Waste recovery device for constructional engineering

A technology of waste recycling and construction engineering, which is applied in transportation and packaging, solid waste removal, filtering and screening, etc., and can solve problems such as inability to recycle metal materials, waste of resources, and unsatisfactory crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

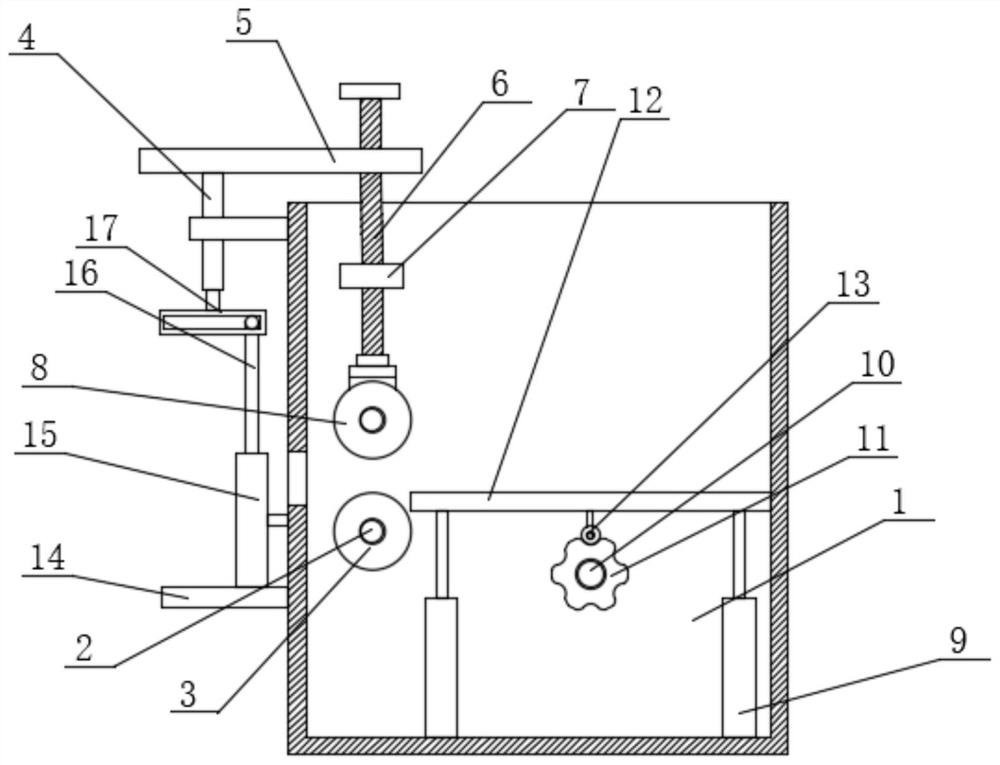

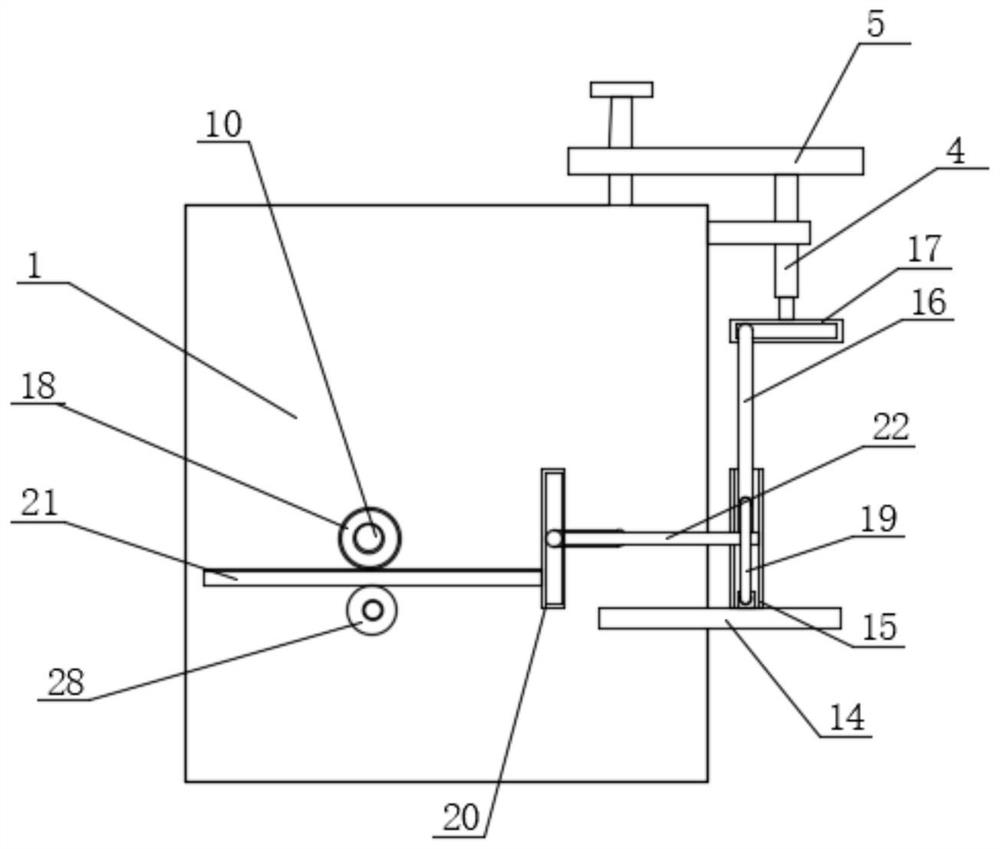

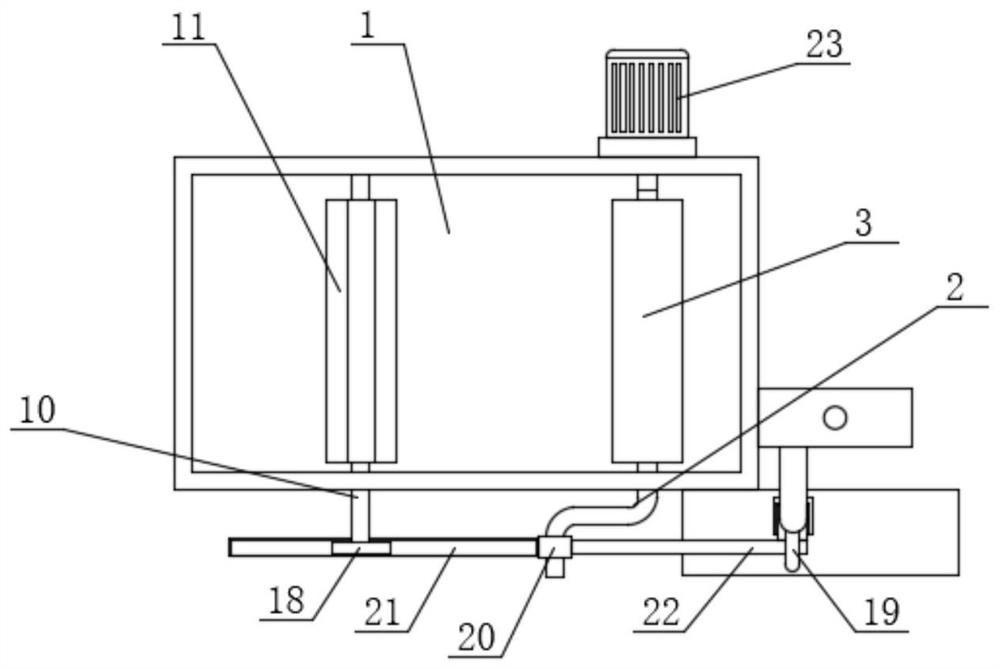

[0025] The present invention will be further explained below in conjunction with specific embodiments.

[0026] refer to Figure 1-6 , a kind of construction waste recycling device is proposed in the present embodiment, comprises smashing box 1, offers feed hole on the left side inner wall of smashing box 1, and the front side of smashing box 1 is fixedly installed with driving motor 23, and drives The output shaft of the motor 23 extends into the crushing box 1 and is fixedly equipped with a Z-shaped rod 2. The Z-shaped rod 2 is fixedly sleeved with a support roller 3, and the rear end of the Z-shaped rod 2 extends to the rear side of the crushing box 1. A sieve plate 12 is slidably connected in the box 1, and a mobile cover 4 is slidably connected to the top left side of the crushing box 1. A support plate 5 is fixedly installed on the top of the mobile cover 4, and a screw rod 6 is threaded on the support plate 5. The bottom end extends into the crushing box 1 and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com