Ultra-high performance material distributing machine for concrete bridge deck construction and construction method of ultra-high performance material distributing machine for concrete bridge deck construction

An ultra-high performance, concrete technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as uneven distribution, and achieve the effect of ensuring quality, facilitating discharge, and avoiding clogging or sticking to walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

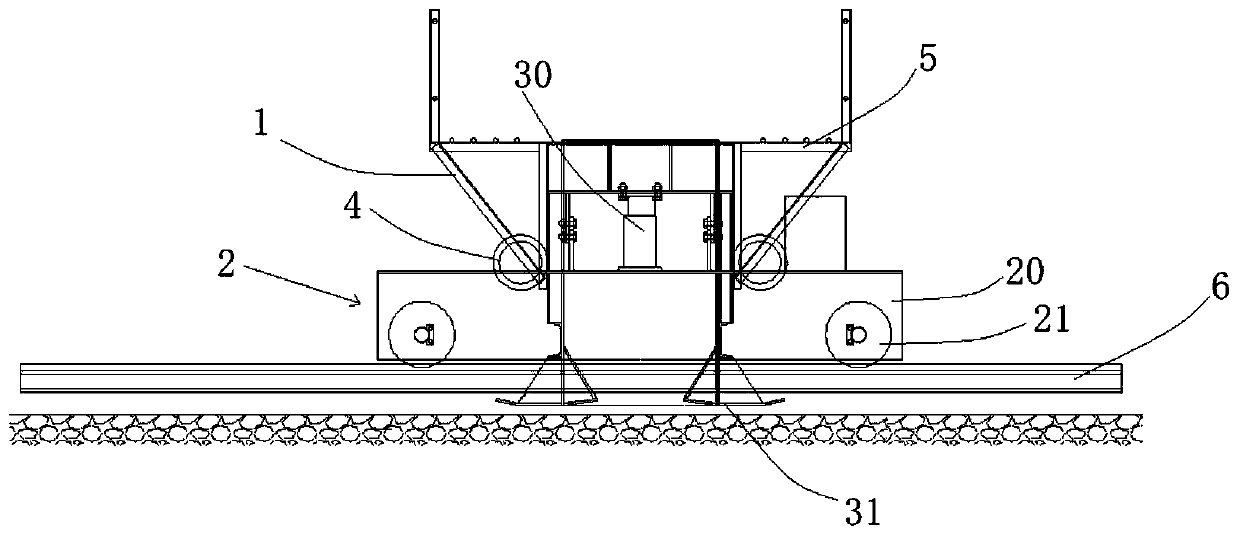

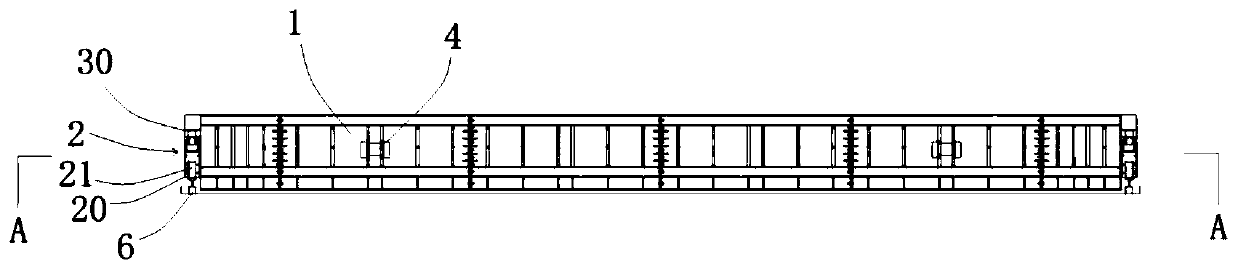

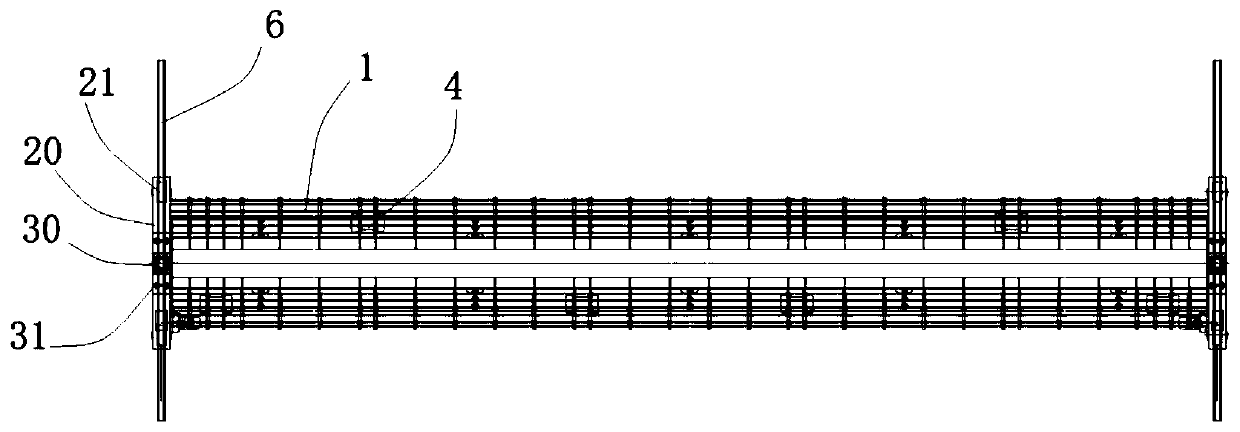

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see Figure 1-Figure 2 As shown, the embodiment of the present invention provides a distribution machine for ultra-high performance concrete bridge deck construction, which includes a material box assembly, a scraping assembly and a walking assembly 2, wherein the material box assembly includes at least one bottomless material box 1, The bottomless material box 1 is used for loading and unloading ultra-high performance concrete; the scraping and adjusting assembly includes at least two adjusting parts 30 and at least one scraping and adjusting plate 31, and the two adjusting parts 30 are respectively arranged on one side of the bottomless material box 1, and the scraping and adjusting The plate 31 is set at the bottom of the bottomless material box 1, and the adjustment member 30 is mainly used to adjust the height of the bottomless mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com