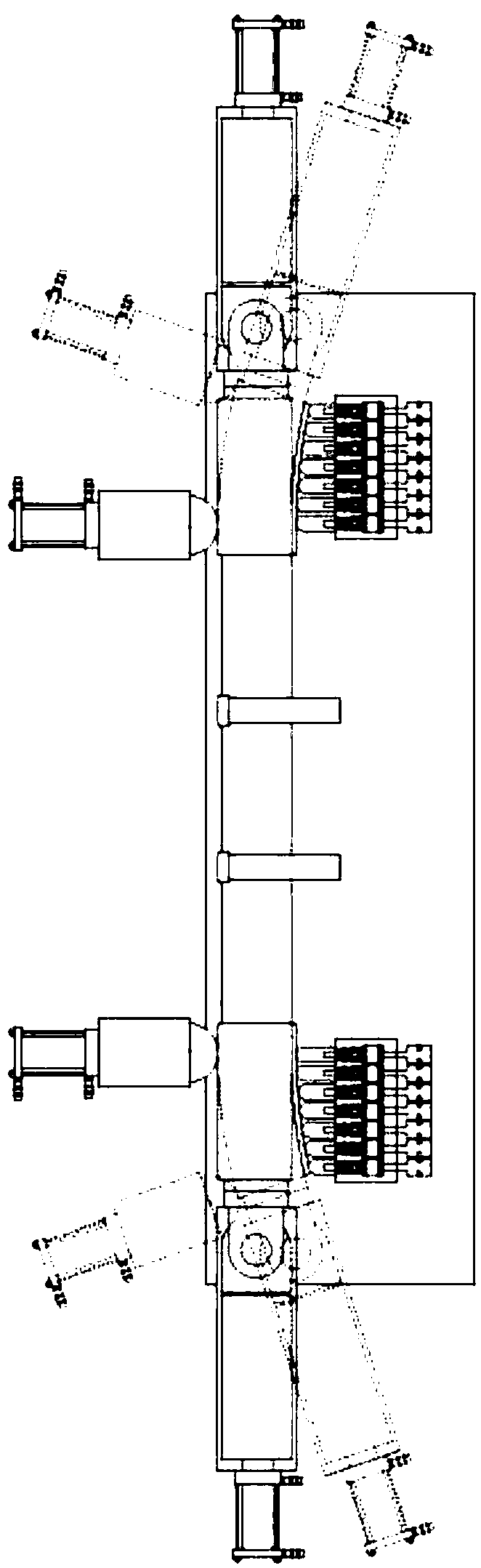

[0018] Ultrasonic-assisted vibration multi-point mold support rotary forming device, such as figure 1 with figure 2 As shown, it includes a workbench 1, a profile 2, a forming mechanism I and a forming mechanism II, and the profile 1 is fixedly arranged on the workbench 1 through two profile clamps 3; the structure of the forming mechanism II is the same as that of the forming mechanism I, and The mirror image is symmetrically arranged at both ends of the profile 2; the forming mechanism I includes pressure roller hydraulic transmission and force application device 4, pressure roller 5, guard plate 6, mandrel 7, hinge device 8, sleeve 9, mandrel hydraulic transmission Device 10, spring 11, horn 12, transducer 13, ultrasonic generator 14, elastic pad 15, moldless multi-point mold 16, spring damper 17 and mold base 18; Core mold 7, sleeve 9 and core mold hydraulic transmission device 10, core mold 7 and core mold hydraulic transmission device 10 are connected by hinge device 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com