Connecting rod type reciprocating vibration control system

A vibration control, link-type technology, applied in the control system, motor control, DC motor speed/torque control, etc., can solve the problems of unable to generate vibration at the same time, unable to provide the effect of vibration, unable to adjust the speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

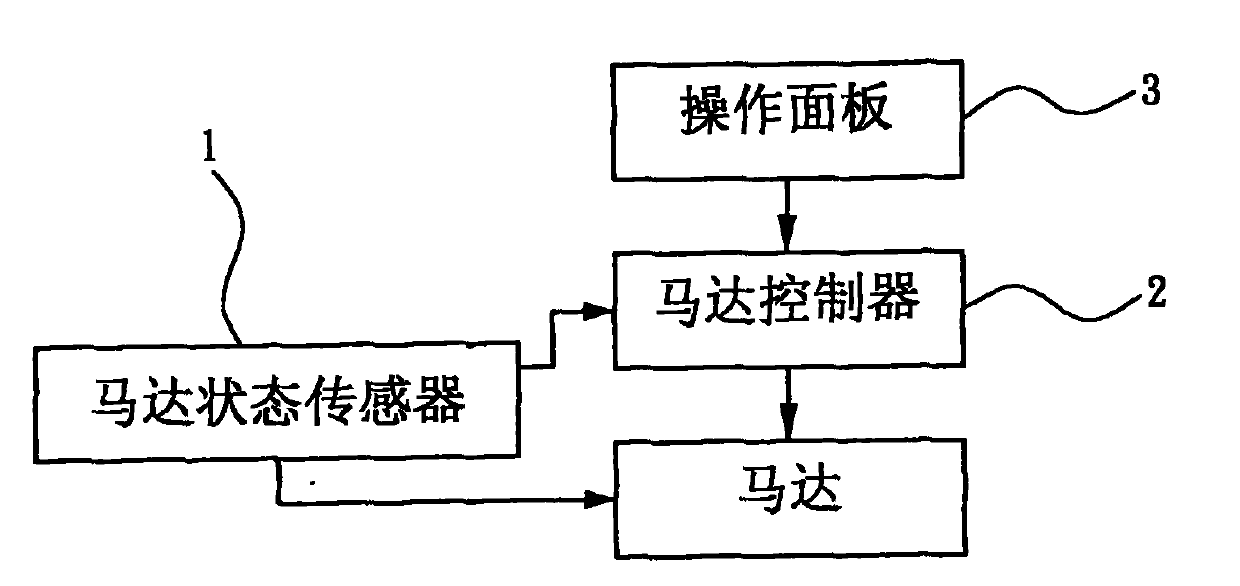

[0035] see figure 1 As shown, the "connecting rod type reciprocating vibration control system" of the present invention includes a motor state sensor 1, a motor controller 2 and an operation panel 3;

[0036] The motor state sensor 1 is pivotally connected to an appropriate position of the motor. The motor state sensor 1 is used for sensing the rotation angle or speed of the motor. The motor controller 2 is electrically connected to the motor state sensor 1 and the motor. The motor The controller 2 is used to control the rotation speed of the motor, and the operation panel 3 is used for the user to set data on the motor controller 2;

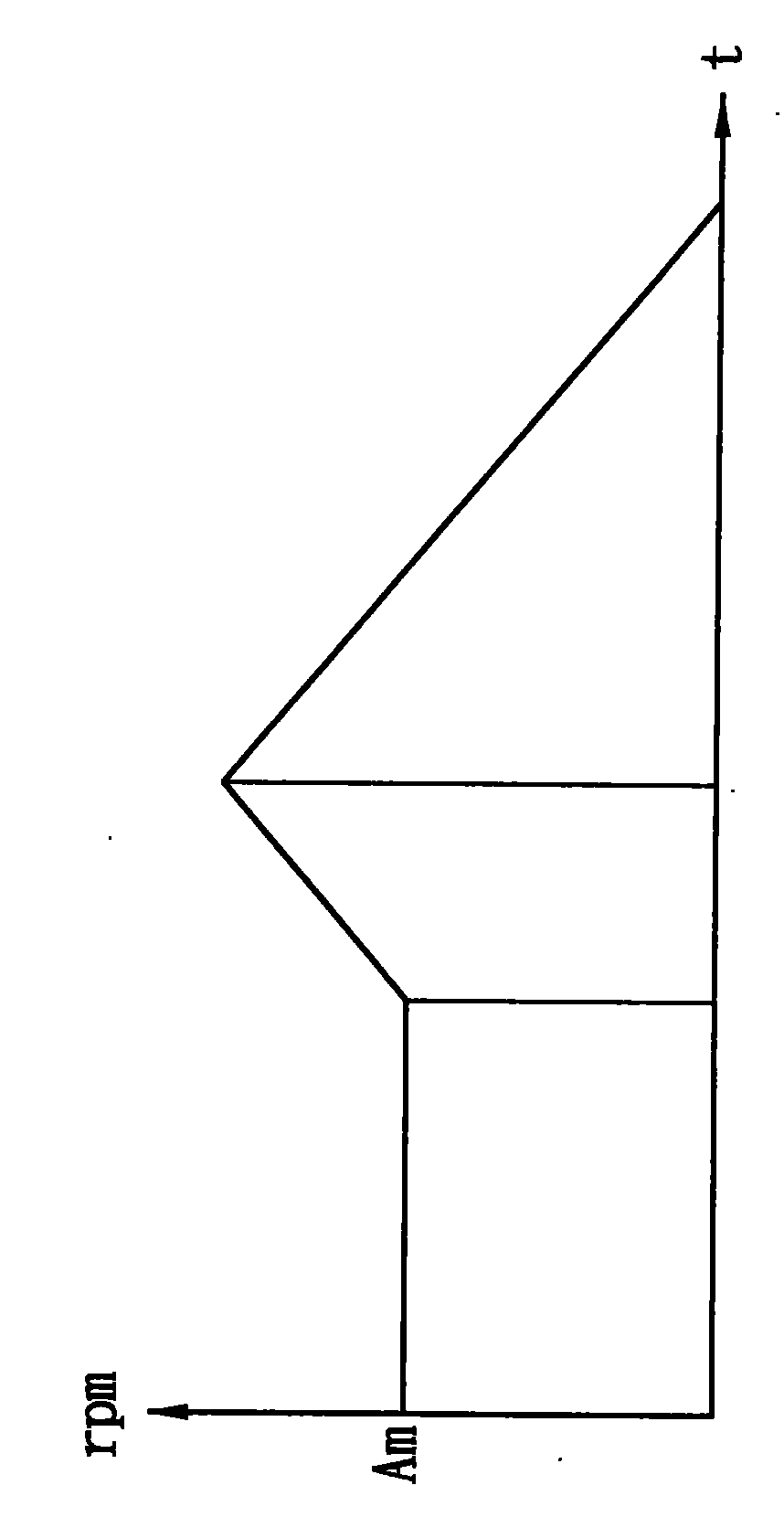

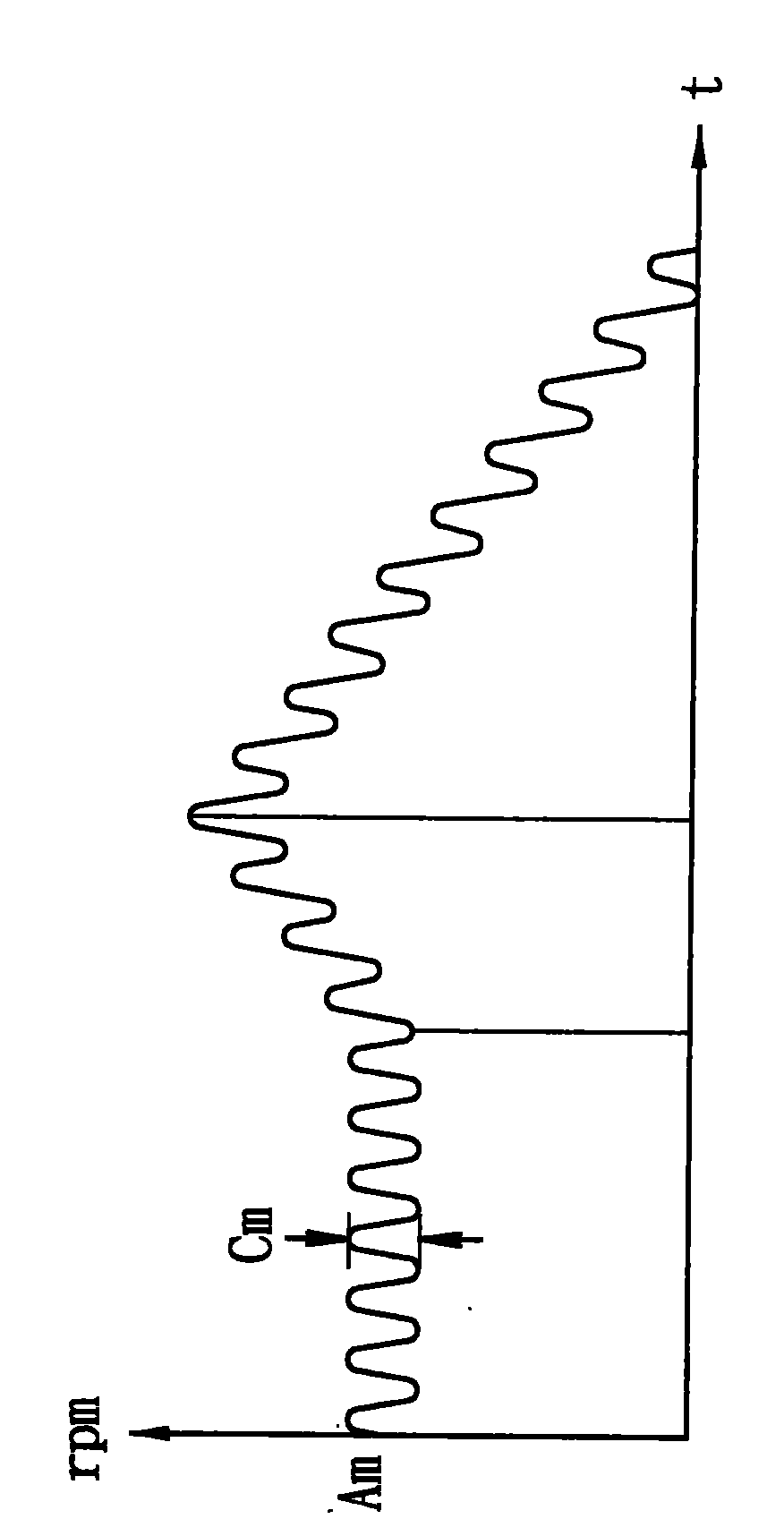

[0037] In this way, the motor controller 2 can control the rotation speed of the motor according to the data set by the operation panel 3, and by adding a speed ripple when setting the rotation speed of the motor, the speed ripple can affect the rotation speed The speed difference is generated when the motor is running, so as to achieve the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com